Insulating the attic with mineral wool is one of the most effective ways to retain heat in a house. This material combines high insulation properties, durability, and safety. Let’s take a closer look at the key advantages.

Useful videos about insulation with wool:

Video about insulation with mineral wool

Video about insulation with sheet mineral wool

Video about insulation with basalt wool

Video about attic insulation

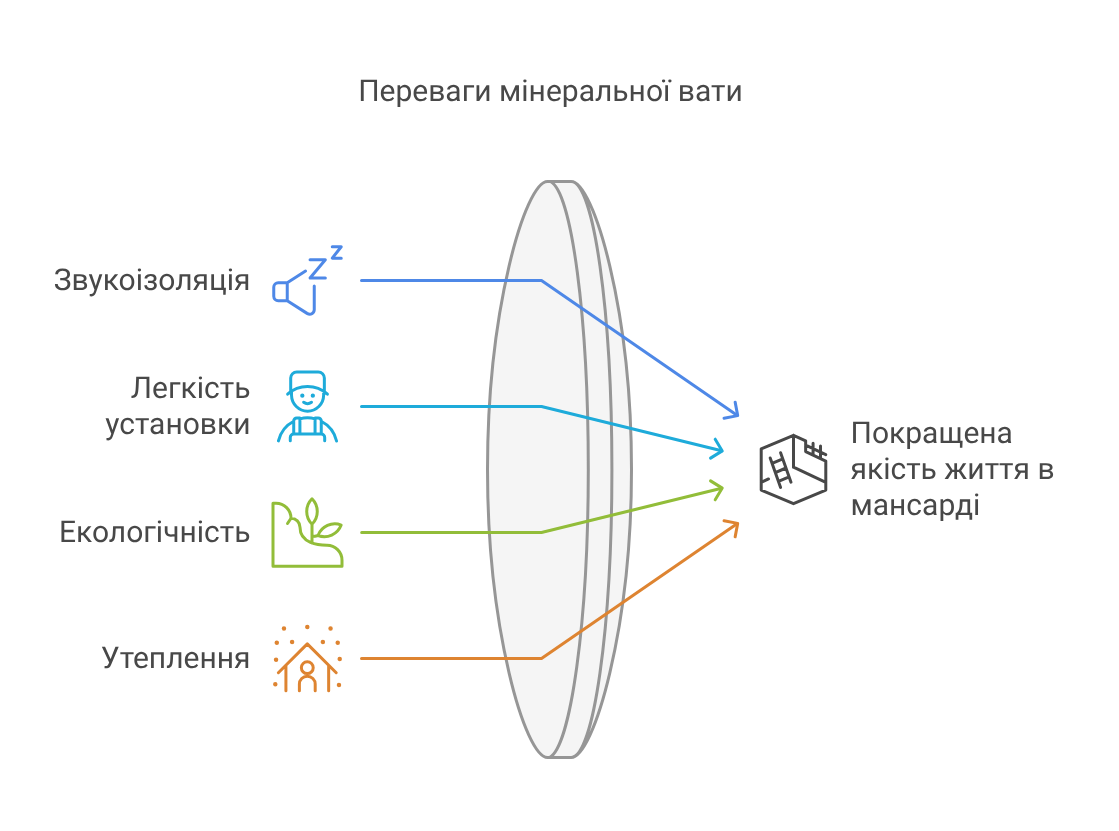

Advantages of insulation with wool

Energy efficiency

Mineral wool is one of the best thermal and sound insulation materials, with high thermal conductivity and sound absorption rates. Insulating the attic with mineral wool reduces heat loss through the roof, providing optimal comfort and energy efficiency in the rooms. Mineral wool has a low thermal conductivity coefficient, which helps retain heat in the room and prevents cold air from entering. This makes insulating the attic with mineral wool indispensable in cold climates.

Ecological safety

Mineral wool is made from natural glass fibers, making it an environmentally friendly material. Insulating the attic with mineral wool contributes to creating a healthy and safe microclimate in the room, as the material does not contain harmful substances and does not emit toxic vapors. Additionally, mineral wool is resistant to fungi and mold, ensuring durability and maintaining insulation quality over a long period.

