Sliding gates DIY – is a great way to make gates yourself. You can make them from simple materials and tools. This will allow you to create gates that will be perfect for you.

Such a project not only saves money. It also allows you to create a unique design. Your home will reflect your personal style.

You can make sliding gates from various materials, such as metal or wood. It is important that they meet your needs. Homemade gates are a great choice for those who love to work with their hands.

Sliding gates: key points

Homemade sliding gates are not just a construction. They also provide security and functionality. In this article, we will tell you how to make them.

Key points

- Sliding gates DIY – is a practical solution for those who want to create their gates independently.

- Sliding gates DIY can be made using simple materials and tools.

- How to make sliding gates yourself depends on your needs and desires.

- Sliding gates DIY – is not only saving money but also the opportunity to create a unique design.

- Sliding gates DIY can be made using various materials such as metal, wood, and others.

- Sliding gates DIY – is not only about creating gates but also ensuring their security and functionality.

What are sliding gates?

Sliding gates consist of a frame that moves along a guide. They are reliable, practical, and suitable for various conditions. You can make them yourself or order from a specialized company.

It is possible to make sliding gates yourself if you have the necessary materials and tools. This is an ideal way to save money and create something with your own hands. But if you lack experience, it is better to turn to professionals.

- Reliability and durability

- Practicality and ease of use

- Ability to use in various conditions

- Option to make it yourself, i.e., DIY sliding gates

Sliding gates are suitable for many places, such as private homes or businesses. They are great for those looking for reliable and convenient gates.

Necessary materials for manufacturing

To create sliding gates by yourself, you need to choose metal parts. For example, a profile pipe with dimensions of 50 by 50 mm or 60 by 40 mm. They will be the basis of the frame.

For filling the gates, you can use wood or other materials. For example, metal profile or louvered fillings. For automation, appropriate automation is needed, depending on the sizes.

Don’t forget about the tools for work. For example, rollers, guides, electric drives. The instructions should specify all the necessary materials and tools.

When making sliding gates, it is important to consider the dimensions. Width from 3 to 6 meters, height from 1.6 to 2.2 meters. The standard size: width 4 meters, height 2 meters, leaf length 6 meters.

Designing the gates

Sliding gates in Ukraine have become popular due to their convenience and security. Designing is a key stage of production. Here, the dimensions, style, and materials are determined.

When designing, it is important to consider the width, height, and materials. Sliding gates open and close without taking up extra space.

Special programs are used for designing. They allow you to create accurate plans. Such plans will be executed according to all requirements.

| Parameter | Description |

|---|---|

| Width of the passage | Up to 4.20 m |

| Height of the gates | From 1.5 to 2 meters |

| Materials | Metal, wood, profiled sheet |

Designing is important for the production of gates. Here, the dimensions, style, and materials are determined. Sliding gates are ideal for convenience and security.

Preparing the site

The first action when installing sliding gates is preparing the site. This includes clearing the area, measuring, and marking. Metal sliding gates require precise preparation to ensure their proper installation.

When installing sliding gates yourself, it is important to carefully approach the site preparation. We need to determine the dimensions of the area, clear it of obstacles, and conduct marking. Remember that the weight of “average” sliding gates can reach 500 kg.

To prepare the site, perform the following actions:

- Clearing the area of obstacles

- Measuring the area to determine the dimensions

- Marking the area for gate installation

During the site preparation, it is important to consider recommendations. For example, the depth of the foundation, the thickness of the sand and gravel cushion, as well as the width of the pit. It is recommended that the depth of the foundation be at least 1.3 m, and the thickness of the cushion be at least 30-40 cm.

Metal sliding gates require careful site preparation. This ensures their proper installation and safe operation. Attention to site preparation is key to successful installation.

Making the gate frame

First, you need to choose the materials. Profile pipes sized 50 by 50 mm or 60 by 40 mm are often used. The dimensions of the gates can be from 3 to 6 meters wide and from 1.6 to 2.2 meters high. A welding machine, wrenches, and other tools are needed for work.

