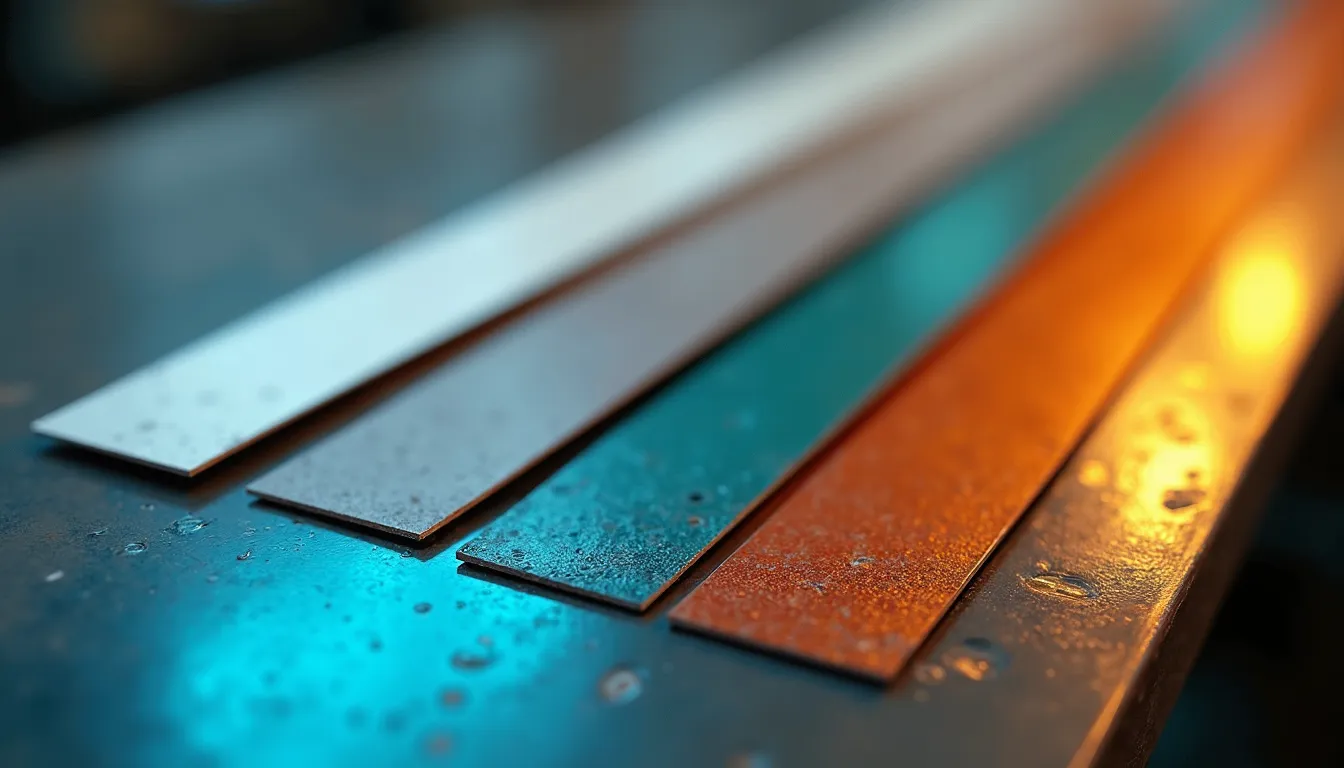

Laminated metal is a specially processed metallic material obtained by applying laminate to a metal base. This process imparts special physical and mechanical properties to the product, making it popular in many industries. Laminated metal differs from ordinary metal in its ability to withstand aggressive operating conditions and also has an aesthetic appearance due to the variety of colors and textures of the coating. Typically, materials such as aluminum, steel, or copper are used as the base, while the laminate can be made from polymers or other organics.

The main characteristics of laminated metal include:

- High strength — due to the multi-stage production process, laminated metal can withstand significant mechanical loads.

- Corrosion resistance — the laminate creates a protective barrier that prevents moisture and aggressive chemicals from penetrating.

- Aesthetics — laminated metal can have various colors and textures, making it attractive for decorative purposes.

- Lightweight — this material is lighter than many traditional metals, facilitating transportation and installation.

Research shows that laminated metal is gaining increasing popularity in Ukraine, especially in construction and industry. Given the need to reduce operating and maintenance costs, as well as to increase energy efficiency, the use of laminated metal is becoming not only justified but also an extremely relevant choice.

