Self-leveling floors are a modern material for your home. They are even, strong, and durable. Installation is not complicated if you know how.

To start, refer to the resource self-leveling floor. There is a lot of useful information there.

If used correctly, self-leveling floors can last for decades. It is important to choose the right material and follow the instructions.

Installing a self-leveling floor requires knowledge. But with the right approach, you can make it strong and beautiful.

Key Points

- Self-leveling floors can last for decades with proper use.

- Installing a self-leveling floor is not a complicated process.

- Self-leveling floors are eco-friendly and do not harm the environment.

- The cost and characteristics of materials for self-leveling floors can be found on the manufacturer’s website.

- A competent approach to laying self-leveling floors ensures a long service life of the covering.

What is a self-leveling floor?

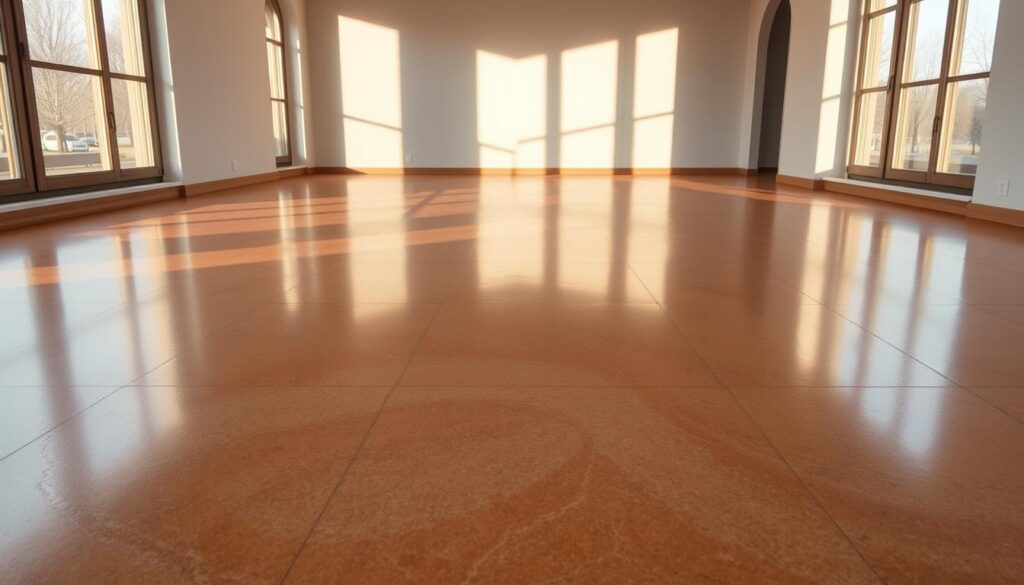

A self-leveling floor consists of a layer of mixture applied to the floor base. It hardens, creating a strong and smooth surface. Such a floor can be used in many places, for example, in industrial premises or residential buildings.

When choosing a self-leveling floor, it is important to pay attention to its advantages. It is very strong, durable, and wear-resistant. This is very important for places where many people walk.

Self-leveling floors tolerate moisture very well. This makes them ideal for bathrooms, kitchens, and other areas with high humidity. They can also come in various colors and effects, allowing you to make the interior unique.

For installing a self-leveling floor, you need to choose the right type of mixture. This depends on the type of room and its operating conditions.

When choosing a self-leveling floor, it is important to pay attention to its composition, thickness, and service life. Self-leveling floors can last for decades if used correctly. For comfort in residential areas, additional costs may be required for the installation of a heated floor system.

How to choose a self-leveling floor depends on many factors. This includes the type of room, its operating conditions, and personal preferences.

Why did I choose a self-leveling floor?

Self-leveling floors are very strong, durable, and wear-resistant. They are easy to clean and do not require special care. I chose them for their beauty, durability of the material, and ease of maintenance.

