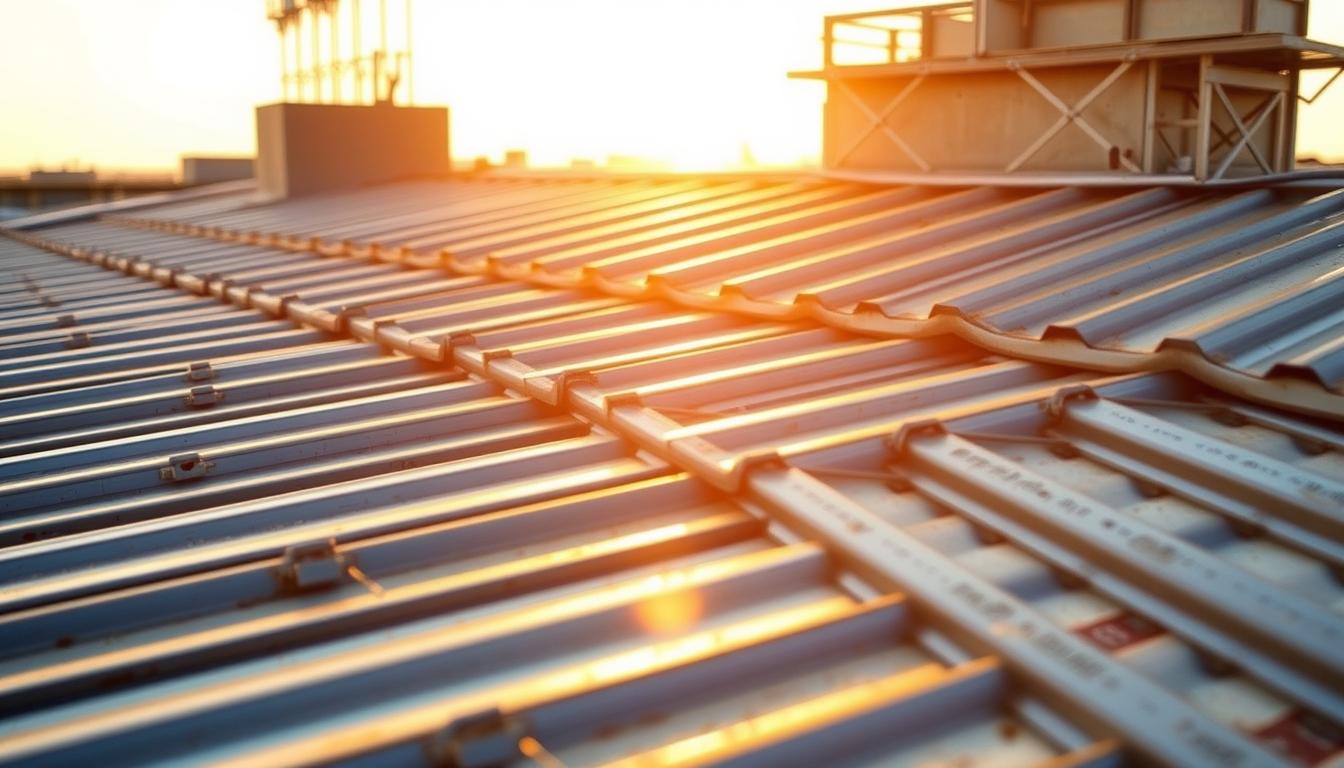

Metal profile for the roof – is an inexpensive roofing material. It is easy to transport, lightweight for installation, and requires minimal maintenance. I decided to install it on my house because it is very popular in Ukraine, especially in Lutsk.

The metal profile has many advantages. It is lightweight, very strong, and easy to install. The size of the sheets can be tailored to needs, and it comes in many colors and shapes. Additionally, it lasts a long time if installed correctly.

When installing, it is important to have metal tiles and fasteners. They help to install the metal profile correctly.

Key Points

- Metal profile for the roof – is a budget-friendly roofing material.