Making sliding gates yourself requires experience and knowledge. Instructions and diagrams will help you. The website mastervorot has a lot of useful information.

To create the frame, you need to perform several steps:

- Determine the dimensions and materials.

- Cut the profile pipes to size.

- Weld the pipes to form the frame.

- Add adjusting supports and other details.

Creating the frame is a key stage in making sliding gates. These steps will help create a sturdy frame that will last long.

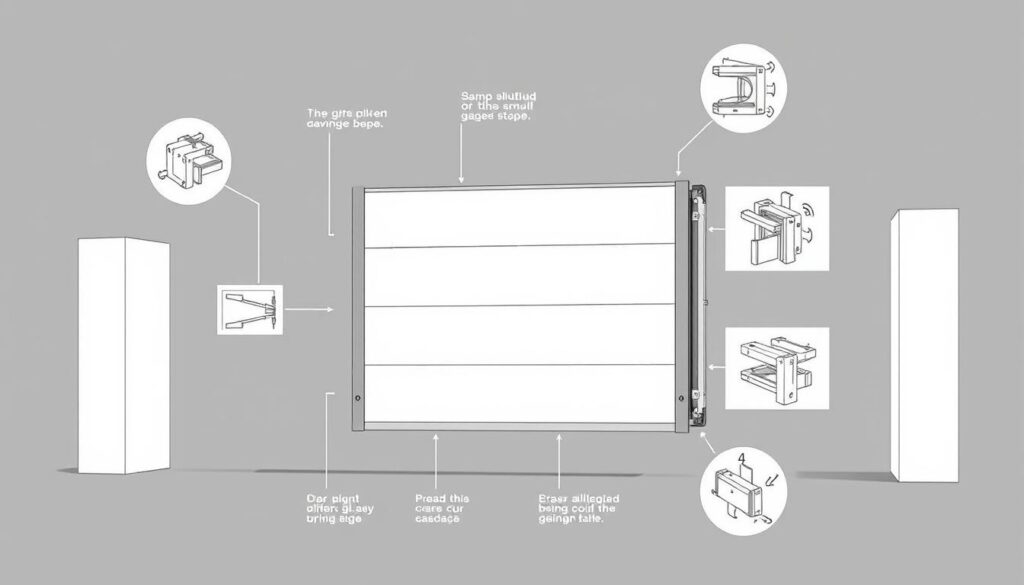

Installing the guides

Sliding gates require attention when installing the guides. It is important to choose the type of guides and perform the installation. Making such gates yourself is possible if you follow the instructions and use the right materials.

Before starting, you need to decide which guides will be needed. They can be metal or polymer. Metal guides are more reliable, but polymer ones are lighter and easier to install. It is important to choose guides that fit the size and weight of the gates.

Choosing the type of guides

The choice of guides depends on the weight and size of the gates. For light gates, polymer guides are better suited. For heavier ones – metal. Making gates yourself requires following instructions and using the right materials.

Installation process

Installing the guides includes several stages. First, we attach the guides to the posts. Then we install the roller supports on the guides. A proper approach to installation ensures the normal operation of the gates.

Making sliding gates yourself is possible if you follow the instructions and use the right materials. A proper approach to installing the guides is important for the normal operation of the gates.

Installing the gates themselves

The installation instructions for sliding gates should be detailed. It should describe how to attach the gates to the frame and adjust the opening mechanism. For this, you need to gather all the necessary materials and tools.

Sliding gates are popular in Ukraine due to their convenience and security. Choosing a location for installation is important. It is essential to consider the dimensions of the gates and the protected area. After that, the attachment to the frame is done using special fasteners.

Adjusting the opening mechanism includes installing the guides. This ensures the movement of the gates. For this, special tools and materials are needed, such as metal pipes.

The instructions should cover all stages of installation. This includes attachment to the frame, adjusting the opening mechanism, and other important aspects. With its help, you will be able to install the gates yourself.