The price of a self-leveling floor can vary depending on the materials. But the advantages of a self-leveling floor make it a valuable investment.

More about the advantages of a self-leveling floor can be read in the article all about self-leveling floors. A self-leveling floor forms a solid layer based on a liquid material. This ensures its strength and durability.

The price of a self-leveling floor starts from 300 hryvnias per m², depending on the materials. But the advantages of a self-leveling floor make it a valuable investment. It effectively levels surfaces with minor imperfections due to its liquid consistency.

Preparation for Installation

Before installing a self-leveling floor, several important steps need to be taken. The first is preparing the floor. This includes checking it for cleanliness and removing dirt, dust, and oils. It is also important to choose materials for installation so that the floor is durable and looks attractive.

Statistics show that self-leveling floors have become 30% more popular in recent years. This means that many people want to have them in their homes and offices. But to make the right choice, you need to know which self-leveling floor meets your needs.

Preparing the floor for the installation of a self-leveling floor includes several stages:

- cleaning the floor from dirt, dust, and oils

- choosing the right materials for installing the self-leveling floor

- preparing the tools that will be necessary for installation

Experts recommend spending 2 to 5 hours preparing the floor, depending on its condition. You should also spend up to 15% of the installation cost on preparing the base.

During the preparation of the floor, it is important to consider several factors. For example, the moisture of the base, the strength of the concrete base, and the presence of rotten boards. All these factors should be taken into account when choosing materials for installation so that the floor is durable and attractive.

The Process of Installing a Self-Leveling Floor

Installing a self-leveling floor can be done independently. But this requires certain knowledge and skills. The process includes several stages: mixing components, applying the material to the floor, and monitoring the level and quality.

The thickness of the self-leveling floor material can range from 0.5 cm to 4 cm. The drying time depends on the material and environmental conditions. Usually, it takes from 24 to 72 hours.

When choosing a self-leveling floor, it is important to consider several factors. These include the thickness of the material, drying time, and cost. Epoxy self-leveling floors cost 180 UAH/m². The price of polyurethane self-leveling floors ranges from 140 to 145 UAH/m².

During the installation of a self-leveling floor, it is important to follow several rules. These include mixing components, applying the material evenly, and monitoring the level and quality.

- Mixing components according to the instructions

- Applying the material evenly to the floor

- Monitoring the level and quality of the self-leveling floor

If you want to install a self-leveling floor yourself, you need to have certain knowledge. But if you lack experience, it is better to turn to professionals. They can do it quickly and efficiently.

Drying and Curing Time

The time required for the self-leveling floor to dry depends on several factors. Among them are air temperature and humidity. Usually, it takes from a few days to a week.

The price of a self-leveling floor varies depending on the materials. The advantages of a self-leveling floor are its durability and ease of maintenance.

According to data, the drying time of self-leveling floors can be from 2 to 6 days. The curing time of the mixture is from 1 to 3 hours. Below is a table with the time after which walking on the self-leveling floor is allowed, varying depending on the manufacturer:

| Manufacturer | Time after which walking is allowed |

|---|---|

| Horizont | 6 hours |

| Unis | 24 hours |

| Ivsil | 3 hours |

| Volma | 7 hours |

| Base | from 12 to 24 hours |

The total drying time for polyurethane floors is 2 days. The total drying time for epoxy floors is up to 5 days. The total drying time for cement-containing self-leveling floors is up to 7 days.

The optimal humidity for drying should not exceed 60-65%. The air temperature should be between 22-25 degrees Celsius.

Care for Self-Leveling Floors

Self-leveling floors do not require much care. It is important to carry out wet cleaning in a timely manner. For maintenance, it is better to use soft agents.

During the installation of a self-leveling floor, it is important to prepare the base well. Improper preparation can lead to cracks. They occur due to debris on the surface.

To ensure the floor lasts long, it is necessary to regularly check it for damage. Removing stains and dirt will help preserve it. Avoid aggressive chemicals that can damage the floor.