- The metal profile has several technological advantages, among which the low weight of the profiled sheets stands out.

- Metal tiles and roof fasteners are also important elements when installing the metal profile.

- Installing the metal profile requires special tools and techniques.

- Metal profile for the roof is a popular choice among residents of Ukraine.

- Installing the metal profile for the roof requires careful attention to each stage of installation.

Why I Choose Metal Profile for the Roof

When choosing materials for the roof, I always pay attention to pitched roofs. They provide effective water runoff and structural strength. The metal profile is very popular for roofing.

I choose it for its high strength, durability, and fire resistance. Additionally, the metal profile comes in many colors. This allows for finding the perfect option for any house.

When selecting a metal profile, I also pay attention to additional elements. For example, drainage systems and self-tapping screws. They ensure effective water runoff and maintain the integrity of the structure.

Roof insulation is also very important. It helps reduce heat loss and maintain a comfortable temperature in the house.

When choosing a metal profile, I also consider the type of roof and material. The roof pitch, battens, and waterproofing are also important. The metal profile has many advantages.

Among them are high strength, durability, fire resistance, and a variety of colors. However, one must also consider the disadvantages. These include high cost, complexity of installation, and the need for special tools.

Preparation for Installing the Metal Profile

Before starting work with the profiled sheet, preparation must be done. This includes calculating the necessary material and its delivery. It is also necessary to prepare the work area and ensure the required tools are available.

For successful roof installation, it is important to have the right tools. Among them are a drill, hammer, metal saw, batten, and string.

During preparation, it is necessary to check the strength of the roofing base. This will ensure the roof’s stability. The metal profile can be installed on various types of roofs.

Choosing roofing materials is important. For example, the thickness of the profiled sheet should be over 0.7 mm. It is also important to consider the spacing of the fasteners and the height of the eaves.

Tools I Will Need

- drill

- hammer

- metal saw

- batten

- string

Checking the Roofing Base

Checking the roofing base is important for the roof’s strength. It is important to consider the thickness of the profiled sheet and the spacing of the fasteners. After checking, installation can begin.

Choosing the Metal Profile

When choosing a metal profile for the roof, it is important to consider several factors. The metal profile is a thin metal sheet with a corrugated structure and a polymer coating. It is manufactured using cold processing. Metal tiles are also popular for roofing.

Types of Metal Profiles

The metal profile can be made from various materials. For example, steel, aluminum, zinc. The coating can vary, such as polymer, aluminum, or zinc.

Important Characteristics

The profiled sheet can be operated for 45-50 years. The thickness of the galvanized layer is 100-140 g/m². For roofing, a thickness of 0.45 – 0.50 mm is recommended.

The price of the metal profile depends on the thickness, manufacturer, and amount of zinc. The minimum price is 83 UAH, the maximum is 158 UAH. Metal tiles also have advantages, such as a long service life and corrosion resistance.

- The thickness of the metal for roofing profiled sheets ranges from 0.40 to 0.50 mm.

- The price for roofing profiled sheets starts from 179 UAH/m².

- The zinc layer under the primer can range from 80 to 300 g/m².

Measuring and Cutting the Metal Profile

When installing roof fasteners, it is important to measure and cut the metal profile. This ensures the strength and durability of the structure. It is important to consider the thickness, coating material, and color.

The metal profile can be cut with various tools. For example, a drill, metal saw, or saw. The choice of tool depends on the type of metal profile. For pitched roofs, it is better to use a saw.

Before cutting, check the roofing base. It should be strong enough for the installation of the metal profile. It is important to consider the type of roof, for example, pitched roof. For more information, visit the construction industry news site.

Installing the Metal Profile: First Stage

When installing the metal profile on the roof, it is important to consider several factors. Among them are the type of battens, material, and thickness. The metal profile can be installed on various types of battens.

For example, wooden, metal, or reinforced concrete. For durability, it is better to choose a profiled sheet with a thickness of at least 0.55 mm.