Ease of installation

Mineral wool has a lightweight structure, which significantly simplifies installation. Insulating the attic with mineral wool is a quick and convenient process, as the material easily attaches to surfaces and does not require special equipment. Furthermore, mineral wool can be easily cut and shaped, allowing it to fit precisely into any attic shape. This ease of installation saves time and effort when insulating rooms.

All these advantages make insulating the attic with mineral wool the best option for ensuring thermal insulation and comfort in any living space. This method is economically viable and environmentally safe, as well as allowing for reduced energy costs and improved quality of life.

Inspection and assessment of attic space

The attic space is one of the most important and frequently inspected areas in a building. Its inspection and assessment allow for the identification of potential problems and ensure the safety and comfort of the residents. In this section, we will discuss the main aspects of inspecting and assessing the attic space.

1. External inspection: The first step in inspecting the attic space is an external inspection. Pay attention to the condition of the roof, ventilation openings, and other external elements. Deformations, cracks, or deficiencies may indicate possible problems inside the room.

2. Checking waterproofing: Waterproofing is an important aspect for the attic space, as it is located under the roof. Checking for the presence or damage of the waterproofing layer will help prevent moisture penetration and avoid mold and mildew formation.

3. Insulation and ventilation: Insulation is a key element for ensuring comfort and effective use of the attic space. Checking the presence and condition of insulation materials, as well as ensuring the proper functioning of the ventilation system, will help avoid energy loss and health problems.

4. Checking the electrical system: Since the attic space is usually used as a living area or office, it is important to check the condition and proper functioning of the electrical system. Identifying wiring, electrical outlets, and appliances will help prevent fires and accidents.

5. Checking the condition of walls, floors, and roof: A visual inspection of the walls, floors, and roof of the attic space is necessary to identify possible damages, cracks, and deficiencies. Such an inspection will help ensure the stability and safety of the structures.

6. Compliance with building codes: During the inspection of the attic space, it is important to ensure that all construction work is carried out according to the requirements and standards. Checking for unauthorized changes and identifying possible violations will help prevent future problems.

The process of inspecting and assessing the attic space is an important step in ensuring safety, comfort, and effective use of this area. Regular inspections and prevention of potential problems will help avoid inconveniences and maintain the value of the attic space.

Choosing the right type of mineral wool

Choosing the right type of mineral wool is an important step for effective and quality insulation of a building or structure. Mineral wool is widely used for thermal and sound insulation, as well as for fire protection. The correct choice of mineral wool depends on various factors, such as the required thickness and temperature regime, as well as the properties of the material.

Types of mineral wool

In the market segment, there are several types of mineral wool, including aerated concrete wool, ceramic wool, and slag wool. Each type has its advantages and areas of application.

- Aerated concrete wool: This type of mineral wool is widely used in the construction of walls and partitions. It is characterized by good thermal and sound insulation, as well as high fire safety. This material is often used in industrial and residential buildings where high insulation efficiency is required.

- Ceramic wool: This type of mineral wool is made from ceramics and is excellent for thermal insulation. It has high rigidity and resistance to high temperatures, making it an ideal option for insulating heating systems, steam conditioners, and other thermal engineering systems.

- Slag wool: Slag wool is made from steel production waste and has high thermal and sound insulation properties. It has high density and durability, making it suitable for insulating roofs, walls, and facades of buildings.

Determining the right type of mineral wool

When choosing the right type of mineral wool, the following factors should be considered:

- Thickness: Depending on the thermal requirements of the structure, it is necessary to choose wool with the appropriate thickness. The layer of mineral wool should be thick enough to provide effective insulation.

- Temperature regime: Different types of mineral wool have different temperature ranges in which they can function effectively. Check if the chosen type of mineral wool meets the temperature conditions of your project.

- Material properties: Each type of mineral wool has its unique properties, such as fire resistance, resistance to rodents, strength, and others. Consider these properties when choosing to meet the specific needs of your project.

The correct choice of the type of mineral wool is a key factor in achieving quality and effective insulation of a building or structure. The discussed types of mineral wool and selection factors will help you make an informed choice that meets the needs of your project.

