Shut-off valves are very important in many systems. They regulate the flow of water and other liquids in buildings and industry. This helps keep the system in a stable state.

The best choice and installation of valves are very important. Each element has its purpose. This affects the operation of the system.

In this article, we will talk about shut-off valves. You will learn about their types, how to choose and install them. This will help specialists make the right choice.

Key Points

- Shut-off valves provide complete flow control

- There is a wide range of types and modifications of valves

- The right choice affects the reliability of the system

- The material of manufacture is critically important

- Technical characteristics determine the area of application

What is a shut-off valve?

Shut-off valves are an important element of many technical systems. They help control the movement of liquids and gases. They also provide flow regulation and enhance safety.

The function of shut-off valves is to completely or partially close channels. This helps effectively manage the movement of various media.

Definition of shut-off valves

Shut-off valves are designed for:

- Complete closure of flow in pipelines

- Regulating the intensity of the movement of liquids and gases

- Ensuring the tightness of systems

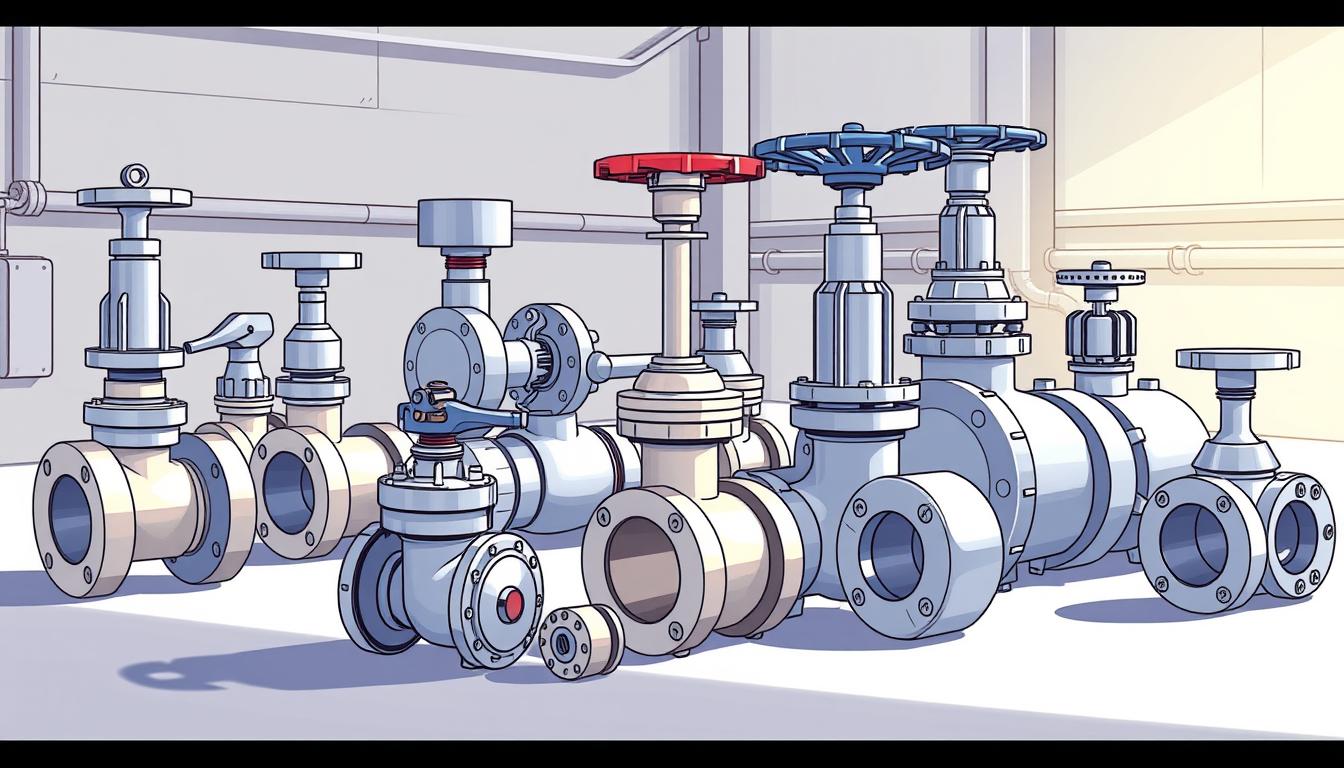

Main types of shut-off valves

Among the most common types are:

- Valves – for precise flow regulation

- Gates – provide reliable closure of pipelines

- Controls – allow smooth control of the movement of media

Each type has its features. This makes them indispensable in various industries.