Interestingly, manufacturers specializing in laminated metal have already emerged in Ukraine, providing the local market with quality materials.

Thus, laminated metal is an innovative material that successfully performs the functions of both structural and decorative elements. Its versatility and efficiency make it indispensable in the modern construction industry.

Advantages of Laminated Metal

Laminated metal has numerous advantages that make it attractive for use in various fields. Here are some key advantages to consider:

- High wear resistance — due to the special coating, laminated metal has exceptional resistance to mechanical wear, ensuring the durability and reliability of the product.

- Reliable corrosion protection — the laminated coating effectively protects the base material from the negative effects of moisture, which is especially important in conditions of high humidity or aggressive environments.

- Aesthetic appearance — the variety of colors and textures makes laminated metal an ideal choice for design solutions in construction. This contributes to the realization of creative ideas, adding aesthetic value to buildings.

- Ease of processing — laminated metal is easy to process and install, reducing the time and costs required to complete construction projects.

- Cost-effectiveness — the use of laminated metal can significantly reduce operating and maintenance costs, as it does not require frequent repairs and replacements.

The advantages of laminated metal can be illustrated in practice. For comparison, let’s consider two materials — ordinary metal and laminated metal:

| Indicator | Ordinary Metal | Laminated Metal |

|---|---|---|

| Corrosion Resistance | Low | High |

| Aesthetic Appearance | Limited | Diverse |

| Weight | High | Low |

| Maintenance Cost | High | Low |

Interestingly, due to its versatility, laminated metal can be used not only in industry but also in everyday life, for example, for making furniture or decorative elements.

Laminated metal undoubtedly provides significant advantages that can change approaches to design and construction. Its technological characteristics and aesthetics make it not just a material for meeting needs but also an important element of modern art in construction.

Production Process of Laminated Metal

The production process of laminated metal is complex and multi-stage, ensuring its high quality and specifications. Production begins with the selection of the base material — usually steel, aluminum, or copper. At this stage, it is important to consider the future purpose and operating conditions of the finished product, as different materials have their unique properties.

The first step in the process is preparation of the base. The metal is cleaned of contaminants such as grease, dirt, and scale to ensure a quality bond with the laminate. Cleaning can be done mechanically or chemically, depending on production requirements.

The next stage is applying the laminate to the metal base. This process can be performed using various methods:

- Pressure Lamination — under high pressure, the laminate is pressed against the metal base. This creates a strong bond between the layers.

- Vacuum Lamination — in this case, air is removed from the interlayer to ensure ideal adhesion of microscopic parts.

- Hot or Cold Method — for some types of laminate, heating may be used to increase the plasticity of the materials, ensuring better bonding.

After applying the coating, the next stage is sealing and securing. Here, the laminate undergoes thermal treatment, which provides even greater resistance to mechanical loads and negative environmental influences, particularly moisture and temperature fluctuations.

The final stage is quality control. The finished product is checked for defects such as cracks, air bubbles, or unevenness of the coating. Various control methods are used, including visual inspection and wear resistance testing.

| Production Stages | Description |

|---|---|

| 1. Preparation of the Base | Cleaning the metal surface of contaminants. |

| 2. Applying the Laminate | Using various methods to ensure quality bonding. |

| 3. Sealing | Thermal treatment to enhance coating resistance. |

| 4. Quality Control | Checking the product for defects and compliance with standards. |

Interestingly, factories specializing in the production of laminated metal often implement new technologies, allowing them to reduce costs and improve product quality.

The production process of laminated metal is not only complex but also extremely important for ensuring high quality standards. Modern technologies used in manufacturing open new possibilities for the use of this material in various industries, including construction, automotive, and furniture industries.

Main Types of Laminated Metal

Laminated metal can be presented in various forms depending on the production methods and components used for applying the coating. There are several main types of laminated metal, each with its specific characteristics and applications. Let’s consider the most common ones:

- Laminated Steel — one of the most commonly used types. Thanks to its coating, this material has high resistance to corrosion and mechanical damage. Laminated steel is widely used in construction, automotive manufacturing, and the production of household appliances.

- Laminated Aluminum — a lighter and more corrosion-resistant option, mainly used for making building facades, roofs, and in packaging production. Aluminum has an aesthetic appearance due to the variety of colors and textures of the coating, making it popular in design.