Calculating the optimal thickness and R-value of the insulator

The optimal calculation of the thickness and R-value of the insulator is an important task when designing buildings and creating energy-efficient heating and cooling systems. These parameters determine the effectiveness and quality of insulation for walls, roofs, and floors of the building, allowing for a comfortable microclimate inside the room and reducing energy supply costs.

The thickness of the insulator is determined by calculating the optimal value that allows for the necessary level of thermal insulation. This calculation is based on indicators such as the thermal conductivity of the material, external temperature, internal temperature, and energy efficiency requirements.

The R-value of the insulator determines its resistance to heat transfer, i.e., the ability of the material to retain heat inside the room and prevent its loss to the outside. The higher the R-value, the better the insulation and the lower the heat loss.

To determine the optimal thickness of the insulator, a number of factors must be considered, including:

- Climatic conditions: external temperature, humidity, temperature changes throughout the year.

- Temperature regime of the room: internal temperature, humidity level in the room.

- Energy efficiency requirements: heat losses, energy efficiency of the building.

- Thermal conductivity of the material: characteristics of the material used as insulation.

- Orientation of the building: cardinal directions and the presence of shading objects.

The optimal thickness and R-value of the insulator are determined through mathematical calculations based on the aforementioned factors. This allows for effective thermal insulation and reduces heating and cooling costs.

It is important to note that the optimal thickness and R-value of the insulator may vary for different structures and materials. Consulting with professionals, conducting additional calculations, and tests will help ensure maximum insulation effectiveness for the building.

Calculating the optimal thickness and R-value of the insulator is an important stage in the design of any building, as properly chosen insulation ensures comfort and energy efficiency in the room. Insulators used in modern constructions have a wide range of options and characteristics, allowing for the selection of the optimal insulation variant for any conditions.

Preparing the surface for insulation

The importance of proper surface preparation before insulation

Preliminary surface preparation is a necessary step before insulating any building. This process ensures maximum effectiveness and durability of the insulation, as well as reducing the risk of any problems in the future.

Cleaning the surface

The first step in preparing the surface for insulation is cleaning it. Whether it is an old house or a new building, the surface must be free from dirt, dust, grease, and other contaminants. For this, you can use a brush, water, special cleaning agents, or high pressure. It is important to ensure complete cleaning of the surface, as any remaining dirt can negatively affect the quality of the insulation.

Repairing defects

After cleaning the surface, it is advisable to inspect for defects such as cracks, gaps, or broken parts. These defects need to be repaired before insulation begins. For this, you can use solutions or mix special repair materials.

Priming the surface

Once the surface is cleaned and defects are repaired, it is necessary to apply a primer. This step helps prepare the surface for proper adhesion with the insulator. The primer can be applied using a roller or brush. It is important to allow the primer enough time to dry.

Preparing the surface before insulation

Proper surface preparation before insulation is an important step in any construction procedure. It ensures maximum insulation effectiveness and reduces the likelihood of future problems. Cleaning the surface, repairing defects, and applying primer are steps that must be completed before insulating any house. A properly prepared surface will achieve greater thermal insulation and reduce energy costs.

Application of vapor barrier and vapor retarder

Vapor barrier and vapor retarder are two main technologies used in construction to control humidity in buildings. The vapor barrier is used to prevent the penetration of water vapor from the external environment into the room, while the vapor retarder performs the opposite process, preventing moisture from escaping from the room.

The vapor barrier is necessary at all levels of the building structure – from the foundation to the roof. The most common materials used for vapor barriers are polyethylene films and membranes. They cover the outer side of building walls and roofing structures, preventing moisture from penetrating inside the house. The vapor barrier helps retain heat in the room and avoid condensation, which can lead to mold and mildew formation.

The vapor retarder performs the opposite function – it prevents moisture from escaping from the room. It is used in buildings where it is necessary to maintain a high level of humidity. Such rooms include pools, saunas, baths, and other facilities where steam can form due to water use. The vapor retarder is often used as an internal covering for walls or ceilings, helping to maintain the stability of the building and prevent condensation formation inside.

The application of vapor barrier and vapor retarder is an important step in every construction project, as insufficient humidity control can lead to serious health problems and the quality of building structures. Additionally, the proper use of these technologies can significantly reduce the energy costs of the building and improve its energy efficiency.

