When designing a foundation, it is important to choose the right reinforcement, as this ensures the strength and durability of the structure. Currently, there are several important factors to consider when selecting reinforcement. First of all, the variety of reinforcement grades can be confusing, but knowing the basic characteristics will help make the right choice.

Reinforcement is made from low-alloy steel and comes in various diameters — from 6 to 32 mm. For foundations, reinforcement with a diameter of 10-16 mm is used. It provides the structure with the necessary strength due to its high tensile strength. Attention should also be paid to the grade of reinforcement, as grade A500C, which has a tensile strength limit of 500 MPa, is the most commonly used in construction.

Interesting! Reinforcement can have different types of coatings: ordinary, galvanized, or polymer, which provide additional protection against corrosion.

No less important is the choice between ordinary and spiral reinforcement. Spiral reinforcement provides greater flexibility and better adapts to loads, making it ideal for specific operating conditions.

Here are some basic recommendations for choosing reinforcement for the foundation:

- Determine the load: Calculate how much weight the foundation will bear and choose the appropriate reinforcement.

- Selection by standards: Ensure that the reinforcement meets state standards and certifications.

- Cost: Compare prices from different suppliers, but do not forget about quality!

The right choice of reinforcement will not only increase the stability of your foundation but also extend the service life of your building. Therefore, saving on quality can lead to much greater expenses in the future.

Considering all these factors, you will be able to choose the best reinforcement for your foundation, which will be the guarantee of the reliability and durability of your structure. 😊

Types of Reinforcement for Construction

When choosing reinforcement for construction, it is important to understand that there are several types, each with its significant features and areas of use. This can affect the overall quality and reliability of your project. Let’s consider the main types of reinforcement used in the construction field.

1. Ordinary Reinforcement — this is the most common type, made from ordinary low-alloy steel. Its main characteristic is high tensile strength. Ordinary reinforcement is often used in foundation work, provided that the operating conditions do not involve high corrosion risks.

2. Galvanized Reinforcement — has a special protective coating that prevents corrosion. This makes it particularly attractive for use in regions with high humidity or in conditions where the foundation may come into contact with aggressive substances. Its cost is somewhat higher, but investments in quality are fully justified.

3. Polymer Reinforcement — made from composite materials that are corrosion-resistant and weigh less compared to steel. Such reinforcement is ideal for construction in aggressive environments, although its mechanical properties still require further research.

4. Spiral Reinforcement — with curved shapes, which provides greater flexibility and resistance to stretching. The use of such reinforcement is usually appropriate in specific structures where adaptability to different loads is important.

5. High-Strength Steel Reinforcement — used for large-panel structures, bridges, or other structures with high strength requirements. This option is more expensive, but it undoubtedly guarantees higher load resistance.

6. Composite Reinforcement — made from plastic or fiberglass material, which is lightweight and corrosion-resistant. Such options are often used in architectural solutions and for manufacturing non-standard structures.

When determining which type of reinforcement is suitable for your project, do not forget to consider the operating features and loads on the foundation. 😄 It is also important to pay attention to certification and quality of materials, as this will help avoid unnecessary expenses in the future.

When choosing the design and planning of your building, understanding the different types of reinforcement will significantly simplify the entire process. So, while working on your project, review this information and consider all important aspects! 🏗️

Calculation of the Required Amount of Reinforcement

Calculating the amount of reinforcement for the foundation is an important step that can significantly affect the strength and durability of your building. Why is this so important? 🎯 Correctly determining the volume of reinforcement will help avoid both excessive costs and insufficient reliability of the structure. Let’s look at how to do this correctly.

First, it is necessary to determine what loads will act on the foundation. This includes the weight of the building, as well as additional loads such as roofing, furniture, and equipment. Usually, static analysis methods are used for calculations, but initially, a simple method based on preliminary calculations can be applied.

Steps for Calculation:

- Determine the dimensions of the foundation: Plan its width, length, and height. The larger the foundation, the more reinforcement is needed.

- Calculate the volume of concrete: By multiplying the length, width, and height, we obtain the total volume in cubic meters.

- Determine the amount of reinforcement: Usually, the formula used is:

Total mass of concrete (m³) × reinforcement norm (kg/m³)

The reinforcement norm varies depending on the type of foundation and project features, but usually lies within 100-200 kg per cubic meter of concrete.

For example, if we have a foundation measuring 5 m x 5 m x 0.5 m, the volume of concrete equals 12.5 m³. With a reinforcement norm of 150 kg per m³, we need:

12.5 m³ × 150 kg/m³ = 1875 kg of reinforcement. 🏋️♂️

It is important to understand that different types of foundations may require different amounts of reinforcement. For example, a strip foundation usually has less load than a slab foundation. Also, consider that structural elements such as columns and walls may require additional reinforcement to ensure strength.

