Aluminum is a unique element, very important today. It is a lightweight silvery-white metal. It is widely used in various industries.

Aluminum ore is the main source of this metal. It constitutes 8.13% of the Earth’s crust among metals. More than 250 aluminum minerals are known, of which over 40% belong to aluminosilicates.

Aluminum has unique properties. It is very lightweight, has high electrical conductivity, and is resistant to corrosion. This makes it an indispensable material.

Key Findings

- Aluminum is the third most abundant element in the Earth’s crust

- Contains 14 neutrons and 13 protons

- Has wide industrial applications

- Is easily recyclable

- Characterized by low weight and high strength

Introduction to Aluminum

Aluminum is a unique metal. It has come a long way from being rare to being widely used. The history of aluminum shows how quickly science and technology have progressed.

What is Aluminum?

Aluminum is an active metal that is usually found in compounds. It is abundant in the earth and has special properties. The history of aluminum extraction began long before its industrial production.

- The most common aluminum compounds:

- Kaolinite (clay)

- Corundum

- Bauxite

- Nepheline

The History of Aluminum Discovery

In 1825, Hans Christian Ørsted obtained pure aluminum. At that time, it was so rare that its price was higher than that of gold and silver.

“Aluminum is a metal that changed the world of industry,” researchers say.

In the 19th century, aluminum was considered a luxury. Its properties, such as amphotericity, attracted scientists.

Physical Properties of Aluminum

Aluminum is a unique metal with interesting properties. It is very important in modern industry.

Lightness and Strength

Aluminum is very lightweight, with a density of 2.6989 g/cm³. This is very important for many industries:

- Aerospace

- Automotive industry

- Aerospace technology

Although it is very lightweight, aluminum is very strong. Annealed aluminum can withstand up to 50 MPa, while cold-rolled can withstand up to 115 MPa.

Thermal and Electrical Conductivity

Aluminum conducts heat very well, with a thermal conductivity of 237 W/(m·K). This is very useful for production:

- Electrical equipment

- Heat exchangers

- Cooling systems

The conductivity of aluminum is very high. At 20°C, its resistance is 2.6548·10−8 Ω·m.

Chemical Properties of Aluminum

Aluminum is a unique metal with interesting chemical properties. It is very active but highly resistant to external influences. This is due to its special chemical properties.

- Proton number 13

- Three electrons in the outer energy level

- Oxidation state +3 in all compounds

Corrosion Resistance

Aluminum has unique properties due to the instant formation of a thin film. This Al2O3 film protects the metal from further oxidation. This provides high corrosion resistance.

Reactivity of Aluminum

Aluminum can enter into various chemical reactions, even with the protective film:

- Reaction with oxygen: 4Al + 3O2 = 2Al2O3

- Interaction with water: 2Al + 6H2O = 2Al(OH)3 + 3H2↑

- Reaction with hydrochloric acid: 2Al + 6HCl = 2AlCl3 + H2↑

At high temperatures (1200-3000 °C), aluminum reduces metals from their oxides. This is very important in metallurgy.

Aluminum Production

Aluminum production is a complex process that requires a lot of energy. Aluminum ore does not exist in pure form in nature. It requires special processing.

Electrolysis Process

Electrolysis is the key method of aluminum production. The process occurs in special baths at a temperature of 950-960°C. Cryolite serves as a medium for converting alumina into pure metal.

Characteristics of the electrolysis process:

- Current: up to 150 kA

- Purity of aluminum: 99.7%

- Duration of the production cycle: 2-4 days

Main Sources of Bauxite

Deposits of aluminum ore are located all over the world. Australia, Brazil, Guinea, and Jamaica have the largest reserves. Each deposit has its own characteristics that affect the quality of the raw material.

Applications of Aluminum in Industry

Aluminum has made great strides in modern industry. The applications of aluminum cover many sectors due to its features.

This lightweight metal has changed many manufacturing processes. It is known for its strength, lightness, and corrosion resistance.

Aluminum in Construction

In construction, aluminum is very important. Aluminum structures weigh less than steel, which is very useful.