These technologies can be used separately or in combination with each other, depending on the specific needs of the building. The vapor barrier and vapor retarder are important components of building systems and require proper design and execution to achieve the best results.

Note that the correct use of vapor barrier and vapor retarder is crucial for ensuring comfortable and healthy conditions in the building. Therefore, before using them, it is recommended to consult professionals who have experience and knowledge in this field.

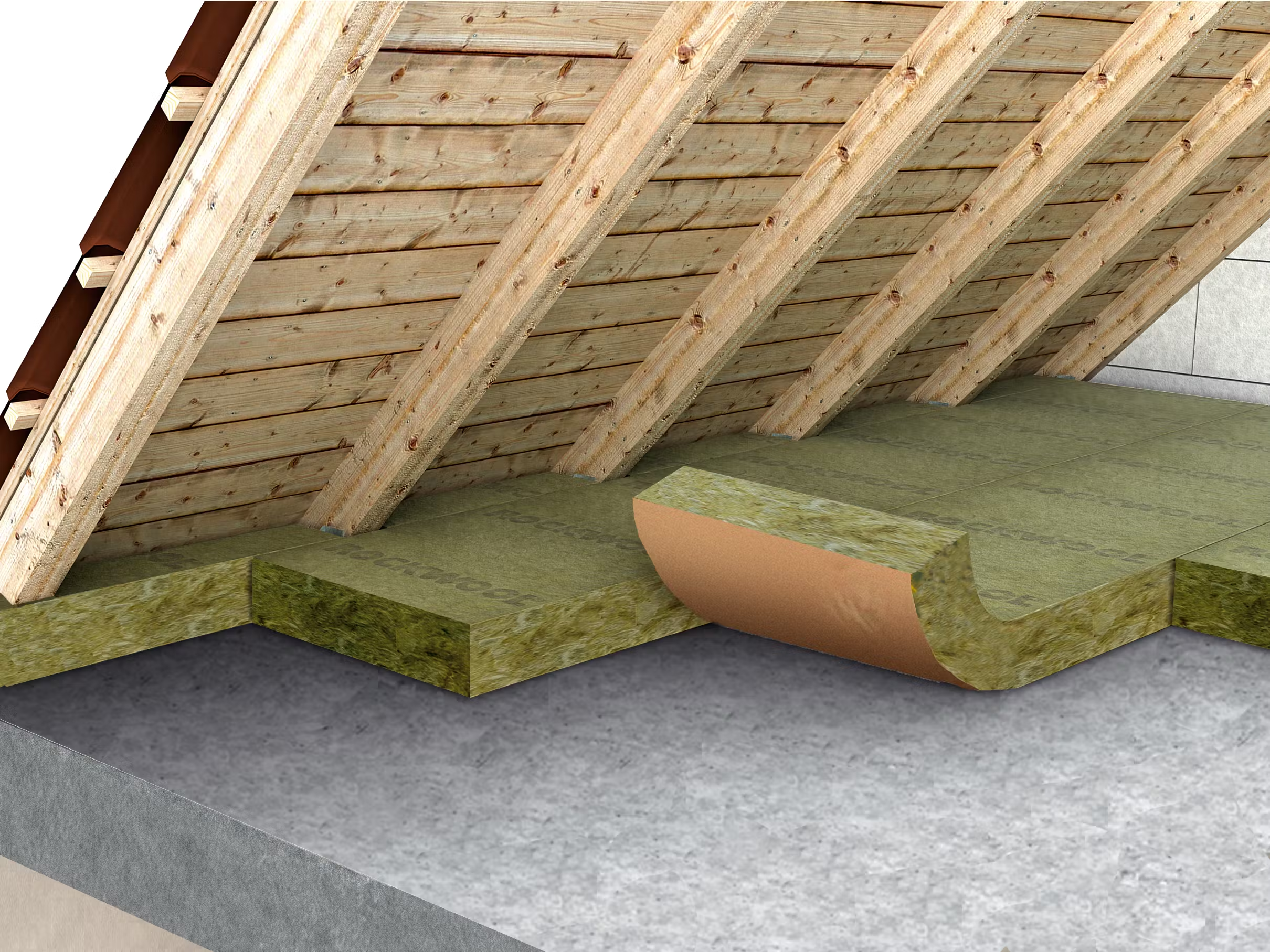

Installing mineral wool on the attic ceiling

The attic ceiling is an important component of the building structure, playing a crucial role in ensuring thermal insulation and energy conservation in the building. To achieve optimal results in these matters, installing mineral wool is one of the most effective solutions.

