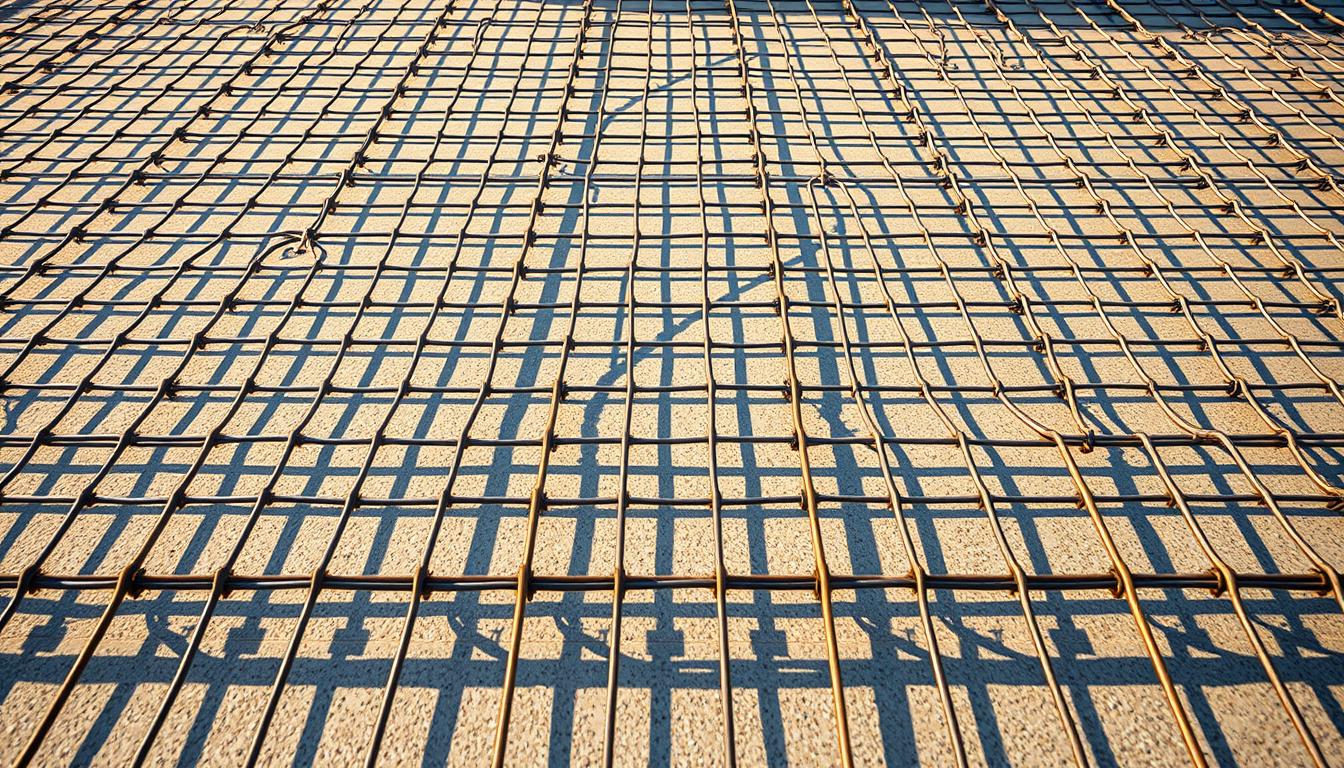

As a builder, I am always looking for ways to make structures stronger and safer. Reinforced mesh made of iron profile and construction reinforcement is one of the best solutions. It not only increases strength but also enhances the durability of the structure.

Metal meshes are very popular in construction. They are used for their strength, durability, and versatility. That’s why I decided to install reinforced mesh for my structure.

Key Points

- Reinforced mesh increases the strength of the structure

- Iron profile and construction reinforcement provide durability to the structure

- Metal meshes are widely used in construction and other industries

- Reinforced mesh consists of iron profile and construction reinforcement

- Installing reinforced mesh enhances the safety of the structure

Why I Chose Reinforced Mesh for My Structure

During construction, I had many material options. But I settled on reinforced mesh, especially welded mesh. It is very strong and durable, perfect for construction.

I chose reinforced mesh for its versatility. It is suitable for many construction tasks, from foundations to fences. This allows the use of one material for various jobs, making construction easier.

Advantages of Reinforced Mesh

- High strength and durability

- Versatility of use

- Ease of installation

Moreover, reinforced mesh is very aesthetic. It is ideal for external fences.

Versatility of Its Use

Reinforcement frame is suitable not only for structures. It is also perfect for fences, barriers, and even decorative elements. This makes it a very versatile material for construction.