When choosing a self-leveling floor, it is important to consider its type. Polyurethane and methyl methacrylate floors are suitable for residential use. Epoxy coatings are better suited for industrial premises.

Cost Estimate

The estimate for a self-leveling floor depends on many factors. These include materials, tools, and labor. But self-leveling floors are very strong, durable, and wear-resistant. This makes them a good long-term investment.

When calculating the costs for a self-leveling floor, it is important to consider several factors. These include the price of the self-leveling floor, the cost of materials, tools, and labor. The total cost includes direct expenses and overhead, such as wages.

A self-leveling floor is very strong, durable, and wear-resistant. This makes it a good choice for the long term. Additionally, it can be installed on any surface, making it a versatile solution.

When choosing materials for a self-leveling floor, it is important to consider price, quality, and durability. The cost of materials depends on the type and quality. Choose materials that meet your needs and budget.

Common Installation Mistakes

During the installation of a self-leveling floor, various mistakes can occur. They can affect the quality and strength of the floor. For example, improper leveling of the surface can lead to an uneven floor.

Another mistake is the wrong choice of materials. For example, high-traffic areas require materials with a high wear resistance class. It is better to consult specialists when choosing a self-leveling floor.

To avoid mistakes during the installation of a self-leveling floor, you should follow several tips:

- Before installing the self-leveling floor, it is necessary to prepare the surface well.

- Choose materials that meet your needs and operating conditions.

- Follow the installation instructions for the self-leveling floor.

If you follow these tips, you can avoid common mistakes. You will get a high-quality floor that will last a long time.

User Experiences

When choosing a self-leveling floor, it is important to pay attention to the experiences of other users. Installing a self-leveling floor can be a complicated process. But with advice from professionals, many mistakes can be avoided.

How to choose a self-leveling floor that meets your needs and is durable?

User reviews indicate that epoxy floors are one of the most popular options. They have high wear resistance, chemical resistance, and moisture resistance. This makes them ideal for various premises.

For example, an epoxy floor in a garage or service station is not afraid of petroleum products and is easy to clean.

Users recommend three main options for epoxy floors: Plastall, Novachok, Epoxy ART, depending on the purpose and load. The Epoxy ART epoxy floor offers a wide range of colors and patterns. It is suitable for creative projects.

When choosing a self-leveling floor, it is worth paying attention to the following factors:

- High wear resistance

- Chemical resistance

- Moisture resistance

- Easy cleaning

- Durability

Installing a self-leveling floor can be expensive. But due to its durability, it pays off. An epoxy floor can last for decades without damage.

This makes it a good investment for those who want to make their home or office more comfortable and beautiful.

How to Avoid Installation Problems?

During the installation of a self-leveling floor, it is very important to plan well. It is important to choose the right materials, tools, and people. You should also strictly follow the instructions.

A key point is choosing the right self-leveling floor. It should meet the requirements of the room, moisture levels, and mechanical loads. For example, polyurethane coatings are very strong and durable, so they are often used in industry.

To avoid problems, several requirements should be followed. The maximum deviation of the floor should not be more than 4 mm. The moisture of the concrete base should not exceed 4%. The temperature in the room during pouring should be between 15-25 °C, and the humidity should not exceed 80%.

To avoid problems with the installation of a self-leveling floor, it is necessary to plan well. It is important to choose the right materials, tools, and people. You should also strictly follow the instructions.

Conclusions

I chose a self-leveling floor for its practicality and durability. This modern covering provides an even, strong surface. It is also wear-resistant and easy to maintain.

With a wide selection of colors, self-leveling floors fit perfectly into my interior.

For those considering self-leveling floors, it is important to prepare the base well. Next, follow the installation technology. Do not skimp on the quality of materials.

This approach will help avoid problems. You will get a covering that will be durable, aesthetic, and practical. Installation may take time, but the result will be worth it!