The right choice of shut-off valves is critically important for the effective operation of any pipeline system.

The importance of choosing shut-off valves

The right choice of shut-off valves is very important. It ensures the efficiency and reliability of engineering systems. The better the quality of ball valves and throttle plates, the better the water supply, heating, and other communications work.

A professional approach to choosing valves helps achieve important results:

- Ensuring complete tightness of the system

- Rational use of resources

- Minimizing maintenance costs

- Increasing operational reliability

How the choice of valves affects water supply systems

In modern networks, ball valves and throttle plates are very important. Incorrect choice can lead to major problems: from loss of efficiency to system failure.

Ways to determine the quality of materials

When choosing valves, it is important to pay attention to the following characteristics:

- Manufacturer certification

- Body material

- Operating temperature range

- Pressure in the system

- Operating conditions

Quality shut-off valves are a guarantee of reliable operation of the water supply system.

Main criteria for choosing shut-off valves

Choosing the right shut-off valves is very important. It affects the operation of engineering systems. Proper selection ensures the reliability and efficiency of pipelines.

- Pipeline diameter

- Temperature regime

- Type of working medium

- Pressure in the system

Technical characteristics of shut-off valves

Technical characteristics show whether the valves are suitable for specific conditions. It is important to pay attention to:

- Body material

- Sealing class

- Flow cross-section

- Working pressure

“The quality of shut-off valves is the key to the reliability of the entire system”

Cost and budget constraints

When choosing valves, it is important to find a balance between price and quality. Cheap valves can often break, leading to additional costs.

The average price depends on:

- Material of manufacture

- Manufacturer

- Technical characteristics

Investing in quality valves is a smart decision for long-term operation.

Types of shut-off valves

Pipeline valves are very important for the operation of engineering systems. They come in many types to solve technical tasks in various fields.

Filters and shut-off valves are divided into several main groups. Each group has its features and purposes.

Ball valves

Ball valves are very popular. Their design allows for quick stopping of the flow of liquid or gas. They have several key features:

- Temperature regime up to 100 degrees

- High tightness

- Ease of operation

Valves

Valves help regulate flow in systems. They are divided into several types:

| Type of valve | Features |

|---|---|

| Check valve | Prevents reverse flow of the medium |

| Regulating valve | Allows precise flow control |

Gates

Gates are used for complete closure of flow. Their characteristics:

- Made of steel

- Suitable for various media

- Provide airtight closure

The choice of the type of shut-off valve depends on the system, medium, and technical requirements.

Advantages of using modern shut-off valves

Modern shut-off valves have made significant strides in technical solutions. They have unique properties that are very important in various fields.

Let’s talk about the advantages of modern shut-off valves. They are a key element for reliable systems:

Durability and reliability

Modern shut-off valves are made from high-quality materials. This ensures their long service life:

- Use of stainless steel

- Implementation of special polymers

- Resistance to corrosion and mechanical damage

Energy efficiency of valves

Innovative valves and other types of valves reduce energy costs:

- Minimal losses during the transportation of liquids

- Precise flow control

- Reduction of operating costs

Choosing modern shut-off valves means choosing reliable equipment. It will last long and ensure the efficiency of the system.

Installation of shut-off valves

The installation of shut-off valves is very important for the operation of pipeline systems. The quality of the installation of gates and valves affects the operation of engineering infrastructure.

Preparation for installation

Before installation, it is necessary to prepare the work area and tools well. The main preparation actions include:

- Checking the completeness of the valves

- Inspecting the technical condition of gates and valves

- Preparing tools

- Ensuring safety

Main stages of installation

The installation of valves and gates includes several stages:

- Cleaning the pipes

- Checking tightness

- Fixing the valves

- Installing seals

| Type of connection | Installation complexity | Prevalence |

|---|---|---|

| Threaded connection | Low | 40% |

| Flanged connection | Medium | 50% |

| Welded connection | High | 60% |

During installation, it is important to be precise and adhere to technical requirements. Quality installation of gates and valves ensures uninterrupted operation.

Features of installation in different systems

Shut-off valves are very important for the operation of engineering systems. Proper installation ensures their reliability and efficiency. This applies to various fields.

The installation of valves requires attention and adherence to specific requirements. This depends on the type of system.