High thermal and sound insulation properties

Mineral wool, made from natural materials, has high thermal and sound insulation properties. This allows for effective heat retention in the room and reduces noise load. Installing mineral wool on the attic ceiling will help create a comfortable temperature and reduce noise levels in the room.

Energy conservation and cost savings

Thanks to its high thermal insulation, mineral wool allows for energy retention in the room. This helps reduce heating and cooling costs, as well as create a more energy-efficient building. Installing mineral wool on the attic ceiling allows for significant savings on heating and maintaining a comfortable microclimate in the room.

Ease of installation and durability

Mineral wool is easy to install, allowing for quick installation on the attic ceiling. Due to the special structure of the material, it does not lose its properties over a long period of use. Installing mineral wool on the attic ceiling ensures the durability of the thermal insulation covering and its effective operation over an extended time.

Insulating sloped roofs and walls of the attic

Insulating sloped roofs and walls of the attic is an important stage of construction work aimed at ensuring energy efficiency and comfort in the rooms. Proper insulation allows for reduced heating costs and retains heat in the room.

One of the key aspects when insulating sloped roofs and walls of the attic is choosing the right insulation materials. Heat retention can be achieved using materials such as mineral wool, expanded polystyrene, or polyurethane foam. It is important to choose a material that will effectively insulate the room, provide high thermal insulation, and be environmentally safe.

To achieve maximum insulation efficiency for sloped roofs and walls of the attic, a comprehensive approach is recommended. This involves combining various insulation methods, such as laying insulation materials between rafters, applying vapor barrier material, installing a ventilation system, and using thermal mass materials.

One of the key problems encountered when insulating sloped roofs and walls of the attic is the formation of condensation. This can lead to damage to insulation materials and reduce their effectiveness. To prevent condensation formation, it is advisable to install a vapor barrier layer and a ventilation system that ensures air circulation and moisture removal.

It is clear that insulating sloped roofs and walls of the attic is a very important process that affects the comfort and energy efficiency of the rooms. Choosing the right insulation materials, a comprehensive approach to insulation, and preventing condensation formation will help achieve optimal results.

Filling gaps and cracks in the attic structure

Filling gaps and cracks in the attic structure is an important stage of construction work, as it contributes to creating a solid and energy-efficient attic. Gaps and cracks in the attic structure can arise from various reasons, such as the expansion and contraction of materials due to temperature fluctuations, settling of the building foundation, improper installation of materials, or moisture penetration.

One of the main methods for filling gaps and cracks is the use of polyurethane foam. This material has the property of expanding after application, filling all irregularities and voids in the structure. Polyurethane foam also adapts well to the movements of building materials due to temperature changes, which helps avoid further cracking.

Another common method for filling is the use of sealants. Sealants, or sealing materials, are elastic and airtight substances used to fill cracks, joints, and gaps in structures. They can be waterproof, which is an important factor in preventing moisture penetration into the attic structure. Sealants can also be specifically designed for certain materials, such as wood, metal, or plastic, ensuring maximum filling efficiency.

For filling larger gaps and cracks in the attic structure, the injection pump method can be used. This method involves injecting special materials into the voids using a high-pressure pump. This allows for complete filling of the gaps, creating a strong and stable structure.

Filling gaps and cracks in the attic structure plays an important role in ensuring its durability and efficiency. The choice of filling method depends on the size and nature of the gaps and cracks, as well as the requirements for energy efficiency, airtightness, and aesthetics of the structure. The importance of properly filling gaps and cracks cannot be underestimated, as it provides the attic with maximum strength, energy efficiency, and comfortable living conditions.

Installing ventilation devices and laying ventilation ducts

Ventilation devices and ducts are necessary components of any modern ventilation system. They provide fresh air and remove contaminated air from the room, which is important for ensuring comfortable living and working conditions.

