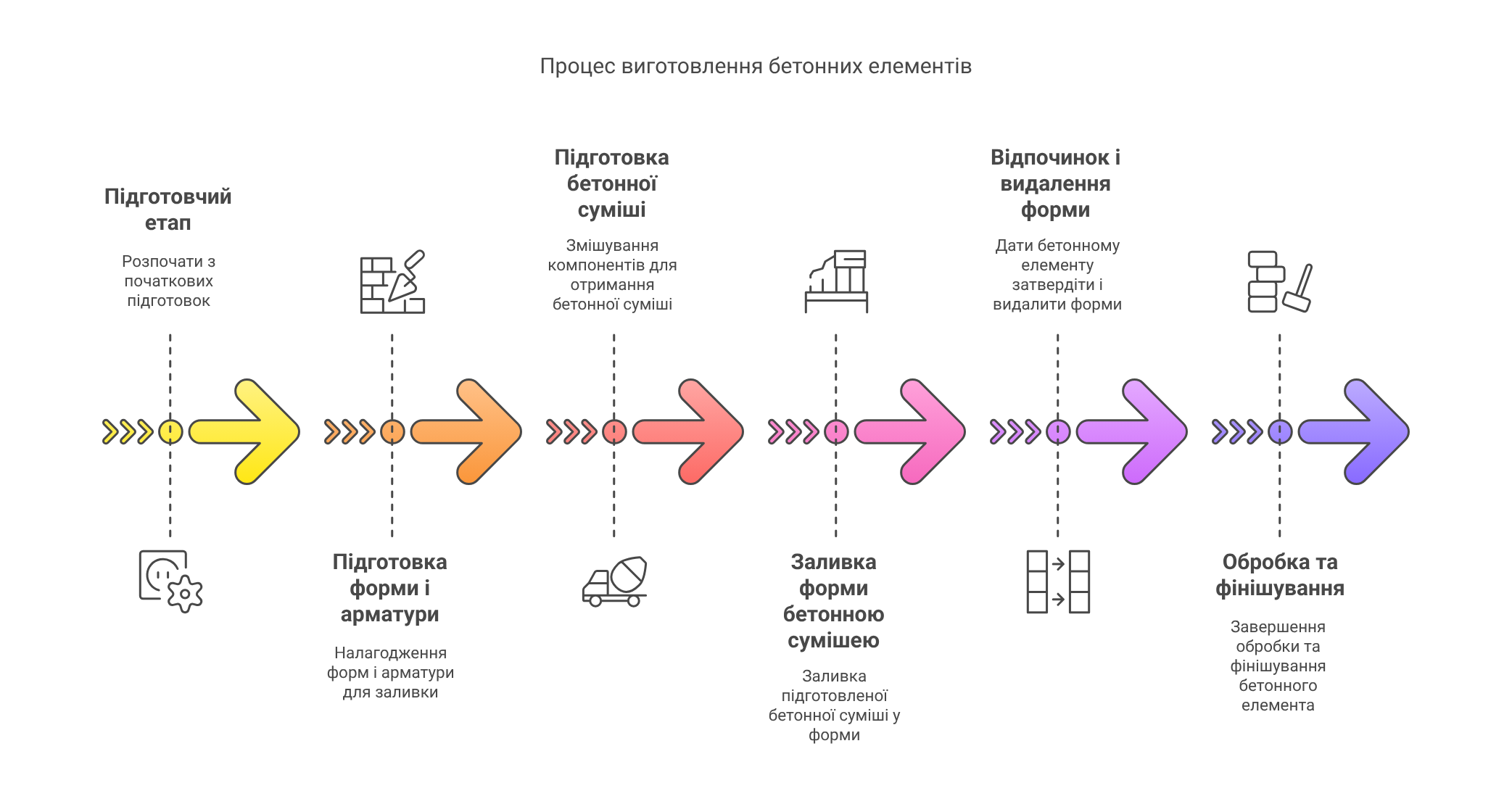

Technological Process of Paving Tile Production

The technological process of paving tile production is a complex engineering activity that includes several stages. Adhering to the correct production process is important to ensure the quality and durability of the paving tiles.