When you know the need for reinforcement, another important question is how to lay it. Incorrect laying can lead to a decrease in the strength of your foundation. Therefore, adhere to the correct installation technologies.

Here are a few points to pay attention to:

- Covering: The reinforcement should be placed at the correct distance from the edge of the concrete — usually 5 cm for protection against corrosion.

- Connections: Use welding or couplings to connect reinforcement bars to avoid weakening the structure.

- Placement: Place the reinforcement in the form of a grid or according to the scheme recommended by your project.

Do not forget that accurate calculation of the amount of reinforcement, its quality, and correct laying are key elements for ensuring the long-term reliability of your foundation. This process requires a detailed approach and consultations with experts. 🎓 This way, you can be sure that your choice of reinforcement will truly pay off!

Choosing Materials for Reinforcement

When choosing materials for reinforcement, it is important to consider not only its type but also the characteristics that affect the durability and strength of the structure. Among the main materials used for manufacturing reinforcement is iron, but the manufacturing and processing process can vary depending on the possible operating conditions of the reinforcement.

Steel is the most common material for reinforcement, as it has high tensile strength and is well distinguished by its ability to adapt to various loads. It is important to choose steel that withstands aggressive environments if your building is located in areas with high humidity or acidic environments. For such cases, types of reinforcement with special coatings, such as galvanized or polymer, are recommended. 😃

Another aspect of choosing materials is the physical processing of reinforcement. For example, reinforcement can be smooth or ribbed. Ribbed reinforcement provides better bonding with concrete and, accordingly, increases the structure’s resistance to various loads. Let’s consider a few important characteristics:

| Type of Reinforcement | Advantages | Disadvantages |

|---|---|---|

| Smooth Reinforcement | Easy to install, convenient for use in repair work | Less bonding with concrete |

| Ribbed Reinforcement | High resistance to shifts, improved bonding with concrete | Can be heavier to install |

Another important point is the operating environment. If your building will be exposed to corrosive factors, choose reinforcement with high anti-corrosion properties. For example, specially treated reinforcement with a polymer coating can be the optimal choice. Due to its resistance to destruction, such reinforcement withstands aggressive factors, thereby extending the service life of the structure. 🌍

When choosing the ideal reinforcement, do not forget about details such as its smoothing, grade, and diameter. The grade of reinforcement determines its tensile strength, while the diameter determines the load it can withstand. Accordingly, for foundations, it is better to use reinforcement with a diameter of 12 to 16 mm.

The choice of materials from which reinforcement is made will directly affect the reliability of your foundation and, in general, the safety of your building. An incorrect choice can lead to serious consequences in the future. Therefore, it is important to study all available options, focusing on the specifics of your project, taking into account loads and operating conditions. 💪