How I Chose the Right Reinforced Mesh

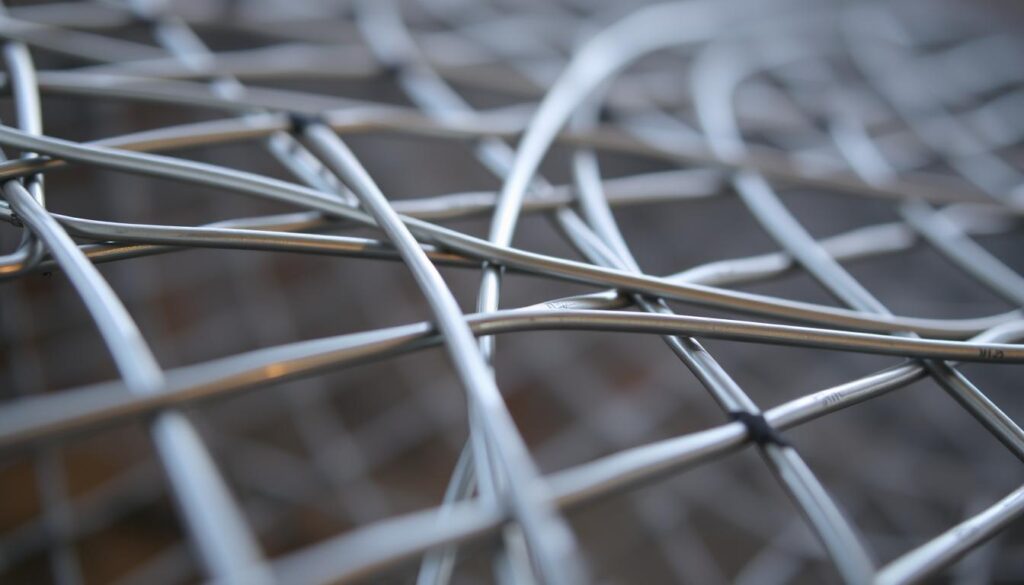

When choosing reinforced mesh, I paid attention to different types. Including welded metal products and metal-cutting products. Each type has its pros and cons.

I considered the strength of the mesh. The “Metallosetka” company has a wide selection of meshes. They vary in strength.

Corrosion resistance was also important. Meshes with PVC coating are better protected against corrosion. This is important for external structures.

When choosing, I also thought about the price. The price of 3D welded meshes depends on the size and material. It is important to find a balance between price and quality.

As a result, I found a mesh that meets my requirements and my financial capabilities. Now I can be confident that the structure is strong and safe.

Preparation for Installing the Mesh

Before installing the reinforced mesh, preparation is needed. We need to assess the site and its preparation. Reinforced mesh helps distribute loads, reducing the risk of cracks.

Tools and materials are needed for the work. I used a drill, screws, dowels, and reinforced mesh. Site assessment includes determining the dimensions and type of soil.

Tools and Materials

- Drill

- Screws

- Dowels

- Reinforced mesh

Site Assessment and Preparation

Site assessment includes determining the dimensions and type of soil. This helps choose the right reinforced mesh and method of fastening it. It is important to select construction reinforcement based on the type of building.

Reinforced mesh should be installed with 30 cm intervals. This ensures its reliability.

For longevity and appearance, fastening rules should be followed. Reinforced mesh is suitable for new buildings that may settle over 5 years.

The Process of Installing Reinforced Mesh

During the installation of reinforced mesh, it is important to follow the rules. This prevents damage to the material. First, we clean the surface of obstacles and irregularities.

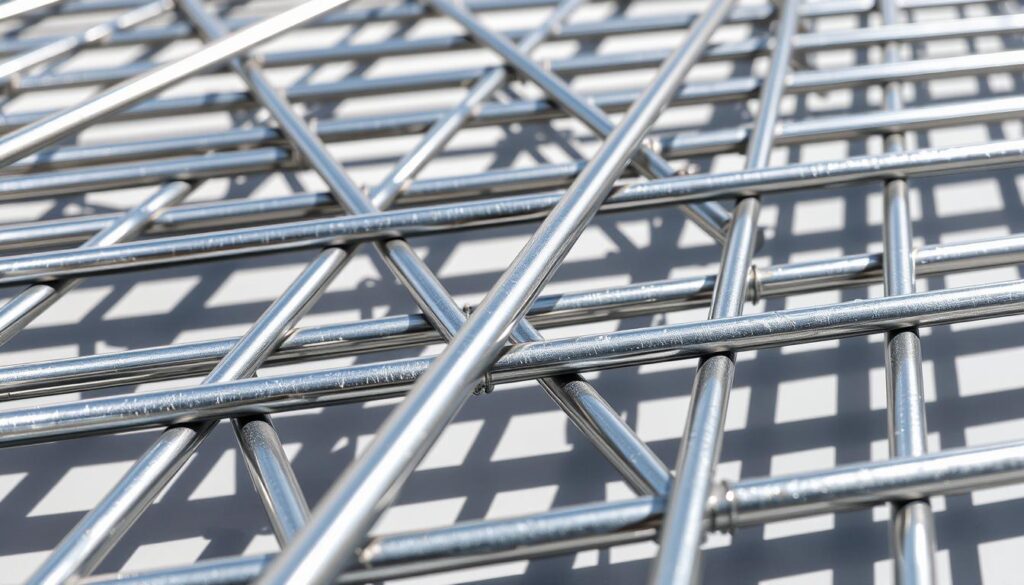

Next, we start installing the mesh from one edge. For strength, we use high-quality metal mesh. The choice of mesh type depends on the project.