1. Preparatory Stage

At the beginning of the paving tile production, it is necessary to carry out preparatory work. This includes selecting the material for the tiles and delivering it to the production site. The choice of material depends on many factors, such as durability, frost resistance, and aesthetic properties. The delivery of the material should be carried out considering its weight and dimensions.

2. Preparation of Mold and Reinforcement

After the preparatory stage, we move on to the preparation of the mold and reinforcement. The mold is used to create the finished tiles. It must be thoroughly washed and lubricated to prevent the concrete from sticking. The reinforcement is used to strengthen the tiles and prevent cracking. It should be placed in the mold considering the necessary arrangement and connection of the elements.

3. Preparation of Concrete Mixture

In the third stage of production, it is necessary to prepare the concrete mixture. For this, the composition and ratio of the concrete components: cement, sand, gravel, water, and additives are determined in advance. All components must be well sifted and mixed to ensure the uniformity and quality of the concrete mixture.

4. Filling the Mold with Concrete Mixture

After preparing the concrete mixture, we proceed to fill the mold. The concrete mixture is evenly distributed throughout the mold, and the reinforcement must be completely covered. After filling the mold, it is necessary to provide vibration to eliminate air pockets and increase the density of the concrete.

5. Rest and Removal of Mold

After filling the mold with the concrete mixture, it is necessary to give the tiles time to rest and gain strength. This stage takes place in special conditions that ensure optimal temperature and humidity. After the designated time, the mold can be removed, and the tiles are ready for the next stages of processing and use.

6. Processing and Finishing

The final stage of the technological process of paving tile production is processing and finishing. This stage includes cleaning the surface of the tiles from irregularities and removing excess materials. Additional operations, such as applying paint or protective coating, may also be performed.

The technological process of paving tile production consists of several stages, from preparing materials to finishing the finished tiles. By properly executing each stage, high quality and durability of the paving tiles can be achieved. It is important to adhere to the technological process and consider all parameters to obtain a finished product that meets the requirements and satisfies consumer needs.

