Smooth reinforcement is very important in modern construction. It helps strengthen concrete structures. Metal rods of this type are widely used in various industries.

These building materials have unique properties. They make structures reliable and durable. Smooth reinforcement increases the mechanical stability of structures.

Key Findings

- Smooth reinforcement has a cross-section from 6 to 40 mm

- Used in various construction sectors

- Provides high strength of concrete structures

- Manufactured from high-quality steel

- Has standardized parameters and characteristics

What is smooth reinforcement?

Smooth reinforcement is a key element of reinforced steel. It is very important for strengthening concrete structures. This ensures their reliability.

- Diameter range from 6 to 40 mm

- Smooth surface without ribs and notches

- Manufactured from steel grades St3sp, St3ps

Definition of reinforcement

Smooth reinforcement is a metal rod with a round cross-section. It is designed to strengthen concrete structures. Reinforced steel provides additional strength and stability.

Main types of smooth reinforcement

Among the main types of smooth reinforcement are:

- Class A1 – standard reinforcement

- Class A2 – high strength

- Class A3 – for critical structures

Smooth reinforcement has a wide application in modern construction due to its unique properties.

When choosing smooth reinforcement, it is important to consider the specifics of the project and the required loads. The right choice will ensure the reliability and durability of building structures.

Main characteristics of smooth reinforcement

Smooth reinforcement is important in construction. It has special properties and technical parameters. Metal rods of this type provide strength and reliability to buildings.

Mechanical properties of smooth reinforcement

The mechanical characteristics of smooth reinforcement are important for construction. They include:

- Yield strength: not less than 240 MPa

- Tensile strength: not less than 370 MPa

- Relative elongation: over 25%

Diameter and length of metal rods

Smooth reinforcement is manufactured in various sizes. This allows it to be used in different construction projects:

| Reinforcement class | Diameter (mm) | Length (m) |

|---|---|---|

| A1 | 6-40 | 6-12 |

| A2 | 40-80 | 6-12 |

| A3 | 6-40 | 6-12 |

The choice of diameter and length of smooth reinforcement depends on the project. It is also important to consider the expected loads on the structure.

Advantages of using smooth reinforcement

Smooth reinforcement is very important for strengthening concrete. It has many advantages that make it indispensable in construction.

High strength

The main advantage of smooth reinforcement is its high strength. Class A1 products can withstand up to 373 N/sq.mm. This ensures the reliability of buildings.

- Yield strength is 240-300 MPa

- Relative elongation in bending – 25%

- Bending tests are conducted at 180 degrees

Ease of transportation

Smooth reinforcement is easy to transport. It can be transported up to 15 tons. This greatly simplifies the delivery of materials.

| Reinforcement class | Profile cross-section (mm) | Storage temperature |

|---|---|---|

| A1 | 6-40 | 18-20°C |

| A2 | 40-80 | 18-20°C |

| A3 | 6-40 | 18-20°C |

Smooth reinforcement is important for construction. It provides reliability and durability to structures.

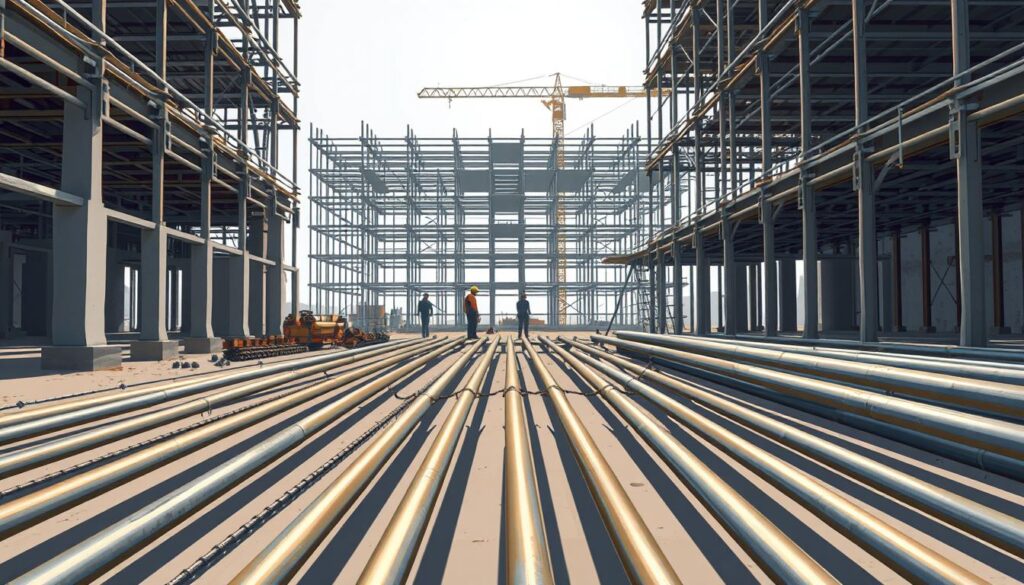

Application of smooth reinforcement in construction

Smooth reinforcement is very important in construction. It makes reinforced concrete structures strong and reliable. It is used in many buildings, from houses to large factories.

Foundations of structures: a reliable base

In the construction of foundations, smooth reinforcement of class A1 is very important. It:

- Increases the strength of concrete

- Resistant to heavy loads

- Evenly distributes weight

A properly reinforced foundation is the key to the longevity of the building.

