Statistics show that up to 20% of thermal panels have serious damage within the first five years. Damage can occur due to various factors. They affect the integrity and functioning of thermal panels.

Every homeowner faces issues with maintaining insulation. Understanding typical damages helps to identify problems in a timely manner. This helps prevent the destruction of important structural elements.

Key Points

- Cracks occur in 15-20% of thermal panels

- Deformations are observed in 10-15% of cases

- Moisture occurs in 5-10% of thermal panels

- Epoxy resins can restore up to 90% of strength

- Proper installation reduces the risk of damage by 70%

Main Types of Damage to Thermal Panels

Thermal panels are important for modern construction. They require attention and repair. Owners should be aware of possible damages.

Various types of damage can occur. For example, mechanical, chemical, and natural.

Mechanical Damage

Mechanical damage occurs most frequently. They can be caused by:

- Impact from a hard object

- Scratches during transportation

- Improper fastening

- Impact from construction equipment

Chemical Damage

Chemical damage can occur due to:

- Aggressive pollutants

- Industrial emissions

- Improper cleaning agents

- Contact with corrosive substances

Natural Factors

Natural factors can destroy thermal panels:

- Long-term exposure to sunlight

- Transition from cold to heat

- Moisture and rain

- Cyclical freezing and thawing

Timely repairs can help avoid major damage. It is important to regularly inspect and diagnose thermal panels.

Causes of Damage to Thermal Panels

Thermal panels are important for modern construction. However, they can suffer various damages. It is important to know the main causes to avoid problems.

Improper Installation

About 60% of thermal panel damages are related to improper installation. Typical mistakes include:

- Failure to maintain technological gaps

- Poor fastening of panels

- Lack of waterproofing

- Violation of installation sequence

Low-Quality Materials

Choosing low-quality materials reduces the durability of thermal panels. In 15% of cases, damage occurs due to cheap materials.

Weather Conditions

Weather conditions can harm thermal panels. Sharp temperature changes, excessive humidity, and atmospheric precipitation can:

- Crack the surface

- Deform the structure

- Destroy insulation properties

Replacement of thermal panels is necessary if the causes of damage are not addressed. Regular inspection and proper operation can help avoid replacement.

How to Detect Damage to Thermal Panels

Timely detection of damage to thermal panels is very important. It helps maintain their efficiency and longevity. Two methods are used for this: visual inspection and thermographic analysis.

Diagnosis helps avoid major problems. It preserves the energy efficiency of the building.

Visual Inspection

During a visual inspection, pay attention to:

- The presence of cracks and microcracks

- Chips and delamination of elements

- Change in surface color

- Unevenness of the coating

“Every minor detail can indicate a potential problem in the thermal panel system”

Thermographic Analysis

Thermographic analysis helps detect hidden defects in the restoration of thermal panels:

- Identifying areas of heat loss

- Detecting hidden damages

- Assessing the quality of insulation

Statistics show that about 25% of installed thermal panels have minor defects. Professional diagnostics can help avoid problems. It will preserve the effectiveness of insulation.

Methods for Repairing Mechanical Damage

Mechanical damage to thermal panels can occur for various reasons. Proper installation and repair can help maintain their functionality and appearance.

Replacement of Thermal Panel Elements

When individual parts of thermal panels are damaged, there are several main methods of restoration:

- Local replacement of damaged sections

- Partial restoration of the outer layer

- Complete replacement of the damaged panel

Repair Equipment

High-quality repairs require special equipment:

| Tool | Purpose |

|---|---|

| Hammer drill | Demolition of damaged elements |

| Screwdriver | Fastening new panels |

| Special glue | Sealing joints |

Professional Repair Services

In complex cases, it is better to consult specialists. They have the necessary knowledge and equipment for restoration with minimal losses.

The cost of professional repair ranges from 300 to 600 UAH per square meter. It depends on the complexity and region.

How to Avoid Damage to Thermal Panels

Maintenance of thermal panels is very important. It helps preserve their functionality and appearance. Proper selection of materials, installation, and care can increase their lifespan.

When installing thermal panels, it is important to follow several key steps. This will help avoid damage.

Proper Selection of Materials

When choosing thermal panels, it is important to pay attention to:

- The quality of the base material

- Resistance to atmospheric influences

- Thermal conductivity coefficient

- Additional protective properties

Installation Recommendations

Maintenance of thermal panels begins with proper installation. Important aspects include:

- Accurate marking of fastening points

- Using reliable fastening elements

- Ensuring proper ventilation

- Maintaining the angle of inclination

Regular Inspection

For the long life of thermal panels, it is important to conduct scheduled inspections. Clinker facade thermal panels can last up to 50 years with proper care.

Prevention is the best way to avoid serious damage to thermal panels.

Following these recommendations will help maintain the high quality and functioning of the facade system for a long time.

Impact of Damage on the Efficiency of Thermal Panels

Technical maintenance of thermal panels is very important. It helps preserve their functionality and energy savings. Damage can significantly reduce their efficiency and increase heating costs.