- Laminated Copper — has excellent conductivity and corrosion resistance. It is often used in electronics and cable manufacturing, as it allows for high efficiency in electrical current transmission.

- Laminated Composite Metal — combines the properties of different materials, improving their operational characteristics. This type of laminated metal is usually used in the aerospace industry and for manufacturing specific parts that require high mechanical and thermal performance.

Each of these types has specific physical and mechanical properties that determine their use in various fields. For example, if you are planning to build a building facade, laminated aluminum would be an excellent choice due to its lightness and resistance to atmospheric influences. For manufacturing structures that experience significant loads, laminated steel is a better option.

| Type of Laminated Metal | Main Properties | Application Area |

|---|---|---|

| Laminated Steel | High strength, corrosion resistance | Construction, automotive manufacturing |

| Laminated Aluminum | Lightweight, aesthetic | Decorations, facades, packaging |

| Laminated Copper | High conductivity, corrosion resistance | Electronics, cables |

| Laminated Composite Metal | Combination of different physical properties | Aerospace industry, special parts |

Interestingly, each type of laminated metal can be tailored to specific production needs, enhancing its versatility and application possibilities.

Laminated metal is not just a material but also a platform for realizing ideas in various industrial fields. The choice of a specific type of laminated metal will influence the functionality and aesthetics of your project. Depending on the specifics of the task, you will be able to find the ideal option that best meets your requirements and operating conditions.

Application of Laminated Metal in Industry

Laminated metal has found wide application in industry due to its high characteristics that ensure the efficiency and durability of products. One of the key sectors where this material is popular is automotive manufacturing. For example, laminated metal parts used in car bodies significantly improve their resistance to corrosion and wear. This also contributes to reducing the weight of the vehicle, which is an important factor for increasing fuel efficiency.

Additionally, laminated metal is actively used in the production of household appliances — from refrigerators to washing machines. Due to its high wear resistance and aesthetic appearance, such metal allows consumers to obtain not only functionally capable but also aesthetically appealing products.

In the field of electronics, laminated metal demonstrates its usefulness by being used in cables and other elements of electrical systems. Laminated copper, due to its high conductivity and corrosion resistance, ensures reliable and long-lasting contact in challenging conditions. This approach is crucial for ensuring the operation of vital systems such as communication and information technology.

One of the exciting trends in the industrial application of laminated metal is its use in the production of finishing materials. For example, laminated panels that imitate natural wood or stone are actively used for interior and facade finishing of buildings. This allows designers to realize creative ideas, as laminated metal can be produced in various colors and textures, enriching aesthetics while improving operational characteristics.

| Application Area | Use of Laminated Metal | Advantages |

|---|---|---|

| Automotive Manufacturing | Bodywork, interior elements | Lightweight, corrosion resistance |

| Household Appliances | Refrigerators, washing machines | Aesthetics, wear resistance |

| Electronics | Cables, components | High conductivity, durability |

| Interior Finishing | Facade and interior panels | Diversity of textures, ease of processing |

Interestingly, due to its diversity and versatility, laminated metal can prove to be an ideal choice for completely different industrial applications.

Thus, the use of laminated metal in industry in Ukraine not only enhances production efficiency but also opens new horizons for implementing innovative projects. Its universal properties allow the material to be adapted to a wide variety of operating conditions, making it indispensable in the modern industrial sector.

Use of Laminated Metal in Construction

Laminated metal is noted for its versatility in construction, as it can perform numerous functions, from load-bearing structures to aesthetically appealing finishes. In light of modern trends, the material is used not only in commercial construction but also in the private sector. For example, laminated metal panels are actively used for cladding building facades, creating a stylish and modern look that attracts attention.

One of the key advantages of laminated metal in construction is its lightness, which significantly simplifies installation work. Specifically, due to this, such materials can be used not only in large industrial projects but also for equipping private homes and cottages. At the same time, laminated metal can withstand significant loads, making it an ideal choice for implementing various structures.

Additionally, it is worth noting that laminated metal can be used in roofing production. It has excellent water-repellent properties, significantly reducing the risk of moisture penetration, thus maintaining a comfortable microclimate within the building. During the production of roofs made of laminated metal, various shapes and designs can be achieved, allowing for easy adaptation to the style of any architecture.