Installing ventilation devices and laying ventilation ducts requires proper planning and execution. The installation process must be well-organized and comply with all standards and requirements. It is important to consider the needs of the room, the sizes and characteristics of the ventilation devices, as well as the optimal placement of the ducts.

Before installing ventilation devices, a detailed analysis of the room should be conducted. It is advisable to pay attention to factors such as the area of the room, the number of people present, types of emitted pollutants, and the presence of odor sources or harmful substances. This information will help determine the power and number of ventilation devices, as well as the optimal placement of the ducts.

An important stage is the correct choice of ventilation devices that meet the needs of the room. It is necessary to consider factors such as performance, noise load, energy efficiency, and the ability to adjust operating modes. It is also important to pay attention to the quality of the ventilation devices and their compliance with safety standards.

After selecting the ventilation devices, the proper laying of the ducts must be carried out. This process includes determining the optimal route for laying the ducts, considering the building structure, installation accessibility, and effective air distribution. It is also important to comply with all technical regulations and normative acts governing ventilation systems.

The final stage is the adjustment and testing of the installed system. It is important to ensure that the ventilation devices are functioning properly and that the ducts provide the required performance and air distribution. During the adjustment, possible malfunctions or deficiencies in the system may be identified and corrected.

Installing ventilation devices and laying ventilation ducts is an important aspect of creating comfortable and safe conditions in buildings. Adhering to the rules and standards in these processes ensures the effectiveness and reliability of the ventilation system.

Protection against condensation and moisture formation

One of the key aspects of ensuring comfortable conditions in a room is protection against condensation and moisture formation. High humidity can lead to moisture accumulation on surfaces, which can result in mold, mildew, and other undesirable consequences.

The first step in ensuring protection against condensation is proper insulation coverage. Quality insulation of building structures, such as walls and roofs, helps retain heat inside the building and avoid condensation on cold surfaces. It is also important to ensure that insulation materials are properly installed and provide airtightness for the building.

An additional effective means of protection against condensation is the use of ventilation systems. Powerful ventilation systems ensure air circulation within the building, removing moisture and bringing fresh air into the room when necessary. This helps avoid moisture stagnation and maintains optimal humidity in the room.

In addition, it is also necessary to ensure proper insulation of pipes and air conditioners, which can be sources of condensation formation. Quality thermal insulation materials help avoid heat transfer to the surface, ensuring its absence or significantly reducing the risk of condensation formation.

It is also important to monitor the condition of the internal and external surfaces of the building. Regular inspections help identify potential problems, such as leaks due to physical defects, which can lead to condensation formation. Timely resolution of such issues helps maintain optimal moisture conditions and provides additional protection against condensation and moisture formation.

A comprehensive approach to protection against condensation and moisture formation includes proper insulation, ventilation, insulation, and regular inspection and maintenance of the building. Only through such an approach can comfortable conditions be ensured and prevent negative consequences associated with condensation and moisture formation.

Using insulation materials in the facade finishing of the attic

In modern conditions, when energy efficiency is becoming an increasing concern, the use of insulation materials in the facade finishing of the attic is gaining more relevance. What exactly can be understood by the term “insulation materials”? What are their main types and properties? How do they affect heat retention in the living space of the attic? This section of the article is dedicated to answering these questions.

Insulation materials are special materials designed to retain heat in buildings and prevent its loss through walls, floors, ceilings, and other elements of building structures. The use of insulation materials in the facade finishing of the attic is one of the ways to enhance heat retention and reduce heating costs.

The most common types of insulation materials:

- Mineral wool – made from cut and compressed basalt or glass wool, providing high thermal insulation capacity and mechanical strength.

- Extruded polystyrene (XPS) – has low thermal conductivity, high vapor permeability, and resistance to water absorption, making it an effective material for insulating attics.

- Polyurethane foam – has a high thermal insulation coefficient and is a flexible material that allows for easy processing of any attic shape.

- Extruded polyethylene foam (XPE) – has low weight, good thermal insulation, and vapor permeability, providing effective insulation of the attic from temperature fluctuations.