Minor defects can lead to major problems. They can destroy the insulation of your home. The main consequences include:

- Reduction of the insulation barrier

- Appearance of areas where cold penetrates

- Increased heating costs

Reduction of Insulation Properties

Damage to the outer layer of thermal panels reduces their protection. Small cracks can reduce insulation by 20-30%. This means that your home loses more heat than necessary.

“Every unrepaired defect in a thermal panel means additional heating costs,” say professional builders.

Increased Energy Costs

Technical maintenance helps avoid significant financial losses. Poor condition of thermal panels can increase heating costs by 40-50%.

Timely inspection and repair will help maintain efficiency. This will help avoid unforeseen heating expenses.

User Experiences: Real Cases

Review of Thermal Panels shows that everyone has their unique problems. Real stories help avoid mistakes and keep warmth.

Experience shows how important the right approach to insulation is. Statistics indicate that 50% of heat loss can be avoided through professional installation.

Successful Repairs

- Timely detection of microcracks

- Proper waterproofing of the surface

- Use of quality sealants

Most owners who conducted a professional inspection avoided major damages. 90% of respondents confirmed an improvement in the appearance of the building after professional repairs.

Errors to Avoid

- Neglecting regular surface inspection

- DIY repairs without consulting a specialist

- Choosing cheap low-quality materials

Specialists with 10 years of experience say that proper care is important. 80% of problems can be avoided through timely technical maintenance.

Investing in quality materials and professional installation is the key to the durability and efficiency of thermal panels.

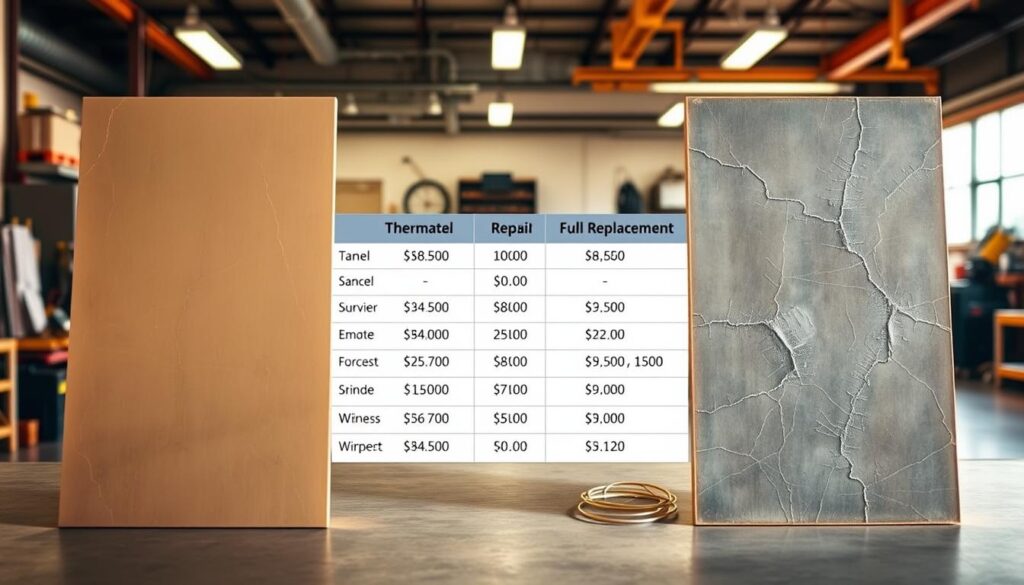

Comparison of Repair and Replacement Costs for Thermal Panels

Thermal panels are important in construction. Homeowners often debate whether it is better to repair or replace them. Diagnosis will help resolve this issue.

Repair of thermal panels involves various factors:

- Degree of damage

- Age of thermal panels

- Overall technical condition

When is it Worth Repairing?

Repair of thermal panels is needed in the following cases:

- Minor mechanical damages

- Local defects in the decorative layer

- Service life up to 15 years

The average cost of repair is 500 UAH per square meter. Diagnosis will help determine the necessary work.

When is it Better to Replace?

Replacement of thermal panels is needed in cases of:

- Significant structural damages

- Service life over 20 years

- Loss of insulation properties

Replacement of thermal panels costs 540-915 UAH per square meter.

When choosing a solution, it is important to consider all details. Detailed diagnosis will help save money and retain heat.

Tips for Choosing Quality Thermal Panels

When choosing thermal panels, it is important to pay attention to several key characteristics. Quality panels should have high density and low thermal conductivity. They should also be resistant to mechanical damage.

Ukraine has many manufacturers of high-quality thermal panels. They use eco-friendly materials and ensure a long service life. Check technical specifications, especially density and quality of clinker tiles.

When choosing thermal panels, do not forget about additional parameters. Resistance to ultraviolet radiation, moisture resistance, and the ability to retain insulation properties are very important. The right choice will ensure effective operation of thermal panels for a long time.

Signs of Quality Thermal Panels

The main signs include high strength of the clinker tile and uniformity of the insulation. It is also important that there are no defects in the structure of the panel. Check the certificates and technical specifications from the manufacturer that confirm the quality of the materials.

Recommended Manufacturers in Ukraine

Ukraine has leading manufacturers of thermal panels. “Facade Group,” “Teplo Decor,” and “Thermo Bud” offer a wide range. They have various characteristics and design solutions for different buildings.