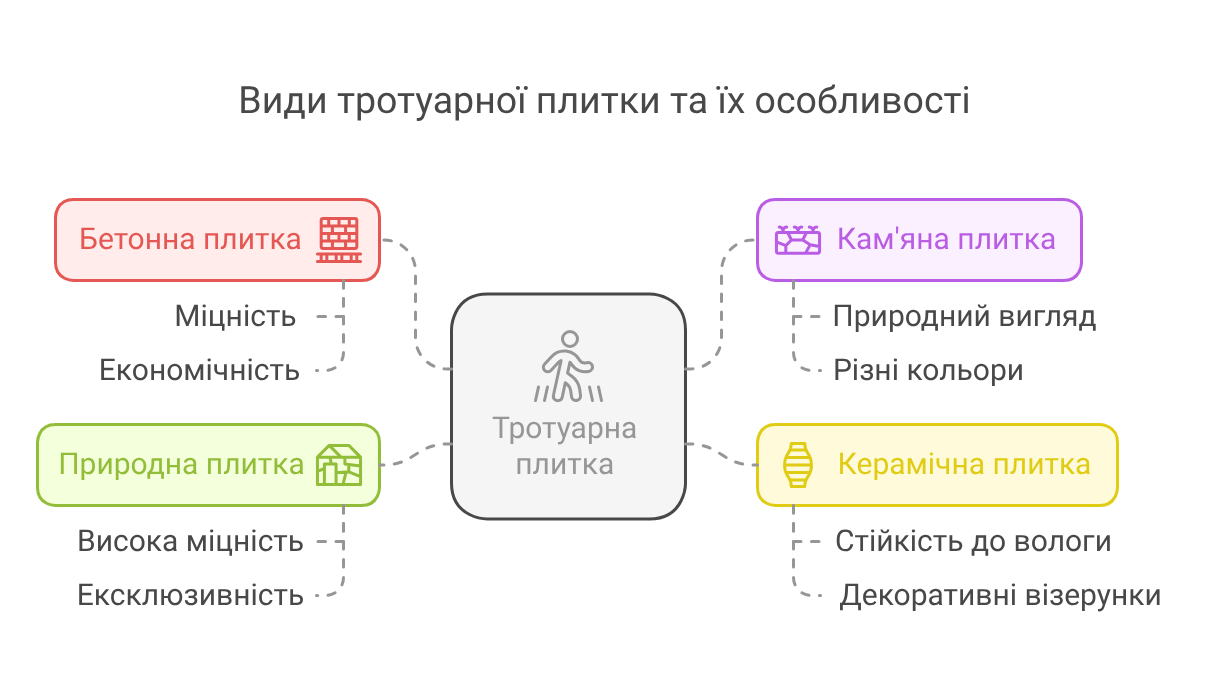

Types and Variations of Paving Tiles

The smart organization of space around houses and other buildings is an important component of the modern urban environment. One of the key elements of such organization is paving tiles, which serve not only as decorative finishing but also provide comfortable and safe mobility for pedestrians.

Paving tiles are materials for arranging sidewalks, platforms, alleys, and other pedestrian areas. They are made from various materials, including concrete, stone, ceramics, and natural stone. Each of these materials has its advantages and specific features of use.

Concrete paving tiles are one of the most common types of tiles. They are produced by pouring a concrete mixture into special molds, after which they undergo a drying and finishing process. Concrete paving tiles have high strength, wear resistance, and low cost, making them an economically viable option for many spatial solutions.

Stone paving tiles provide an elegant and natural look to the space. They are made from polished stone, which adds extra strength and wear resistance. Stone paving tiles are available in various colors and formats, allowing for the creation of exquisite design compositions.

Ceramic paving tiles are one of the most decorative options. They are produced by firing clay and applying glaze, making them resistant to moisture and dirt. Ceramic paving tiles are available in various colors, decorative patterns, and textures, allowing for the creation of unique compositions according to individual projects.

Natural paving tiles are made from natural stone, such as granite, marble, or travertine. They have a unique appearance and texture, as well as high strength and wear resistance. Natural paving tiles can be used to create exclusive architectural solutions.

The discussed types of paving tiles provide numerous opportunities for design decoration of the space. The choice of material depends on the planned style, functional needs, and project budget. Regardless of the chosen option, paving tiles will add attractiveness and practicality to your environment.

Design and Patterns in Paving Tiles

The use of design and patterns in paving tiles is an important aspect of creating a comfortable and attractive environment for gardeners and city residents. In addition to their functional qualities, which consist of creating a durable and stable surface, paving tiles also have significant design potential.

Design in paving tiles can be realized through various colors, textures, and shapes. Colors can be used to create bright or muted compositions, to highlight certain areas, or to create contrasting accents. The use of textures adds additional depth and visual interest to the tiles, emphasizing their uniqueness. The choice of shape of the tiles can allow for decorative inlays or original cuts during installation, giving the covering additional aesthetics.

Patterns in paving tiles can be arranged randomly or in a specific order, creating geometric or romantic compositions on the surface. Patterns can be relief or serve as inlays that create intricate designs or symbolism. The use of patterns can create harmony with surrounding architectural elements and landscapes or become a standalone accent that attracts attention and creates a unique atmosphere.

Design and patterns in paving tiles are an important factor in creating the atmosphere of a city, influencing the comfort and mood of pedestrians. They can express the identity and character of the area, stimulate cultural development, and support tourist attractiveness. Careful planning and attention to design details can enhance the aesthetics of the area and emphasize its individuality.

Quality and Properties of Paving Tiles

Paving tiles are one of the most popular materials used for arranging sidewalks and pedestrian paths. They are not only aesthetically pleasing but also make a significant contribution to ensuring the comfort and safety of pedestrians.

Quality of paving tiles is of great importance, as it determines their service life and resistance to environmental impacts and loads.

First of all, it is worth paying attention to the material from which the tiles are made. The most common materials are concrete and natural stone. Concrete tiles have their advantages, such as affordable price, a wide range of colors and shapes, as well as practicality. They are easy to install, wear-resistant, and frost-resistant. However, compared to natural stone tiles, concrete tiles may have less aesthetic appeal and require more maintenance to keep clean and beautiful.

A very important characteristic of paving tiles is frost resistance. The tiles must be resistant to thawing, meaning they should not break under low temperatures. This is important because changes in volume due to ice can lead to damage to the tiles and dangerous situations for pedestrians.