- Manufacturing building frames

- Production of window frames

- Facade finishing

- Manufacturing stairs

Use in the Automotive Industry

Automakers often use aluminum to reduce the weight of cars. Light aluminum alloys help save fuel.

| Industry | Application of Aluminum |

|---|---|

| Body | Outer cladding |

| Engine | Engine parts |

| Transmission | Light components |

Aluminum in Aviation

In aviation, aluminum is a primary material. It is used for aircraft bodies, engines, and other important parts.

Aluminum is an indispensable material in modern industry. It provides high efficiency and innovation in manufacturing processes.

Aluminum in Daily Life

Aluminum is widely used in our daily lives. It is lightweight, strong, and very practical. This makes it indispensable in many areas of everyday life.

In modern homes, there are many aluminum products. Their lightness and wear resistance make them ideal for many items.

Aluminum Kitchenware

Aluminum has become popular for kitchen utensils. It has many advantages:

- Even heat distribution during cooking

- Lightweight cookware

- High thermal conductivity

- Corrosion resistance

Household and Garden Products

Aluminum is used in many products:

| Category | Examples of Products |

|---|---|

| Kitchen | Pots, pans, baking trays |

| Garden Tools | Light ladders, folding furniture |

| Home Accessories | Frames, decorative elements, foil |

Aluminum products are very lightweight. This allows for the creation of functional items for everyday use.

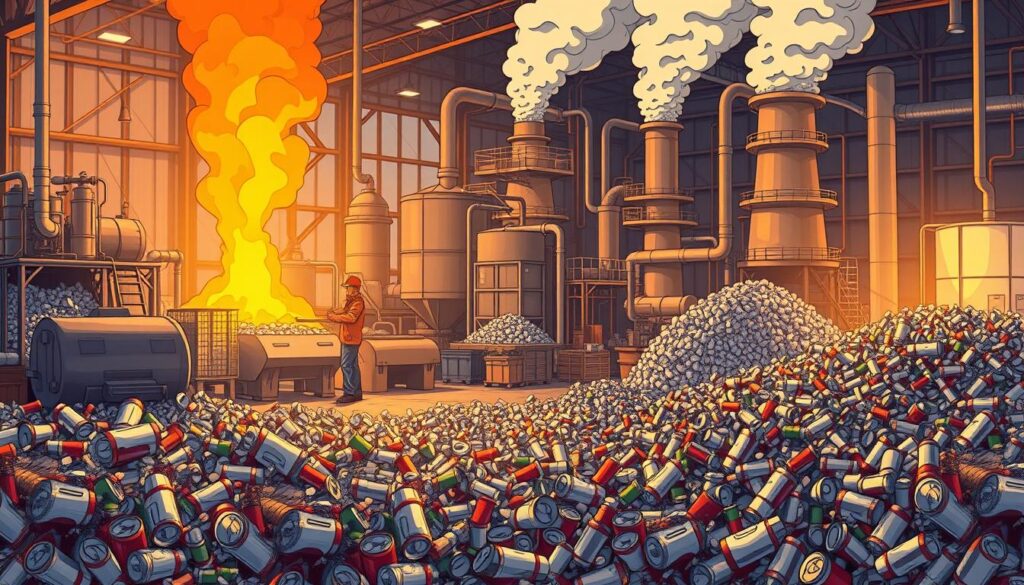

Aluminum Recycling

Aluminum is a unique metal that can be recycled many times without losing its properties. This is very important for modern industry. Aluminum recycling helps reduce harm to the environment.

- Consumes only 5% of the energy compared to primary production

- Significantly reduces the environmental impact of the aluminum industry

- Reduces the need for primary aluminum ore extraction

Environmental Aspects of Recycling

Aluminum recycling significantly reduces harm to the environment. Modern technologies convert waste with minimal resource expenditure. About 36% of aluminum in the USA comes from secondary raw materials.

Benefits of Aluminum Recycling

The main benefits include:

- Reduction of greenhouse gas emissions

- Conservation of natural resources

- Reduction of energy consumption by up to 95%

- Preservation of the environment

Innovative technologies improve aluminum recycling processes. This makes them more efficient and cleaner for the environment.