Installation in water supply systems

When installing in water supply systems, it is important to:

- Check the tightness of connections

- Consider the diameter of the pipeline

- Use quality seals

Features of installation in heating systems

In heating systems, it is important to:

- Precise installation for flow regulation

- Consider temperature loads

- Protect against corrosion

Installation in gas supply

Gas supply has the strictest requirements:

| Requirement | Description |

|---|---|

| Tightness | 100% tightness of connections |

| Material | Special corrosion-resistant alloys |

| Testing | Mandatory pressure testing |

Professional installation ensures safety and long-term operation of engineering communications.

Maintenance tips for shut-off valves

Proper maintenance of shut-off valves is very important. It ensures their long and reliable operation. Regulating valves and check valves require special attention.

- Check the gate monthly

- Lubricate the stem every 1-2 months

- Monitor the condition of the packing seal

- Check the tightness of connections

Regular maintenance

For effective operation of regulating valves, it is important to adhere to a preventive schedule. The main steps include:

- Checking the integrity of the body

- Cleaning from scale and dirt

- Diagnosing possible damage

- Lubricating moving parts

Replacing old elements

When operating check valves, it is important to timely detect signs of wear. Critical indicators include:

- Appearance of corrosion on metal parts

- Loss of tightness

- Difficulty in maneuvering

- Deformation of sealing elements

Timely diagnosis and replacement of worn parts will help avoid accidents. This will extend the service life of shut-off valves.

Common mistakes when choosing shut-off valves

Choosing valves may seem simple, but in reality, there are many issues. They can lead to significant delays in the system.

During the installation of filters and valves, mistakes often occur. They can cost a lot of money and nerves.

Incorrect calculation of parameters

The biggest problem is the incorrect choice of technical characteristics. This can lead to:

- Reduced system efficiency

- Premature equipment failure

- Increased operating costs

When choosing valves, it is important to consider:

- Pipe diameter

- Working pressure

- Temperature regime

Ignoring quality certificates

Buying uncertified shut-off valves can have serious consequences. Poor quality materials can:

- Create emergency situations

- Cause premature wear of equipment

- Compromise the tightness of systems

The temperature regimes of different sealing materials vary from -40°C to +250°C. The choice should be as thoughtful as possible.

Recommendations for purchasing shut-off valves

Buying quality shut-off valves is very important. They help ensure the reliable operation of systems. The right choice prevents problems with water, heating, and other systems.

Where to buy shut-off valves in Ukraine

Ukraine has a wide selection of shut-off valves from various manufacturers. You can find them in:

- Specialized plumbing stores

- Online platforms

- Construction hypermarkets

- Professional trading platforms

Statistics show that 80% of the range of valves consists of shut-off valves. This indicates their importance.

What to pay attention to when buying

When choosing shut-off valves, it is important to pay attention to several key points:

- Quality certificates

- Manufacturer reputation

- Warranty conditions

- Technical characteristics

| Brand | Features | Average price |

|---|---|---|

| Albertoni | High quality | from 500 UAH |

| Bianchi | Reliability | from 450 UAH |

| Caleffi | Wide range | from 400 UAH |

Prices for shut-off valves start from 11.35 UAH. It is important to choose products that meet your requirements and budget.

Problems and solutions during operation

The operation of water supply and heating systems can be associated with problems. This is especially true for shut-off valves. Proper maintenance of valves and gates helps avoid many problems.

Typical valve malfunctions

During operation, the following problems may arise:

- Loss of tightness

- Corrosion of metal elements

- Mechanical damage

- Wear of sealing elements

How to avoid breakdowns in the system

To avoid problems, it is necessary to follow several recommendations:

- Regularly perform maintenance

- Conduct preventive inspections

- Timely replace worn elements

- Monitor pressure in the system

Statistics show that about 70% of the water supply network needs updating. Of these, 20-30% require immediate replacement. This emphasizes the importance of paying attention to the condition of valves.

If problems are detected in valves or gates, it is necessary to immediately contact specialists. They will be able to diagnose and fix the problems.

Trends in the shut-off valve market

The modern market for shut-off valves in Ukraine is rapidly developing. Manufacturers are creating new solutions to enhance the reliability of systems. Designing modern engineering networks requires high-quality valves.

Innovations in intelligent control systems are gaining popularity. Now valves have built-in sensors for monitoring. This helps quickly detect problems and increases reliability.

The market is also focusing on environmentally friendly solutions. Ukrainian companies are working on materials and technologies that meet modern standards. Customers desire products with a long service life and low maintenance costs.