Anti-slip properties of the tiles also play an important role in ensuring safety. The surface of the paving tiles should be rough enough to prevent pedestrians from slipping, especially in rainy or snowy conditions.

In addition, durability and longevity of the tiles are also important factors. They must withstand the loads of pedestrians as well as various vehicles that may cross the sidewalk. It is important that the tiles do not break or crack under such loads.

Overall, considering all these factors, the quality of paving tiles is the foundation for creating a safe and comfortable pedestrian environment. Considering the properties and quality of the tiles when planning and constructing a sidewalk is an important aspect to ensure satisfaction from its use and long-term use.

Environmental Aspects of Paving Tile Production

In the modern world, the growing attention to environmental issues and the constant pursuit of sustainable development lead to the necessity of thoughtful selection of materials and technologies in construction. One of the segments where environmental aspects are of great importance is the production of paving tiles.

The use of eco-friendly materials and efficient resource utilization during the production of paving tiles is an important step in ensuring the environmental friendliness of this type of product. One of the most common materials in the production of paving tiles is concrete.

Concrete, while using a large amount of natural resources, can be an eco-friendly and energy-efficient material if its production is carried out using recycled raw materials and ultra-fine residues. Recycled raw materials can be obtained from crushed concrete or materials from renewable sources, such as old concrete products or waste. The use of such materials reduces the negative environmental impact of production and decreases the consumption of natural resources.

In addition to using eco-friendly materials, the environmental friendliness of paving tiles also depends on production technologies. The use of low-noise and low-explosive technologies in the production of paving tiles reduces the environmental impact on the surrounding environment and the health of workers. Additionally, the implementation of effective waste disposal and recycling systems can ensure a reduction in negative environmental impact.

Environmental aspects of paving tile production are of great importance for both preserving natural resources and ensuring a healthy environment for city residents. A responsible approach to the selection of materials and production technologies can help reduce the negative impact on the environment and contribute to the sustainable development of our society.

Use of Paving Tiles in Landscape Design

Paving tiles are an important element in landscape design, serving not only a decorative but also a practical function. They add style and sophistication to the appearance of the space while providing a comfortable and safe surface for pedestrians.

Style and Aesthetics

The use of paving tiles allows for the creation of a unique style and atmosphere in landscape design. Various shapes, colors, and textures of tiles enable the creation of different design solutions. They can be used to create patterns, borders, and other decorative elements that give the space originality and elegance.

Functionality and Safety

One of the main advantages of paving tiles is their functionality. They provide a level, stable, and smooth surface, making them an ideal material for sidewalks, alleys, and other pedestrian paths. Additionally, the use of paving tiles helps avoid problems with puddles during rain, as water quickly drains off their surface.

From a safety perspective, paving tiles can be equipped with special anti-freezing or anti-slip properties, allowing for the avoidance of accidents and falls for pedestrians.

Ecological Sustainability and Durability

Paving tiles are often made from eco-friendly and wear-resistant materials, such as concrete or natural stone. They are environmentally safe and harmless to the surrounding environment.

Moreover, paving tiles are known for their durability. When properly installed and maintained, they can last for many years without losing their decorative and functional properties.

Final Thoughts

The use of paving tiles is an important aspect of landscape design. They add style, aesthetics, and practicality to the space. By providing a comfortable and safe surface for pedestrians, paving tiles become an essential element in creating a harmonious and functional outdoor environment.

Innovations in Paving Tile Production

Innovations in the field of paving tile production play an important role in improving product quality, increasing its durability and aesthetics. Thanks to the application of new technologies and materials, the production of paving tiles becomes more efficient and competitive in the market.

One of the key innovations in paving tile production is the use of colored concrete. Instead of traditional gray, manufacturers can add paint or pigments to the concrete mixture, allowing for the production of paving tiles in various colors. This enables the creation of aesthetically pleasing coverings that harmoniously fit into any landscape.

Another significant achievement in paving tile production is the use of nanomaterials. Adding nanoparticles to the concrete mixture increases the strength and durability of the covering. Additionally, due to the nanostructure of the concrete, the tiles become more resistant to atmospheric conditions and mechanical damage. Such coverings ensure the longevity of paving tiles and reduce the need for repairs and replacements.