The use of insulation materials in the facade finishing of the attic can have several advantages:

- Reduction of heat loss and increased comfort in the room.

- Decreased energy consumption and ecological well-being.

- Increased heating efficiency and reduced heating costs.

- Protection against atmospheric influences and pollution.

Considering the above, the use of insulation materials in the facade finishing of the attic is a necessary step in creating energy-efficient and comfortable spaces. When choosing an insulation material, it is important to pay attention to its technical characteristics and strength, as well as to ensure proper installation technology and secure fixation of materials on the facade of the attic.

Sound insulation of the attic using mineral wool

Sound insulation is an important component of the construction process, especially when equipping attics. The attic, being the top floor of the building, has specific features when it comes to sound insulation, but it can be effectively achieved using mineral wool.

Mineral wool is a material made from glass or stone wool, used for insulation and soundproofing buildings. This material has several advantages that make it an ideal choice for sound insulation of attics:

- High sound insulation: Mineral wool has excellent sound insulation properties that effectively reduce sound transmission. This is especially important for attics, where there may be noise from the street, rain, or ventilation systems.

- Ease of installation: Mineral wool is lightweight and convenient to install. It can be placed in the gap between the attic ceiling and the floor of one of the lower rooms. This process can be done quickly and safely, saving time and effort.

- Environmental safety: Mineral wool is made from sterilized material, making it safe for health and the environment. It does not contain harmful substances or toxic elements that can affect air quality in the rooms.

- Insulation: In addition to sound insulation, mineral wool also helps insulate the attic, retaining heat in the room during winter and reducing heating costs. This can be especially important for attics located in old buildings or in cold regions.

Overall, mineral wool is one of the most effective materials for sound insulation of attics. It not only provides the necessary level of sound insulation but also has other useful properties that make it an indispensable material for construction. Sound insulation of the attic using mineral wool is an important step in creating a comfortable and quiet space in your home.

Insulating the floor and ceiling at the attic level

Insulating the floor and ceiling at the attic level is one of the most important stages of energy-efficient construction and home renovation. Effective insulation of these elements allows for the elimination of heat loss, improving comfort in the room and reducing energy costs.

Before insulating the floor and ceiling at the attic level, a detailed analysis of the building’s condition must be performed. This includes checking for thermal bridges, damages, and cracks, as well as assessing the level of insulation already installed.

When insulating the floor, it is advisable to use materials with high thermal insulation properties, such as extruded polystyrene or mineral wool. They provide optimal thermal insulation and prevent cold from penetrating from the lower floors into the living space.

For insulating the ceiling at the attic level, insulators such as mineral wool or extruded polystyrene can be used, which are easy to install between rafters or under the roof floor. This helps retain heat in the room and prevents overheating in winter and overheating in summer.

One step closer to an energy-efficient building: insulating the floor and ceiling at the attic level allows for reduced energy consumption and heating costs, positively impacting long-term economic efficiency and ecology. With proper insulation of the house, comfort can be increased without enlarging the heating system.

All these measures for insulating the floor and ceiling at the attic level achieve improved energy efficiency of the building. This is an important aspect of modern construction, considering the rising cost of energy resources and the need to preserve the environment.

Insulating the floor and ceiling at the attic level addresses the problem of heat loss and ensures comfortable living in the house. It is an effective way to reduce energy costs and improve quality of life. It is important to choose the right materials and perform the work professionally to ensure maximum thermal insulation and efficiency of the building.

Control and evaluation of the quality of attic insulation

Insulating the attic is an important stage of renovation work to ensure a comfortable climate in the room and reduce heating costs. However, improperly performed insulation work can lead to significant energy losses and deteriorate the quality of life in the house. Therefore, control and evaluation of the quality of attic insulation are necessary steps to ensure the effectiveness and durability of the insulation.

Evaluation of the quality of attic insulation

The first step in evaluating the quality of attic insulation is checking the correctness of the choice and installation of insulation material. The choice of material for insulating the attic should consider factors such as thermal conductivity, hypoallergenicity, environmental safety, and durability.

The next important step is checking the correctness of the installation of the insulating material. Ensure that the material is evenly distributed, without gaps, and tightly adheres to all surfaces. Pay attention to the joints and connections to other structures – they should be well-sealed and airtight.