Aluminum in Technologies

Modern technologies cannot exist without aluminum alloys. This metal has revolutionized many industries. It has changed the world of electronics and manufacturing.

Aluminum alloys have features that make them ideal for the modern world. Their advantages include:

- Lightness and strength

- High electrical conductivity

- Corrosion resistance

- Ease of processing

Types of Aluminum Alloys

The most common aluminum alloys:

- Duralumin – contains copper, magnesium, and manganese

- Silumin – an aluminum-silicon alloy

- Alloys with zinc and magnesium

Use in Electronics

In the world of electronics, aluminum alloys are very important. They are used to manufacture:

- Smartphone casings

- Computer radiators

- Electronic components

- Printed circuit boards

Laser processing technologies for aluminum alloys create precise parts. They ensure high quality and minimal material deformation.

Aluminum and Health

Aluminum is a part of our lives. But its impact on the body raises many discussions.

In adult bodies, there is about 60 mg of aluminum. The WHO considers that up to 50 mg per day is safe.

Impact of Aluminum on the Body

Studies have shown health risks:

- Aluminum accumulates in the brain and lungs

- Toxic doses can change the body permanently

- High concentrations of the metal are associated with many diseases

Alternatives to Aluminum

Experts recommend:

- Using cookware made from other materials

- Monitoring aluminum consumption

- Choosing natural alternatives

| Source of Aluminum | Daily Norm | Potential Risk |

|---|---|---|

| Food Products | Up to 100 mg | Low |

| Cookware | Up to 50 mg | Medium |

| Deodorants | Up to 25% | High |

It is important to remember that only 2-4% of aluminum is absorbed. Proper use will help maintain health.

Modern Trends in the Aluminum Industry

The aluminum industry is preparing for major changes. Innovations and efforts to protect the environment will be key. Manufacturers are working on new technologies to reduce harm to the environment.

Innovations in Aluminum Processing

Technological progress has opened new avenues for the aluminum industry. Major achievements include:

- Development of 3D printing of aluminum products

- Implementation of nanotechnologies to improve the properties of the metal

- Creation of lighter and stronger aluminum alloys

Environmental Initiatives

Companies are trying to reduce their impact on the environment. Statistics show successes:

- Over 75% of aluminum continues to be reused

- Only 5% of energy is spent on recycling compared to primary production

- 70% of consumers are willing to pay more for eco-friendly products

By 2030, aluminum usage is expected to grow by 30%. The aluminum market in the Asia-Pacific region is projected to reach $125.91 billion by 2025.

Advantages and Disadvantages of Using Aluminum

Aluminum is a unique metal widely used in industry. Let’s look at its advantages and disadvantages.

Key Advantages

- Extremely lightweight metal with a specific weight of 2.69808 g/cm³

- High corrosion resistance

- Excellent electrical and thermal conductivity

- Ease of processing and shaping

Aluminum is very effective in many sectors:

| Industry | Share of Use |

|---|---|

| Construction | 25% |

| Automotive | 15% |

| Aviation | 20% |

| Electrical Engineering | 10% |

Significant Disadvantages

- High energy intensity of production

- Susceptibility to damage and scratches

- Limited mechanical strength at high temperatures

- Possibility of oxidation with prolonged contact with aggressive environments

Although aluminum has disadvantages, its use is increasing. Choosing the right alloys and processing technologies helps reduce the drawbacks.

The Future of Aluminum

The global aluminum trade market is rapidly growing. This is due to its unique properties. Transparent aluminum is becoming a true technological revolution.

It offers extraordinary strength and thermal resistance up to 2100 °C. This opens new horizons for various industries.

Innovations in aluminum production and trade are aimed at expanding its applications. From aerospace to medicine, transparent aluminum is becoming a key material.

It is used to create protective screens, fairings, and high-tech structures.

The future of the metal is linked to environmental initiatives and sustainable development. It is expected that aluminum recycling will reduce energy costs by 95%.

The growth of urbanization will lead to an increased demand for this unique metal in developing countries.