To ensure safety and comfort for users, eco-friendly materials are used in the production of paving tiles. For example, the tiles may contain natural fillers that make them more natural and organic. Furthermore, the special surface of paving tiles provides good anti-corrosion resistance, helping to avoid slipperiness and accidents during rain or freezing.

Another important innovation in paving tile production is the use of high-tech equipment and automation of the manufacturing process. This increases production efficiency and improves tile quality. Such approaches allow for reduced costs and shortened production times, which is beneficial for both manufacturers and buyers.

Overall, innovations in paving tile production open new prospects for improving the quality and functionality of products. They allow for the creation of tiles with new properties that meet environmental requirements, ensure safety and comfort for users, and have an aesthetic appearance. The implementation of innovative technologies in paving tile production is an important step in the development of the construction industry and meeting the needs of modern society.

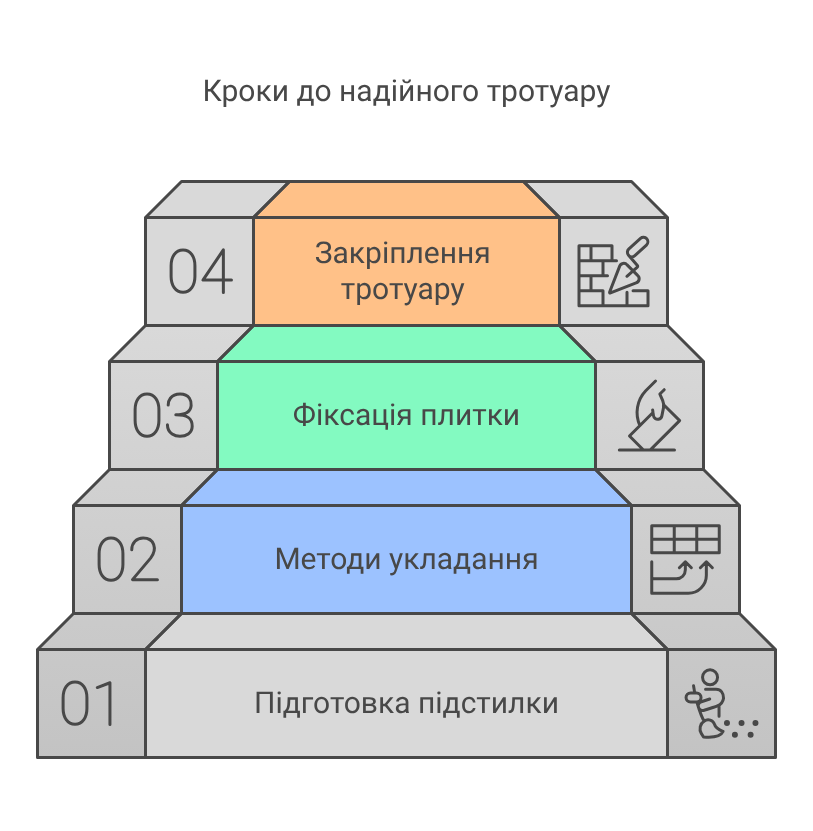

Paving Tile Installation Techniques

Installing paving tiles is the process of laying individual elements in the form of tiles on a surface to create a sidewalk. This process requires some skills and knowledge to ensure the strength, aesthetic appearance, and durability of the sidewalk.

Preparation of Base

The first step before laying paving tiles is to prepare the base. It should be level, stable, and well compacted. For this, gravel or sand can be used, which should be thoroughly compacted. If the base is not properly prepared, the tiles may begin to sink or crumble over time.

Installation Methods

There are several methods for laying paving tiles. One of them is the straight method, where the tiles are laid in a straight line. This method is the simplest and fastest, but at the same time, it requires great attention and precision. To ensure the tiles are evenly placed, guides or rails should be used.

Another method is the “checkerboard” method. In this method, the tiles are laid in a checkerboard pattern of mutually perpendicular rows. This allows for a more robust and load-resistant sidewalk. However, this method requires more time and effort in aligning the tiles.

