Stainless steel has changed the world of industry and our lives. It is a special alloy that is highly resistant to corrosion and aggressive environments.

This material contains a lot of chromium (at least 10.5%). This has given it unique properties. Stainless steel has become a true revolution in metallurgy.

Its main feature is the ability to not break down and maintain its appearance for decades.

Key Findings

- Stainless steel contains at least 10.5% chromium

- The material is resistant to corrosion and aggressive environments

- Service life exceeds 50 years

- Used in various industries

- Provides high strength and reliability of structures

Definition of Stainless Steel

Stainless steel is a special alloy known for its strength and corrosion resistance. Types of stainless steel have a unique chemical structure. It ensures a long service life in various conditions.

Chemical Composition of Stainless Steel Alloys

Chromium is the main element of the stainless steel alloy. It gives the material unique properties. The chromium content can be up to 30%, providing protection against corrosion.

- Chromium: 12-17% in ferritic alloys

- Nickel: from 7% in austenitic alloys

- Additional elements: molybdenum, titanium

Classification of Stainless Steels

There are several main types of stainless steel. Each has its own characteristics:

| Type of Steel | Chromium Content | Features |

|---|---|---|

| Ferritic | 12-17% | Magnetic, low cost |

| Austenitic | 16-26% | High corrosion resistance |

| Martensitic | 11-13% | Increased hardness |

AISI 304 and AISI 316 are the most common grades. They are known for their high quality and wide application.

History of Stainless Steel

The history of stainless steel began with important scientific discoveries. These discoveries changed metallurgy forever. The invention of stainless steel was a true revolution in the world of materials science.

Invention and Development

Key milestones in the establishment of stainless steel include:

- 1797: Discovery of chromium by Louis Nicolas Vauquelin

- 1821: Pierre Berthier proved the unique properties of the alloy

- 1913: The first sample of stainless alloy with 12.8% chromium content

“Stainless steel is not just a metal, it is a technological marvel of its time,” say leading metallurgists.

Impact on Industry

The development of stainless steel changed production. Stainless steel became a breakthrough in machine engineering, the food industry, and medicine.

The metal has unique properties, such as corrosion resistance. This has allowed for the creation of new technological solutions. Alloys with more than 10.5% chromium have changed the perception of metalworking.

Types of Stainless Steel

The world of stainless steel alloys is very diverse. There are several main types, each with its own characteristics and applications.

Austenitic Stainless Steel

This is the most common type of stainless steel. It is very corrosion-resistant and well-suited for welding. Grade 304 contains 18% chromium and 8% nickel.

Ferritic Stainless Steel

Ferritic steel is very popular. It has magnetic properties and stands well against stress corrosion. Grade AISI 430 is the most well-known.

Martensitic Stainless Steel

Martensitic steel is very hard. It is well-suited for heat treatment. It contains about 12% chromium, which is used in tool manufacturing.

| Type of Steel | Chromium Content | Corrosion Resistance |

|---|---|---|

| Austenitic | 16-24% | High |

| Ferritic | 10.5-18% | Medium |

| Martensitic | 12-18% | Low |

Each type of stainless steel has its advantages. This allows for the selection of the material that best suits specific needs.

Main Properties of Stainless Steel

Stainless steel is a unique material. It has exceptional properties. This makes it very useful for many industries.

Corrosion Resistance

Corrosion resistance is a major advantage of stainless steel. It contains at least 10.5% chromium. This creates a protective layer on its surface.

This layer protects the metal from degradation. It provides long-lasting protection against corrosion.

- Resistance to aggressive environments

- Ability to withstand moisture

- Protection from chemical agents

Mechanical Properties

The mechanical properties of stainless steel are very diverse. It can have different levels of strength and plasticity.

| Type of Steel | Strength | Plasticity |

|---|---|---|

| Austenitic | High | High |

| Ferritic | Medium | Low |

| Martensitic | Very high | Low |

Heat Resistance

The heat resistance of stainless steel allows it to operate at high temperatures. Some grades can withstand temperatures up to 1100°C.

Stainless steel is an indispensable material. It is used in many fields, from food to aerospace.

Applications of Stainless Steel

Stainless steel is a unique material. It has a wide range of applications in various industries. Its properties make it indispensable in many areas of life.