The distance between the battens for the N75 profiled sheet is 1.5-2 m. For C40, it is 0.5-0.6 m. The overlap during installation depends on the pitch angle.

To fasten the metal profile, self-tapping screws with rubber seals are used. This prevents leaking.

Metal tiles are a popular roofing material. Roof fasteners must be strong. Special fasteners are used for this.

Installing the Metal Profile: Continuation

When installing the metal profile on a pitched roof, it is important to consider several factors. Among them are the type of roof, material, pitch angle, battens, and waterproofing. To ensure strength, additional elements such as ridges and snow guards are used.

Laying the profiled sheets starts from the edge on a gable roof. On a hip roof – from the center. For large angles, it is better to use materials C-8, C-25, NS-35. The vertical overlap of the sheets should be at least 200 mm.

To fasten the sheets to the battens, self-tapping screws are used. This ensures the strength of the structure.

Roof insulation is important for energy conservation and comfort in the house. For this, special materials are installed under the metal profile. The cost depends on the sizes, pitch angle, and material.

For the longevity of the metal profile, regular inspections and repairs are needed. An annual inspection includes checking joints and the presence of scratches. Special cleaning agents with a soft brush are used for cleaning.

Waterproofing and Insulation

During roof installation, it is important not to forget about waterproofing and insulation. These are two key elements for the long life of roofing materials and comfort in the house. The waterproofing under the profiled sheet has a density of 0.04 kg/m², which helps retain water.

I use roofing materials of high strength for roof installation. Felt, roofing felt, glass mass – these are materials with good vapor permeability. They ensure the removal of warm air.

For insulation, I use materials with a low thermal conductivity coefficient. Mineral wool, foam, foil – these are materials with good vapor permeability. They prevent moisture absorption.

Waterproofing and roof insulation are important stages of installation. By using appropriate materials, I ensure a long service life for the roof and comfort. When choosing materials, I consider their technical characteristics and the spacing of the battens.

Final Touches in Installation

When installing the metal profile for the roof, I always inspect the finished structure. This helps identify defects and quickly correct them. Metal tiles and fasteners must ensure tightness and strength.

I use special tools, such as a drill and hammer, to check the fasteners. It is also important to pay attention to decorative elements. These include wind, ridge, and end strips.

Installing the metal profile requires attention to all details. This applies to the types and materials of decorative elements. It is important that the metal profile is installed on the required elements.

- Installation of the wind strip

- Installation of the end strip

- Checking for tightness

All stages must be performed with great attention. This ensures the strength and tightness of the structure. The metal profile and metal tiles must provide a long service life.

Maintenance of the Metal Profile

To ensure that the pitched roof with the metal profile lasts long, it needs regular maintenance. This means checking for damage, cleaning dirt, and checking additional details. For example, snow guards and eaves strips.

Maintenance depends on many factors. These include the type of maintenance, material, and thickness. Various tools are needed for work, such as a drill and hammer. For cleaning, water, soap, and a brush can be used. Don’t forget about roof insulation to prevent heat and moisture loss.

To properly maintain the metal profile, several tips should be followed:

- Regularly check the roof for damage.

- Clean the surface of dirt and debris.

- Check additional details, such as snow guards.

- Insulate the roof to avoid heat and moisture loss.

By following these tips, you can ensure a long service life for your roof. You will also be able to avoid heat and moisture loss.

My Experience: Tips for Beginners

My journey to installing the metal profile for the roof was challenging. But I learned from experience. Now I give advice to beginners about metal profiles and metal tiles.

Why You Shouldn’t Be Afraid to Experiment

Don’t be afraid to try new things, even if they seem difficult. Experimenting will help you find the best roof fasteners. Don’t settle for one method; seek improvements.

The Most Common Mistakes

I often made mistakes: incorrect measurements, inaccurate cuts, and poor fastening. Prepare well, check parameters twice. If problems arise, consult specialists.