Fixing Tiles

After the tiles are laid, they need to be fixed. For this, special glue or a cement mixture is used. By evenly distributing the glue or mixture on the base, the tiles are pressed down, making small movements side to side to ensure good adhesion. After this, the tiles should be leveled using rails or a trowel.

Securing the Sidewalk

The final step is securing the sidewalk. For this, a cement mixture is usually used, which is poured between the tiles and thoroughly compacted. This helps prevent the tiles from shifting and provides additional strength to the sidewalk.

Now that the basic techniques for laying paving tiles are known, you can confidently and effectively perform this work. Remember the proper preparation of the base, careful laying of the tiles, as well as fixing and securing the sidewalk to create a durable and aesthetic covering.

History of Paving Tiles: From Ancient Times to Modernity

Paving tiles, which are now an integral part of the urban landscape, have existed for centuries. They add beauty and functionality to streets and sidewalks, providing a safe and convenient surface for pedestrians. However, few consider the origins and development of this building material. In this section, we will explore the history of paving tiles from ancient times to modernity.

Ancient Times and Early Development of Paving Tiles

The extraction of clay from natural sources and its use for creating various building materials were known to the earliest civilizations. One such material, ceramic tiles, was used for flooring as early as Ancient Egypt and the Roman Empire. Invented about 4000 years ago, ceramic tiles were a convenient and aesthetic material, becoming popular in various countries around the world.

Development in the Middle Ages and Renaissance

In the Middle Ages, the use of ceramic tiles slightly declined, but they did not disappear from use. However, during the Renaissance, interest in construction and architecture grew again, leading to the development of paving tiles. They began to be produced by shaping clay into special molds and firing them. This process allowed for the production of strong and frost-resistant paving tiles, which became popular in Europe and other parts of the world.

Transition to Concrete Tiles in the 19th Century

In the 19th century, a new technology for producing paving tiles was invented, which changed the construction industry. This was concrete paving tiles. By mixing cement, sand, and water, this new material became extremely strong and durable. It was also more affordable to produce, contributing to its widespread adoption.

Modernity and New Production Technologies

In the modern world, paving tiles are produced in various ways, from traditional concrete casting to the use of computer control. New technologies allow for the creation of various shapes, colors, and textures, enabling the design of unique sidewalks and streets. Additionally, special coatings provide paving tiles with properties of environmental friendliness, durability, and wear resistance.

Modern Materials for Paving Tile Production

Today, the production of paving tiles is expanding and progressing, thanks to the development of new technologies and the emergence of modern materials. The extraction of natural stones, such as granite, concrete, and brick, is becoming less common as their advantages are replaced by other materials.

One of the new and eco-friendly materials for producing paving tiles is rubber. Rubber tiles are made from recycled automotive and bicycle tires. They possess properties that make them an ideal choice for sidewalks: high anti-corrosion resistance, strength, and durability. Additionally, rubber tiles have high frost resistance and do not slip even in wet conditions.

Another new material widely used in the production of paving tiles is glass aggregate. Glass aggregate is a type of recycled glass that has transparency and smoothness of surface. It is eco-friendly and has high resistance to weather conditions. Glass aggregate is used to create bright and original designs for sidewalks.

Moreover, the production of paving tiles encounters such new materials as polymer concrete and ceramic granite. Polymer concrete is a mixture of the main component material – concrete – and polymers, making it more wear-resistant and durable. Ceramic granite provides high strength and durability and can come in various colors and textures.

For the sake of environmental safety and resistance to weather conditions, materials made from natural composites are also gaining significant popularity. For example, tiles with wood filler and polymer binding have a natural appearance while being strong and wear-resistant.

In modern paving tile production, composite tiles and mountain sand are also becoming popular. Composite tiles are made from a hybrid material that combines the properties of concrete and polymers. They possess high strength, wear resistance, and frost resistance. Mountain sand is also a convenient option as it has a natural appearance and blends well with various landscape design styles.

Modern materials for paving tile production expand the possibilities for creating aesthetic and practical sidewalks. A wide selection of materials ensures the strength, resistance, and durability of the tiles in various climatic conditions. With modern materials, paving tiles can embody beauty and functionality in contemporary landscape design.