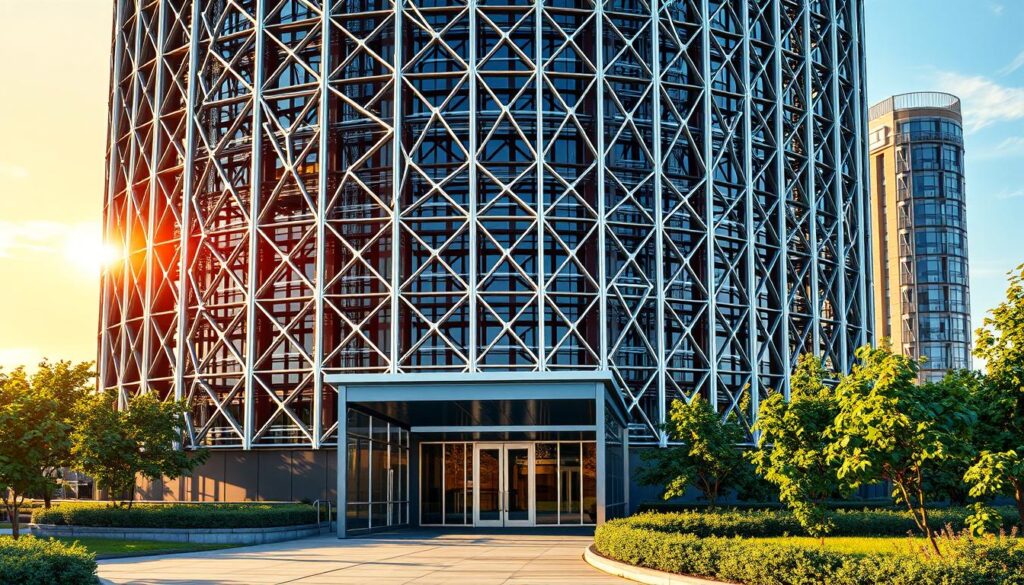

Use in Construction

In construction, stainless steel is very important. It helps create:

- Modern architectural elements

- Load-bearing structures

- Decorative railings

- Facade systems

Use in the Food Industry

In the food industry, stainless steel is very popular. Its properties help:

- Production equipment

- Kitchen equipment

- Containers for food storage

| Steel Class | Application | Features |

|---|---|---|

| AISI 304 | Food equipment | High corrosion resistance |

| AISI 316 | Aggressive environments | Additional resistance to chemical influences |

Use in the Medical Field

In medicine, stainless steel is very important. Its applications include the manufacture of:

- Surgical instruments

- Medical equipment

- Dental devices

- Implants

Stainless steel has a service life of over 50 years, without deforming or losing its properties.

Advantages of Stainless Steel

Stainless steel has unique properties that make it an ideal choice for many industries. It is very popular due to its advantages.

Durability

The main advantage of stainless steel is its long service life. It can last over 50 years without significant damage. This is due to the alloy of iron with chromium, which is highly resistant to corrosion.

- Service life up to 50 years

- High resistance to external damage

- Preservation of original properties for decades

Aesthetic Appearance

Stainless steel is very attractive in appearance. Its modern design and smooth surface are ideal for many architectural projects.

Ease of Maintenance

Another great advantage is the ease of maintenance. To keep the steel in perfect condition, it is enough to:

- Wipe the surface with a soft cloth

- Use mild detergents

- Avoid aggressive chemicals

Stainless steel is easily recyclable, which shows its environmental advantages. It remains practical and reliable for many applications.

Disadvantages of Stainless Steel

Stainless steel has many advantages, but also some disadvantages. It is important to be aware of these limitations when choosing a material for a project. Let’s consider the key properties of stainless steel that may be problematic.

Economic Features

One of the main disadvantages of stainless steel is its high price. It is more expensive than regular steel or concrete. This is due to:

- The complex manufacturing process

- The use of expensive alloying elements

- The high quality of the final product

The price depends on the grade and application of the steel. Construction industry specialists often compare the economic feasibility with long-term benefits.

Weight Characteristics

Another disadvantage is the weight of the material. Stainless steel is heavier than aluminum, plastic, or wood. This can complicate installation and transportation.

It is important to note that the high weight is compensated by the exceptional strength and durability of the material.

Despite these limitations, stainless steel is still very popular. Its unique properties make it desirable in many industries.

Production Process of Stainless Steel

The production of stainless steel is a complex process. It requires high precision and professional skills. The technical characteristics of the material depend on each stage of production.

Main Production Methods

Modern metallurgy uses three main methods for producing stainless steel:

- Martensitic technology

- Oxygen-converter technology

- Electric arc furnace technology

Stages of the Production Process

The production process of stainless steel includes several stages:

- Raw material preparation

- Melting of metals

- Alloying

- Heat treatment

- Shaping of the finished product

It is important that the chromium content is at least 10.5% for corrosion resistance.

Quality Control

At each stage of stainless steel production, thorough quality control is conducted. Modern technologies allow checking the chemical composition, mechanical properties, and structure of the metal.

The finished product undergoes multi-level testing. This ensures that it meets the highest standards.

Stainless Steel in Everyday Life

Stainless steel has become important in the modern home. It is used in many products that make our lives easier.

Kitchen Equipment

In the kitchen, stainless steel is very popular. Dishes, cutlery, kitchen appliances are made from it.

- Pots and pans

- Knives and kitchen utensils

- Household appliances

- Sinks and kitchen surfaces

Household Accessories

Stainless steel is used in many accessories. Its properties are very unique.

| Field of Use | Examples of Products |

|---|---|

| Plumbing | Faucets, shower systems |

| Furniture | Frames, decorative elements |

| Interior Details | Handrails, mirror frames |

Stainless steel is not just a material, it is a lifestyle of the modern person.

Stainless steel is very durable and hygienic. It does not react with food, is easy to clean, and maintains its appearance.

Environmental Aspects of Use

Stainless steel is a very clean material for production. It does not harm the environment. Its composition, which includes more than 10.5% chromium, provides corrosion resistance and safety for the environment.

Recycling stainless steel is very important for the environment. It is almost completely recyclable, which reduces the burden on natural resources. This means that stainless steel does not emit harmful substances and can be reused.

Stainless steel is very smooth, which prevents bacteria from growing. This further confirms its environmental advantages. Its long service life and the possibility of complete disposal make it a symbol of sustainable development.