Reinforced concrete structures: a variety of applications

Concrete structures with smooth reinforcement A1 are used in many projects. Statistics show that about 90% of buildings in Ukraine use smooth reinforcement.

It can be seen in many places:

- Load-bearing walls

- Columns

- Slabs

- Bridges

- Industrial buildings

Smooth reinforcement has special properties. Its diameter ranges from 6 to 40 mm. It withstands heavy loads.

Main methods of manufacturing smooth reinforcement

The production of smooth reinforcement is a complex process. It requires high precision and adherence to standards. Special solutions ensure its reliability and quality.

- Preparation of raw materials

- Melting of metal

- Hot rolling

- Cooling and shaping

- Quality control

Production process

Smooth reinforcement is produced by hot rolling. The technology involves heating the metal to high temperatures and rolling it through rollers.

“The quality of smooth reinforcement depends on the accuracy of adherence to all technological modes,” say experts in the metallurgical industry.

Quality standards

Strict standards are important in the production of smooth reinforcement. Key requirements include:

- Tensile strength of not less than 373 N/sq.mm

- Relative elongation in bending 25%

- Control of the chemical composition of the metal

- Verification of geometric parameters

Professional manufacturing of reinforcement products ensures high reliability. This is important for the construction industry.

Smooth reinforcement vs. ribbed reinforcement

In the world of construction, smooth and ribbed reinforcement are very important. They help create strong concrete structures. Each type has its own characteristics that help solve construction tasks.

Comparative analysis of characteristics

Let’s see how these two types of reinforcement differ:

- Smooth reinforcement has a diameter from 6 to 40 mm

- Ribbed reinforcement has a diameter from 5 to 60 mm

- Smooth reinforcement has lower adhesion to concrete

- Ribbed reinforcement adheres better to concrete

Criteria for choosing reinforcement

When choosing reinforcement for concrete structures, it is important to consider several factors:

- Load level on the structure

- Operating conditions

- Economic possibilities of the project

Ribbed reinforcement makes concrete 10 times stronger compared to ordinary reinforcement.

Smooth reinforcement is ideal for lightweight structures. It is also well-suited for auxiliary elements. Ribbed reinforcement is better suited for critical building structures, foundations, and structures with high loads.

Use of smooth reinforcement in various industries

Smooth reinforcement is very important in construction. It has unique properties. This allows it to be used in many industries.

Smooth reinforcement is very important for the construction of reinforced concrete structures. Let’s talk about its applications.

Industrial construction

In industry, smooth reinforcement is very important. It is used for the construction of:

- Factory buildings

- Warehouse complexes

- Chemical production facilities

- Engineering infrastructure facilities

Smooth reinforcement withstands aggressive environments well. This is very important in the chemical industry.

Residential construction

In residential construction, smooth reinforcement is used for the construction of:

- High-rise buildings

- Private houses

- Social facilities

- Community buildings

Ukraine has various diameters of smooth reinforcement A240. They range from 5.5 to 45 mm. This allows for very flexible use.

| Industry | Usage features |

|---|---|

| Industry | Corrosion resistance, high strength |

| Residential construction | Reliability, durability of structures |

Smooth reinforcement is a key element of modern construction. It provides strength and reliability to reinforced concrete structures.

Environmental aspects of using smooth reinforcement

Smooth reinforcement is important for construction. It impacts the environment. Modern technologies strive to be more environmentally friendly and economical.

Impact on the environment

The production of smooth reinforcement has its ecological footprint. The main issues include:

- Carbon dioxide emissions during production

- Consumption of natural resources

- High energy required for production

Research shows that at a temperature of 400°C, the carbon content in materials is about 77.3%. This indicates opportunities for improving production.

Recycling and disposal

Today, there are several ways to dispose of smooth reinforcement:

- Reuse of scrap metal

- Melting down reinforcement

- Minimizing production waste

The thermal conductivity coefficient of special coatings in the temperature range of 600-1200°C is 0.1-0.2 W/m·K. This helps to recycle materials more efficiently.

The environmental friendliness of smooth reinforcement is an important direction for the development of modern construction production.

Recommendations for choosing smooth reinforcement

Choosing high-quality smooth reinforcement is very important. It affects the strength of building structures. The right choice ensures a long service life.

When choosing smooth reinforcement, it is important to pay attention to several key points:

- Absence of visible defects on the surface

- Compliance with state standards

- Availability of certification

- Diameter of reinforcement (from 6 to 40 mm)

Quality criteria for selection

It is important to check smooth reinforcement for:

- Minor rust

- Signs of air bubbles

- Absence of deep cracks

Where to buy reliable reinforcement

It is recommended to buy smooth reinforcement at:

- Specialized construction stores

- Metal bases

- Direct supplies from manufacturers

- Verified online platforms

Remember: the quality of reinforcement determines the strength of the entire structure!

Price categories of smooth reinforcement

The price of smooth reinforcement depends on many factors. The diameter, class, and grade of reinforcement products determine its cost. These are key elements in the construction industry.

Several factors influence the price of smooth reinforcement. These include the quality of the metal, production technology, and transportation costs. The market conditions for construction materials are also important.

Orders and suppliers also affect the price. Professional builders are advised to compare prices from different manufacturers. It is important to consider not only the price but also the technical specifications and the reputation of the supplier.