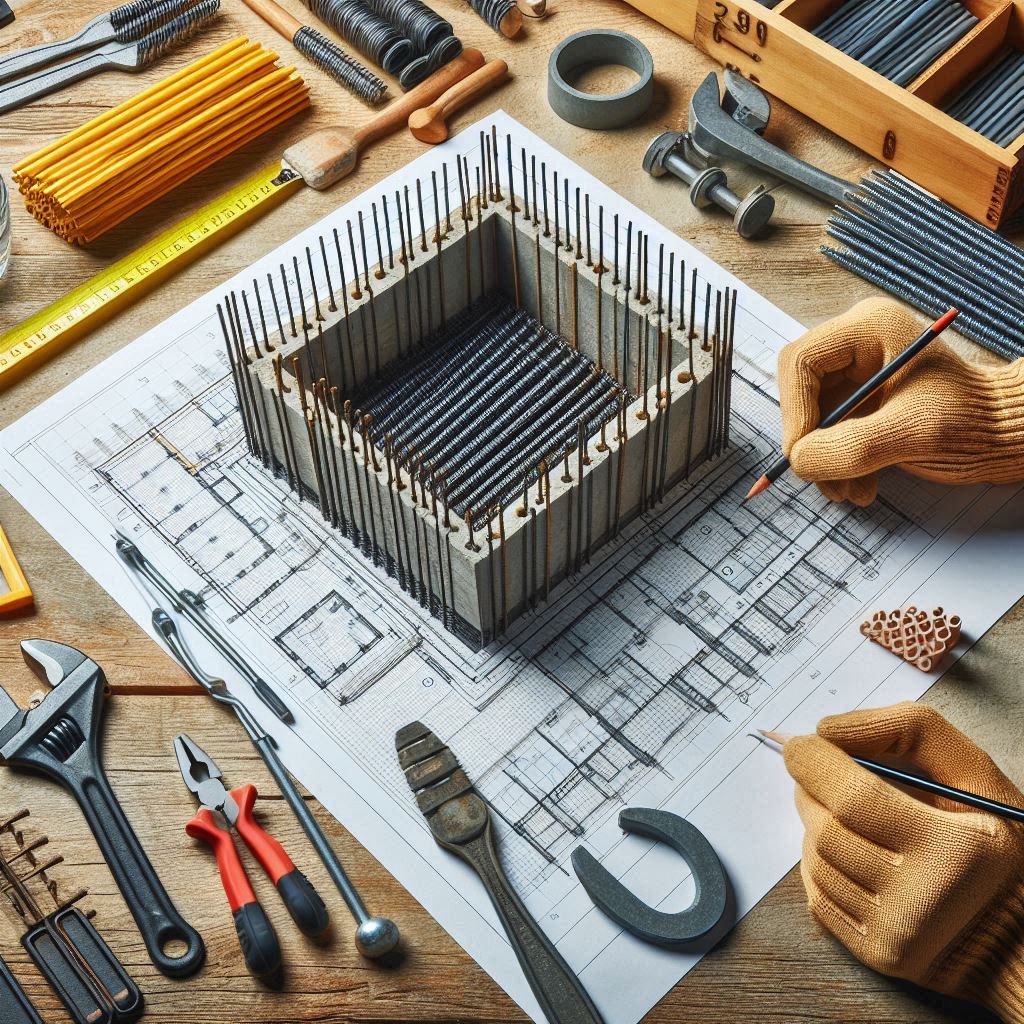

Technology of Laying Reinforcement in the Foundation

The technology of laying reinforcement in the foundation is a process that includes many nuances that should be considered to ensure the strength and durability of the structure. 🙌 Proper placement of reinforcement is critically important for guaranteeing the safety and stability of your building. Let’s consider how to properly organize the laying of reinforcement so that your project is successful.

Here are a few key stages of laying reinforcement:

- Preparation of the base: Before laying the reinforcement, it is important to prepare the foundation slab. The bottom of the pit must be leveled and compacted to avoid settling.

- Choosing reinforcement: As mentioned earlier, the choice of reinforcement should be justified, taking into account its grade, diameters, and coatings. Next, calculations should be made to determine the required amount.

- Reinforcement sheets: Cut the reinforcement into pieces of the required length according to your project. Usually, a grid of horizontal and vertical bars is used.

Installation of reinforcement: Before starting the laying, it is important to know that the reinforcement should be raised 5 cm above the bottom to be deeper embedded in the concrete. This will provide additional protection against corrosion.

The next step is to connect the reinforcement elements. Here, it is necessary to use connection methods that meet the requirements of your project:

- Binding: Using wire to tie the reinforcement is a traditional option that ensures reliability.

- Welding: Used to connect bars, but requires special equipment and experience.

- Couplings: Special couplings can also be used to connect reinforcement, providing high strength of the connection.

Reinforcement laying schemes: There are several standard laying schemes, but your choice should be based on specific conditions and loads. A typical reinforcement grid may look like this:

| Scheme | Description |

|---|---|

| Grid | Evenly spaced bars in horizontal and vertical directions. |

| Inverted “U” | Reinforcement arranged in the shape of “U”, providing additional rigidity. |

Do not forget the importance of monitoring the laying process. After completing the work, check whether each bar is correctly laid and whether there are any overlaps or loose elements. Inspection and control at the laying stage will help avoid problems in the future.

In addition, it is important to note that the reinforcement should be protected from contamination during installation. The presence of dirt, grease stains, oils, or paints can negatively affect the adhesion of concrete to the reinforcement. Therefore, if your reinforcement is exposed to external factors, consider additional coatings or treatments.

After laying, ensure adherence to technological processes when pouring concrete. Do not forget that the contacts between the reinforcement and concrete are the factor that forms the overall strength of your structure. By adhering to the correct technologies for laying reinforcement, you will ensure the reliability and durability of your foundation. 💪

Common Mistakes When Choosing Reinforcement

When choosing reinforcement for the foundation, it is important to avoid typical mistakes that can negatively affect the quality and strength of the construction. One of the most common mistakes is saving on the amount of reinforcement. Many builders or clients strive to reduce costs, which can lead to insufficient securing of the structure. Remember that insufficient reinforcement can cause cracks and destruction of the building in the future. ⚠️

Another common mistake is using low-quality reinforcement. Often, in order to reduce costs, cheap options are chosen that may not meet standards, reducing the overall strength of the structure. Do not forget that reinforcement is a strategically important element, and saving on its quality is not recommended. Ensure that the reinforcement you choose has the appropriate quality certificates and meets the standards accepted in your country.