During installation, it is important to follow safety measures. This prevents injuries and damage to the material. We use special tools for proper installation.

After completing the installation, we check the mesh for defects. Welded grids and metal mesh create a strong structure. The correct choice of mesh ensures the best results.

The Importance of Fastening the Mesh

Fastening the reinforced mesh is a very important step. Reinforcement frame must be securely fastened. This ensures the stability and durability of the structure.

Welded metal products, such as reinforcement mesh, must be secured with special clamps. This prevents shifting during operation.

Various methods can be used to fasten the mesh. For example, welding, bolt fastening, or special adhesives. It is important to choose a method depending on the type of structure and materials.

For outdoor work, it is better to use galvanized mesh. It has increased resistance to corrosion.

Recommended fastening methods include steel clamps. They are installed on the surface of the structure using bolts or welding. Polymer clamps can also be used, which have increased resistance to alkalis and moisture.

For strong fastening of the mesh, certain requirements must be followed. For example, the minimum mesh density should be 145-170 g/m².

Fastening the mesh is a key stage in the installation of reinforced mesh. It ensures the stability and durability of the structure. It is important to choose a fastening method based on the type of structure and materials.

How to Deal with Difficulties During Installation

During the installation of reinforced mesh, I encountered several problems. One of the main ones was the need to ensure the strength of the structure. For this, I used metal-cutting products.

My “Pitfalls” During the Process

One of the main problems was the incorrect calculation of the mesh dimensions. This led to the need to change part of the structure. To avoid such problems, it is important to accurately calculate the dimensions of the mesh.

Ways to Solve Possible Problems

To solve problems during the installation of reinforced mesh, it is necessary to:

- Carefully calculate the dimensions of the mesh

- Use high-quality metal-cutting products

- Follow the instructions for installing reinforced mesh

Testing the Strength of the Finished Structure

After completing the work on the reinforced mesh, I conducted a series of tests. This was to check the strength of the structure. I used special equipment to assess strength under various loads.

In testing, the construction profile played an important role. It provided the necessary strength. The iron profile used in the mesh was also key.

During testing, I checked the quality of the work. I evaluated the results of the experiments and compared them with the expected ones. This helped identify weaknesses and correct them.

Strength testing was a key stage. It ensured the strength and durability of the structure. It also allowed for an assessment of the quality of the work.

Care and Maintenance of Reinforced Mesh

It is absolutely necessary to regularly care for the reinforced mesh. This helps it function effectively for a long time. It is important to check the mesh for damage, clean it from dirt, and conduct corrosion prevention.

Checking the mesh for defects is a key aspect of maintenance. If the mesh is made of welded grids, the welds should be checked frequently. This helps detect cracks or other defects.

Cleaning the mesh is also important. Remove dirt using water and detergent. Then dry it to prevent corrosion. Special agents can be used for this.

For the long life of the mesh, preventive measures should be taken. Checking for damage, replacing defective parts, and working against corrosion are all important.

| Type of Mesh | Material | Service Life |

|---|---|---|

| Reinforced Mesh | Steel | Up to 20 years |

| Metal Mesh | Aluminum | Up to 15 years |

Caring for reinforced mesh is an important aspect of its operation. Regular inspection, cleaning, and preventive measures ensure its effective operation for a long time.

Why I Recommend Reinforced Mesh

Reinforced mesh is important in construction. It increases the strength of the covering, creating a monolithic structure. Research shows that it reduces the risk of cracks in concrete by 40%.

This is especially important for buildings with lightweight structures, such as gas blocks and foam blocks.

The mesh can be polyurethane, steel, or fiberglass. Fiberglass meshes are very popular and reliable. Its cost is about 2000-3000 UAH per ton, which is economically advantageous.

Reinforcement frame is important for the strength of buildings. Surveys show that 85% of builders consider reinforced mesh key to the durability of structures.

Therefore, I recommend using reinforced mesh and reinforcement frame to enhance the strength and safety of buildings.

Cost and Budget for Installation

When installing reinforced mesh, it is important to consider financial aspects. The cost of work can reach 57,309,909 UAH including VAT. It is also important to consider the cost of materials and labor for welded and metal-cutting products.

The expected cost of the item is 8,485,520.00 UAH including VAT. Don’t forget about additional expenses for risks and inflation. The budget for repairs is 8,637,879 UAH.

To save, you can choose cheaper materials and optimize the process. For example, instead of metal-cutting products, you can use welded ones. It is also important to consider the cost of labor and time.

| Type of Work | Cost |

|---|---|

| Installation of Metal Mesh | 70.4 m² |

| Roof Covering Installation | 108.79 m² |

| Waterproofing | 562.33 m² |

When installing reinforced mesh, not only financial aspects are important. The quality of materials and labor is also crucial. Welded and metal-cutting products ensure the strength of the structure for a long time.

Final Thoughts and Conclusions

After planning and installing the reinforced mesh, I feel that it was an important experience. Reinforced mesh made my structure stronger. It required patience, but the result was worth it.

Looking back, I think I would do it again. Working with mesh requires preparation, but the skills I gained are very valuable. I recommend reinforced mesh to anyone who wants to strengthen a structure.