An electromagnetic relay is one of the most common and important elements in electrical engineering and automated systems. It is responsible for the automatic control of electrical circuits, protection against overloads, and ensuring the reliable and safe operation of equipment.

In this article, we will take a detailed look at the purpose of an electromagnetic relay, how it works, its advantages, and areas of application. We will also provide comparative data on different types of relays and add answers to the most frequently asked questions (FAQ).

The principle of operation of an electromagnetic relay

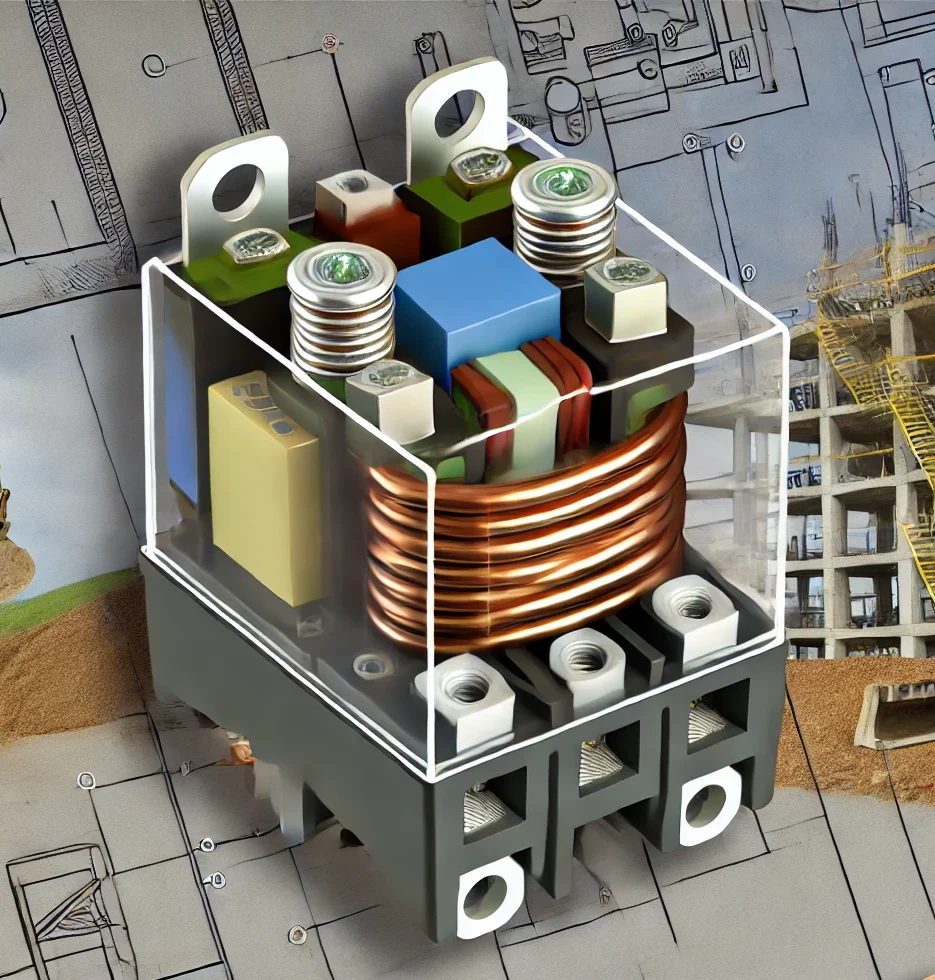

The basis of an electromagnetic relay is a coil (solenoid) that creates a magnetic field when an electric current passes through it. This magnetic field attracts or repels an armature (the moving part of the mechanism), which in turn closes or opens one or more contacts.

- Coil (winding): When current is applied, it creates a magnetic field.

- Armature: A movable metal plate that responds to the magnetic field and changes its state.

- Spring: Returns the armature to its initial position when the magnetic field disappears (current is turned off).

- Contacts: Can be normally open (NO) or normally closed (NC). Depending on the state of the armature, the contacts are either closed or open, thus controlling the electrical circuit.

Thanks to this design, what is an electromagnetic relay used for? It allows for the safe and efficient switching of high voltages and currents using a low-voltage control circuit. This provides the necessary galvanic isolation between the control circuit and the power part.

Main functions and capabilities

-

Control of electrical circuits

- Control of motors, lighting, heating systems.

- Switching between different circuits or power sources.

- Automation of processes in industry and household.

-

Protection of electrical equipment

- Protection against overloads and short circuits.

- Fault detection: if the voltage or current exceeds set limits, the relay breaks the circuit.

- Prevention of surges that can damage sensitive components.

-

Uninterruptible power supply and backup

- Automatic connection of backup power in case of an emergency in the main network.

- Timely disconnection of power in critical situations.

-

Flexibility and scalability

- Ability to adapt to different voltage and current levels.

- Availability of many types of relays with different numbers of contacts, shapes, and purposes.

Applications of electromagnetic relays in various fields

-

Industry

- Control of robotic systems, conveyors, machines.

- Protection of electric motors from overloads.

- Automation of complex technological processes.

-

Energy

- Relays are used in power distribution systems, transformer substations.

- They trigger to disconnect lines during emergencies and short circuits.

-

Automotive

- In cars, relays control lighting devices, fans, fuel pumps, power windows, etc.

- Ensure reliable operation of electrical systems under various environmental conditions.

-

Household appliances

- In washing machines, microwave ovens, air conditioners, etc., for starting and stopping motors and heating elements.

- Maintaining safety and optimal operating modes.