The table below outlines the main applications of laminated metal in construction and its advantages:

| Application | Advantages |

|---|---|

| Facade Panels | Aesthetics, ease of installation |

| Roofing Materials | Moisture resistance, variety of shapes |

| Decorative Elements (fences, railings) | High wear resistance, design solutions |

| Interior Partitions and Cladding | Ease of processing, sound insulation properties |

Interestingly, laminated metal can be combined with other materials such as glass and wood, creating unique design solutions for modern interiors.

The use of laminated metal in construction allows for designing not only functional but also visually appealing spaces. Its properties, such as corrosion resistance and lightness, shed new light on building materials, ensuring durability and efficiency. At the same time, maintaining aesthetics always remains a priority, as clients want not only reliable but also beautiful buildings.

Environmental Aspects of Production and Disposal

The production and disposal of laminated metal have their environmental aspects that go beyond traditional notions of metal use. Before delving into these topics, it is important to understand that the processes associated with the manufacturing and recycling of materials can significantly impact the environment.

At the production stage of laminated metal, various technologies and raw materials are used that require energy and resources. For example, polymer materials are often used in the production of laminated panels, which may not be sufficiently eco-friendly. However, recent research has shown that through improved manufacturing methods, CO2 emissions, water, and energy consumption can be significantly reduced, making the process more sustainable.

An integral part of the ecological cycle is the disposal of laminated metal. After the end of their service life, products made of laminated metal can be recycled. A significant achievement is that many of these materials are recyclable, thereby reducing the need for primary resources. In Ukraine and Europe, systems for collecting and recycling metals have already been established, positively impacting the reduction of the ecological footprint of industry.

Here are some key aspects that influence the environmental component of the production and disposal of laminated metal:

- Use of renewable materials — companies are increasingly transitioning to the use of secondary resources and eco-friendly materials in the manufacturing process.

- Waste reduction — modern technologies allow for reducing the amount of waste generated during metal processing and promote the reuse of resources.

- Energy conservation — eco-friendly processing methods and new energy solutions allow for reducing energy consumption in production.

- Environmental protection — with the implementation of environmental standards, the quality of production improves, and the impact on nature decreases.

| Aspect | Impact on Ecology |

|---|---|

| Production | Reduction of emissions; energy conservation |

| Disposal | Recycling; reuse of resources |

| Use | Reduction of resource costs; durability |

Interestingly, modern technologies in Ukraine allow for reducing the negative impact on the environment, making production processes more efficient and eco-friendly.

Laminated metal, due to its unique properties, has enormous potential not only for the economy but also for environmental protection. The use of eco-friendly technologies in production and disposal can have long-term positive effects on sustainable development, as it ensures a balance between human needs and the preservation of natural resources. Thus, investments in such solutions become crucial for the future of both industry and our planet.

Market Development Prospects for Laminated Metal

Today, the market for laminated metal demonstrates positive growth dynamics, driven not only by innovations in production but also by increased demand from various sectors. In particular, due to their versatility and durability, laminated metals are actively being implemented in both the construction sector and industry. The growing need for quality and eco-friendly materials encourages manufacturers to invest in new technologies and improved processing methods.

Among the key trends in market development, the following can be highlighted:

- Environmental responsibility — more and more enterprises are implementing sustainable development principles, incorporating environmental standards into their production processes. This reduces the negative impact on the environment.

- Adaptability to new technologies — manufacturers are actively adopting the latest lamination technologies, improving quality and reducing production costs.

- Expansion of the product range — the variety of laminated metals is increasing, allowing for meeting the specific requirements of various industries, from automotive to advertising.

- International cooperation — Ukrainian manufacturers are increasingly collaborating with international partners, exchanging experiences and technologies, which contributes to improving product quality.

No less important is the aspect of innovative solutions that have less impact on resources and also reduce production costs. For example, new technologies for creating laminated metal have emerged that use less energy and water compared to traditional methods. This is a significant advantage in the context of increasing pressure on natural resources.

For the Ukrainian market, the growing interest in the use of laminated metal in construction and architecture creates new opportunities for development. Investing in new enterprises capable of producing laminated metal can lead to a significant increase in the competitiveness of domestic manufacturers. This will not only ensure market stability but also create new jobs.

According to recent studies, it is expected that over the next few years, the demand for laminated metal in Ukraine will grow by 15-20%, indicating the viability of this sector.

Thus, the future of the laminated metal market looks promising, as it responds to the modern challenges facing industry and construction. The continuous evolution of technologies and the growing awareness of consumers make this material an integral part of sustainable development in Ukraine.