In addition, it is important to pay attention to the correct laying of bars. Often, during the installation of reinforcement, the specified scheme is not followed; for example, the bars may be incorrectly placed or left too close to the edges of the concrete pour. This can lead to the reinforcement being unable to withstand loads, increasing the risk of corrosion or moisture exchange. When laying reinforcement, adhere to recommendations about the distance from the edge, less than 5 cm, to ensure reliable protection. 🛡️

Moreover, it is equally important to correctly connect the bars. Incorrect connections, such as insufficient fastening or using low-quality connections, can weaken the structure. Different connection methods, such as welding, binding with wire, or using couplings, have their advantages, and they should be chosen depending on the load and operating conditions. Properly connecting reinforcement is the key to the durability and reliability of your foundation.

Do not ignore the importance of checking the integrity of the reinforcement before installation. Bends, corrosion, or mechanical damage can critically affect the stability of the structure. Before starting installation, check each bar for defects. This will help avoid unforeseen situations during operation.

Pay attention to the storage conditions of the reinforcement before installation. If the bars have been stored outdoors, they may be subject to corrosion. Avoid contact with water and humid environments that can deteriorate their properties. Ideal storage is a dry, clean place with good ventilation.

Remember, even the smallest flaws in choosing and laying reinforcement can have serious consequences. By approaching the process responsibly and carefully, you can avoid typical mistakes and assemble a reliable, durable structure that will withstand any loads. 🤓

Care for Reinforcement After Installation

Care for reinforcement after installation is an important component of the construction process, as proper treatment and protection of the reinforcement can significantly extend the service life of the foundation. First of all, it is necessary to pay attention to corrosion control. Reinforcement that lacks appropriate coating or has been damaged during installation can become vulnerable to aggressive environmental factors such as humidity and chemicals.

Here are some tips for caring for reinforcement:

- Regular inspection: Conduct scheduled checks of the reinforcement to detect possible signs of corrosion. It is important to respond promptly to anything that may threaten the integrity of the structure.

- Protection from moisture: Do not allow water accumulation or constant moisture on the surface of the reinforcement. Use special materials for coating that provide effective protection against moisture.

- Preventing mechanical damage: Avoid careless handling of the reinforcement during construction work. The impact of possible blows or pressures can reduce its mechanical properties. 🛠️

Do not forget about proper storage of the reinforcement if installation is not yet complete. Keep the reinforcement in dry and protected places to avoid damage or deterioration. If the reinforcement is stored outdoors, wrap it in film or cloth to protect it from rain and sunlight.

There is also a possibility of using anti-corrosion agents, especially in cases where the reinforcement is at increased risk of corrosion. Special paints or varnishes designed for metals can provide an additional level of protection and prevent natural wear. 🌧️

Equally important is monitoring the moisture regime. Reinforcement that is in high humidity conditions can corrode even with protective coatings. Installing a moisture control system in the foundation area can help detect problems in a timely manner.

And do not forget about interaction with concrete. Ensure good adhesion between the reinforcement and concrete by avoiding the presence of contaminants on the surface that can reduce adhesive properties. If you find contamination, clean the reinforcement before completing the installation.

Thus, by following simple and clear rules for caring for reinforcement, you can ensure the reliability and strength of your foundation for many years. Only attention and a responsible approach to details can prevent unforeseen situations during the operation of your building! 🔍

Expert Tips for Choosing Reinforcement

When choosing reinforcement for the foundation, it is important to consider several key aspects that can significantly affect the quality of your structure. 🏗️ Before settling on a specific type of reinforcement, it is important to consult with specialists and take their recommendations into account. Here are some expert tips that will help you make the best choice:

- Assessment of operating conditions: Pay attention to the geological conditions of the construction site. If the area is subject to constant changes in humidity or has an aggressive environment, it is worth choosing reinforcement with anti-corrosion coating or composite options that are corrosion-resistant. 🌧️

- Ventilation and drainage: Ventilation and drainage systems can significantly extend the service life of the reinforcement. Plan them in advance to reduce the risk of water accumulation in the foundation area.

- Correct connections: When using couplings, welding, or binding, ensure that the connections are made according to the recommendations of the reinforcement manufacturers. Incorrectly made connections can provoke weakening of the structure. 🔗

- Use of certified materials: Always check the documentation for the reinforcement. Certification confirms compliance with standards. Reinforcement without certificates can lead to unforeseen consequences during operation. 📄

- Study of characteristics: Carefully study the technical characteristics of the reinforcement you choose. Ask suppliers about the grade, brand, and purpose of the material. The correct choice depends on the stability of your structure to the loads created.

Experts also advise avoiding spontaneous choices; base your decision on a detailed analysis of operating conditions and the available range. Do not hesitate to ask for advice from specialists — this is your investment, and the right choice will ensure the safety and reliability of your building for many years to come. 😇