Next, conduct thermal measurements to assess the effectiveness of the insulation. Use a thermal imager or thermal camera to identify cold spots and areas where heat is lost the most. This will help identify possible insulation problems and take necessary measures to address them.

Quality control of attic insulation

One of the main elements of quality control of attic insulation is monitoring the work during its execution. Ensure the presence of a qualified specialist who will monitor the correctness of the installation of insulation material and the execution of all necessary work.

It is also important to conduct regular inspections of the attic after the insulation work is completed. Ensure that the insulation material is not damaged, and that there are no cracks or external damages. If necessary, carry out the necessary repair work to ensure the durability of the insulation.

Energy efficiency and economic advantages of insulating the attic with mineral wool

Insulating the attic is an important component of energy-efficient construction and improves the thermal insulation of rooms located under the roof. One of the convenient and effective materials for insulating the attic is mineral wool, which has several undeniable advantages.

First of all, the use of mineral wool for insulating the attic contributes to significant energy resource savings. Houses that lack proper thermal insulation lose a lot of heat through the roof. Thanks to the properties of mineral wool, which is a highly effective thermal insulation material, heat can be retained inside the house, reducing heating and cooling costs.

The use of mineral wool for insulating the attic also has economic advantages. Compared to other materials, such as foam or polystyrene, mineral wool is more affordable and cost-effective. Additionally, mineral wool has a long service life, ensuring savings on repeated repair work or material replacement due to loss of effectiveness.

Insulating the attic with mineral wool also contributes to improving the ecological condition. Mineral wool is made from renewable resources and does not contain harmful substances, making it safe for human health and the environment. Furthermore, using mineral wool reduces energy consumption produced by polluting sources such as coal or oil.

Thus, insulating the attic with mineral wool not only improves the energy efficiency of buildings but also has numerous economic advantages. The use of this material allows for reduced heating and cooling costs, conserving energy resources, ensuring the durability of buildings, and improving ecological sustainability.

Frequently asked questions about attic insulation (FAQ)

Insulating the attic is an important stage of construction or renovation that affects the comfort and energy efficiency of housing. One of the best materials for this is mineral wool. In this section, you will find answers to key questions regarding effective attic insulation.

1. What is mineral wool and how does it work?

Mineral wool is an insulation material made from melted glass or stone. Due to its low thermal conductivity, it creates an air barrier that prevents heat loss through the walls, roof, and floor of the attic.

Main properties of mineral wool:

✔ High thermal insulation – reduces heating costs.

✔ Sound insulation – helps protect against external noise.

✔ Fire safety – does not burn and does not support combustion.

2. What are the advantages of insulating the attic with mineral wool?

✅ Energy savings – reduces heat loss and saves money on heating.

✅ Comfort in any season – helps retain heat in winter and coolness in summer.

✅ Moisture resistance – the material does not absorb moisture if installed correctly.

✅ Durability – retains its properties for decades.

3. How to properly insulate the attic with mineral wool?

Step 1: Surface preparation

- Remove old insulation, if any.

- Clean the surface of dust and construction debris.

- Check for cracks or damages in the structure and repair if necessary.

Step 2: Material selection

- Choose mineral wool according to the required density and thickness.

- For attics, mineral wool with a thickness of at least 150 mm is usually used.

Step 3: Installing the insulator

- Lay the wool tightly between the rafters, without gaps.

- Add a second layer of insulation perpendicular to the first for better thermal insulation.

- Cover the insulation with a vapor barrier film to prevent moisture accumulation.

4. What methods are there for insulating the attic with mineral wool?

🔹 Floor insulation – reduces heat loss through the ceiling.

🔹 Wall insulation – provides a uniform temperature regime in the attic.

🔹 Roof insulation – prevents heat leakage through the roof.

For maximum insulation efficiency, it is advisable to combine these methods.

5. What safety measures should be followed when working with mineral wool?

🔸 Use protective goggles, a mask, and gloves to avoid skin and respiratory irritation.

🔸 Work in a well-ventilated area.

🔸 Follow the manufacturer’s recommendations for installation and storage of the material.