Treating the gates

Metal sliding gates should be well treated to serve long. Protection from corrosion is a key stage. This is especially important as they often come into contact with rain, snow, and high humidity.

To protect against corrosion, various methods can be applied. For example, painting, galvanizing, or special coatings. When choosing a method, it is important to consider the strength and durability of the gates.

Sliding gates can also be decorated with various materials, such as wood, metal, or plastic. Decorating enhances their appearance. You can find instructions on the website sliding gates DIY.

With proper treatment and decoration, metal sliding gates can be very attractive and durable. They will be not only functional but also visually appealing.

For a long service life of sliding gates, they need to be regularly checked and maintained. This includes checking mechanisms, cleaning, and applying corrosion protection.

Control systems

DIY sliding gates require an effective control system. It automates the opening and closing. For this, you need to choose the right components, such as a rack, drive, and control device.

The gap between the guide rail and the roller supports should be 1-2 mm. This ensures the proper operation of the gates.

To automate the opening, drives are used. They can be mechanical or electric. The mechanical disconnection system is cheaper but may not work in winter.

Electric drives, such as the Miller Technics 1000 model, are suitable for large gates. They can be installed for lengths up to 10 m and weights up to 1000 kg.

Remote controls allow you to control sliding gates from a distance. They can have from 2 to 4 channels. The range varies from tens to hundreds of meters.

For safety, it is important to connect photo elements. They should be installed at a height of 50-60 cm above the ground.

The minimum configuration for an automatic system includes 3 components. This is the drive, control device (usually with 2 remote controls), and rack (4 meters for 3-meter passages).

When choosing a control system, it is important to consider technical parameters. For example, voltage, number of turns, and maximum current.

Testing and adjustment

DIY sliding gates require attention during testing and adjustment. They should be installed and adjusted according to the instructions. This will help avoid problems during their use.

When checking the system, it is important to check the roller supports and guides. You should also check the level of the leaf and its movement. This will ensure the free movement of the gates.

System testing

Testing sliding gates includes checking their operation. For example, you need to check how they open and close. It is also important to check their movement in different directions.

Troubleshooting

If problems are found during testing, they should be corrected immediately. Sliding gates may require adjustment or replacement of damaged elements.

Sliding gates should be installed and adjusted according to the instructions. This will ensure their proper operation. Proper testing and adjustment will help avoid problems and ensure durability.

- The width of the opening for sliding gates is typically from 3 to 4 meters

- The height of the opening usually ranges from 1.8 to 2.5 meters

- The depth of the pits for installing posts should be at least 1 meter or to the depth of soil freezing

Maintenance of sliding gates

Sliding gates require regular inspection and maintenance. This helps ensure their proper operation and long service life. For example, a series of actions must be performed to prevent breakdowns.

Regular inspection of the opening and closing mechanism is very important. This helps identify problems at an early stage. It is also necessary to periodically clean and lubricate the mechanism for smooth operation.

Repairing and replacing failed elements is an important aspect of maintenance. For this, you need to have the right tools and knowledge. Sliding gates instructions can help in this process.

Regular maintenance and servicing of sliding gates are very important. This prevents many problems and ensures safety and convenience of use. If properly maintained, they can be very reliable and durable.

Useful tips for manufacturing

Creating sliding gates is an exciting process. But it requires attention to detail and careful preparation. We have shared some useful tips to help you avoid mistakes.

Common mistakes and how to avoid them

One of the most common mistakes is incorrect measurement of the area. It is important to measure the width and height of the opening accurately. This will ensure the correct fitting of the sections.

It is also important to calculate the load on the guides. This will help avoid jamming or jerking when opening.

Recommendations from professionals

Professionals advise using durable materials. For example, galvanized pipes and quality fittings. This will ensure the durability of the structure.

Don’t forget about protection against corrosion. Painting and regular maintenance will help extend the service life. Sliding gates in Ukraine and advantages of sliding gates are key aspects.