-

Telecommunications and IT sectors

- In uninterruptible power supply (UPS) systems, where quick switching to a backup power source is needed.

- In protecting server equipment from surges and short circuits.

Types of electromagnetic relays

Electromagnetic relays can be classified by several characteristics. Below are the most common types:

| Relay type | Features | Examples of use |

|---|---|---|

| Polarized relay | Has a permanent magnet, which changes the operating characteristics | Telecommunication equipment, low-voltage circuits |

| Non-polarized relay | Does not contain a permanent magnet, only an electromagnetic coil | General industrial applications, motor control |

| Time relay (timers) | Have a built-in mechanism (or electronics) for delaying switching on or off | Automation systems, household appliances (ventilation, heating) |

| Multi-contact relays | Can have several groups of contacts, allowing control of multiple circuits simultaneously | Complex production lines, alarm systems |

| Mini-relays (PCB relays) | Compact, designed for mounting on printed circuit boards | Electronic devices, power supplies, control modules |

| Power relay | Designed for high currents and voltages | Industrial starters, power distribution systems |

| Bistable (latching) | Retains its state after the control signal disappears (uses two coils or a magnet) | Memory systems, retaining relay state without constant current |

Each of these types has its advantages and disadvantages, so the choice of relay depends on the specific project requirements: voltage and current levels, switching speed, number of required contacts, etc.

Advantages and disadvantages of electromagnetic relays

Advantages

- Reliability: The mechanical design is simple and time-tested.

- Good insulation: Contacts and control circuit are separated, providing a high level of safety.

- Versatility: A wide range of operating parameters (voltage, current).

- Ease of maintenance: If contacts wear out, it is sufficient to replace the relay.

Disadvantages

- Mechanical wear: Contacts may oxidize or burn over time.

- Low switching speed: Compared to solid-state relays (SSR), electromagnetic relays switch more slowly.

- Noise during operation: Audible clicking when actuated.

- Increased energy consumption of the coil: Constant current is required to hold the contacts in the desired position.

Comparison of electromagnetic relays and solid-state relays (SSR)

To better understand the purpose of an electromagnetic relay compared to other types of components, let’s look at a brief comparison table of electromagnetic relays and solid-state relays (SSR).

| Characteristic | Electromagnetic relay | Solid-state relay (SSR) |

|---|---|---|

| Operating principle | Mechanical switching of contacts | Semiconductor switches (transistors, thyristors, etc.) |

| Speed | Average (limited by mechanics) | High (no mechanical moving parts) |

| Wear | There is mechanical wear of contacts | Practically absent (only thermal limitations) |

| Noise when actuated | Audible click | Practically silent |

| Isolation | Galvanic, very high | Depends on the design, usually also high |

| Price | Usually lower | Higher, especially at high currents |

| Energy loss | Small loss due to contact resistance, but energy is consumed by the coil | Depends on the type of semiconductors, may heat up |

Thus, what are electromagnetic relays used for? Primarily where versatility, reliable isolation, and cost-effectiveness are needed, and switching speed is not critically important. However, if very fast and silent switching is required, solid-state relays are sometimes chosen, although they are more expensive.

Useful tips for choosing an electromagnetic relay

- Determine the parameters: What coil voltage and maximum load current are needed?

- Pay attention to the type of contacts: NO, NC, combined, number of contacts.

- Evaluate the operating conditions: Temperature, humidity, environment, possible vibrations.

- Calculate the lifespan: The number of mechanical switches guaranteed by the manufacturer (for example, 100,000 or 1,000,000 cycles).

- Check additional features: Relay status indication, built-in protection, mounting options (DIN rail, printed circuit board).

FAQ (Frequently Asked Questions)

-

What is the purpose of an electromagnetic relay?

An electromagnetic relay is designed for automatic switching and control of electrical circuits, protecting equipment from overloads and short circuits, as well as ensuring the uninterrupted operation of systems. -

How does an electromagnetic relay differ from a solid-state relay?

The main difference is in the operating principle. An electromagnetic relay has mechanical contacts that close/open under the influence of magnetic force, while a solid-state relay (SSR) uses semiconductor elements for switching, which allows it to operate faster and silently, but it usually costs more. -

Why is overload protection important in relays?

Overloads can damage both the relay contacts and the connected equipment. The presence of protective functions helps prevent overheating, short circuits, and failure of the electrical circuit. -

Can electromagnetic relays work with different voltages?

Yes, relays are produced with coils designed for different voltage levels (for example, 5V, 12V, 24V, 220V, etc.). It is important to choose a relay with a coil suitable for your specific network or control signal. -

How to extend the lifespan of an electromagnetic relay?

- Adhere to the permissible voltage and current values.

- Avoid frequent switching at maximum loads.

- Use protective circuits (RC circuits, varistors) to reduce surges and sparks during contact breakage.

- Monitor the temperature and humidity of the environment.

-

What is an electromagnetic relay used for in everyday life?

In household appliances, relays control heating elements, electric motors, lighting, or ventilation systems. For example, in a washing machine, a relay can automatically turn the motor on and off at certain stages of washing.

Conclusion

An electromagnetic relay is one of the most effective ways to automate electrical processes and protect equipment from damage. It is reliable, relatively inexpensive, and versatile in use. Understanding its operating principle and correctly choosing the type of relay for a specific task will help ensure stable system operation and enhance the safety of electrical equipment.

If you are wondering what electromagnetic relays are used for and how to properly integrate them into your project, remember to consider the operating current, voltage, number and type of contacts, as well as operating conditions. A properly selected relay will perform its functions reliably and for a long time, minimizing the risk of failures and facilitating the automation of processes in various fields.