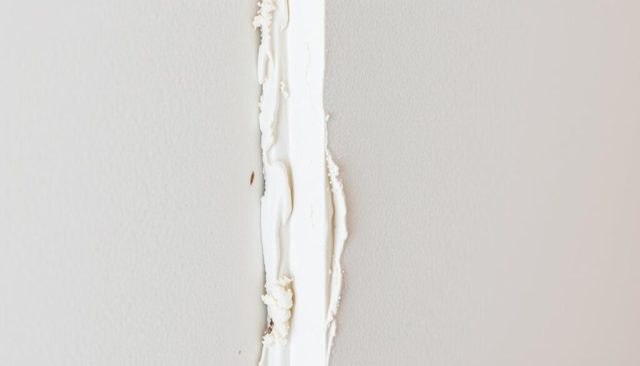

Gypsum board is a popular material for wall and ceiling cladding, but its porous structure requires careful leveling. The choice of the right putty determines the final result of the renovation. An incorrectly selected putty can lead to cracks, peeling, and uneven painting.

The modern market offers a wide range of putties from well-known brands such as Sniezka, Knauf, Ferozit, ALBA, BauGut, and others. Each of these brands has its own features, so it is important to consider the characteristics of the material, such as adhesion, elasticity, and water resistance.

Gypsum putty is suitable for indoor work, while polymer or cement-based putty is better for wet areas. Price also plays an important role, but it does not always mean higher quality. To avoid making a mistake in your choice, you need to consider the specifics of the room and the type of surface.

Main Points

- The choice of putty depends on the type of surface and the conditions of the room.

- Gypsum putty is suitable for indoor work, while polymer putty is for wet areas.

- Price does not always correspond to quality – it is important to consider the characteristics of the material.

- Well-known brands guarantee high quality products.

- To avoid cracks, it is important to consider the elasticity and adhesion of the putty.

Overview of Putty Assortment for Gypsum Board

The modern market offers a large selection of putties specifically designed for working with gypsum board. Each product has its own features, making it suitable for specific tasks.

Popular Brands and Products

Among the most popular brands, Sniezka ACRYL-PUTZ ST10 and Knauf FUGENFULLER stand out. These products are known for their high quality and effectiveness in sealing joints and leveling surfaces.

These models are often recommended by professionals for their ease of use and high adhesion. For example, Sniezka ACRYL-PUTZ ST10 is ideal for indoor work, while Knauf FUGENFULLER is known for its stability in high humidity conditions.

Characteristics and Features of Mixtures

Each mixture has its own characteristics, such as adhesion strength, elasticity, and drying time. For instance, acrylic mixes are known for their flexibility, while cement-based ones offer higher moisture resistance.

When choosing a product, it’s important to consider the specific conditions of the room. For dry areas, gypsum-based mixes are more suitable, while for bathrooms or kitchens, it’s better to opt for polymer or cement-based options.

Water-dispersible putties, such as Sniezka ACRYL-PUTZ ST10, have high elasticity, which prevents the appearance of cracks. Cement mixtures, such as Knauf FUGENFULLER, are ideal for rooms with increased humidity.

Additionally, it is important to consider customer reviews. Many users note that products from well-known brands, such as Sniezka and Knauf, have high quality and durability.

Joint putties for gypsum board should not only level the surface but also ensure the strength of the joints. By choosing quality material, you ensure that your work will be long-lasting and reliable.

Advantages of Using Specialized Putty

Specialized putties for gypsum board offer numerous advantages that make them indispensable in construction work. Due to their high quality and specific characteristics, they ensure durability and aesthetics of surfaces.

Ease of Application and Quick Drying

One of the main advantages of specialized putties is their easy application. Mixtures such as Sniezka ACRYL-PUTZ and Ferozit are designed with the needs of professionals in mind, making work easier and reducing time costs. The quick drying time allows for the rapid continuation of repair work without waiting for a long time.

For example, Sniezka ACRYL-PUTZ ST10 has high elasticity, which prevents cracks, while Ferozit is known for its stability in high humidity conditions. This makes them an ideal choice for various room conditions.

High Adhesion and Durability

High adhesion is a key factor that affects the durability of treated surfaces. Specialized putties provide a strong bond with gypsum board, reducing the risk of peeling and cracks. Practical examples using these mixtures demonstrate their effectiveness and durability.

For instance, cement putties, such as Knauf FUGENFULLER, are ideal for rooms with increased humidity. They provide high strength and stability, making them a popular choice among professionals.

| Type of Putty | Features | Drying Time | Good for |

|---|---|---|---|

| Gypsum | High elasticity, ease of application | 15-30 min | Indoor work |

| Polymer | Water resistance, elasticity | 30 min – 1 hr | Wet areas |

| Cement | High strength, stability | 1-2 hrs | Long-lasting structures |

Reviews from professionals confirm that using specialized putties allows achieving high quality work and durability. By choosing quality material, you ensure peace of mind and guarantee long-term operation of surfaces.

Putty for Gypsum Board

Putty for gypsum board is an important element in construction work that ensures smoothness, strength, and durability of the surface. Its use allows achieving an ideal result, eliminating unevenness and cracks.

Specialized putty for gypsum board joints has several important functions. First, it fills the gaps between gypsum board sheets, ensuring surface uniformity. Second, it enhances the strength of the joints, preventing their peeling. Finally, it creates an ideal base for further finishing.

To achieve the best result, it is important to consider several technological nuances. For example, before applying the putty, it is necessary to reinforce the joints using special tapes. This can be paper, mesh fiberglass, or self-adhesive tape. Each type has its advantages, but all provide additional strength to the joints.

Another important step is the use of primers. Priming improves the adhesion of the putty to the gypsum board surface, contributing to long-term operation. It also reduces moisture absorption, which is important for the stability of the putty.

Putty for gypsum board should have a consistency similar to thick sour cream. This ensures easy application and the ability to achieve a uniform surface. After application, each layer should dry for 5-6 hours, allowing work to continue without significant delays.

It is important to emphasize that the correct choice of mixture affects the quality of the gypsum board joints. Specialized putties, such as Sniezka ACRYL-PUTZ ST10 or Knauf FUGENFULLER, have high elasticity and adhesion, making them an ideal choice for various room conditions.

Thus, using quality putty for gypsum board in combination with the correct application technology allows achieving high surface quality, which is important for further finishing. By choosing quality material, you ensure peace of mind and guarantee long-term operation of surfaces.

Tips for Choosing Quality Putty

Choosing the right putty is an important step in ensuring a long-lasting and aesthetic surface for gypsum board. To avoid mistakes, it is worth considering several key factors.

How to Evaluate Material Characteristics

First of all, pay attention to indicators such as adhesion, elasticity, and wear resistance. For example, polymer putties have high elasticity, which prevents cracks. Cement mixtures are ideal for wet areas.

Drying time also plays an important role. Gypsum putties dry faster, while cement ones may take up to 24 hours.

User Reviews and Professionals’ Experience

Professionals often recommend brands such as Sniezka and Knauf for their high quality and ease of use. For example, Sniezka ACRYL-PUTZ ST10 is known for its elasticity, which prevents cracks.

Additionally, it is important to consider reviews about drawbacks, such as putty rolling or long drying times. This will help choose the material that best suits your conditions.

To avoid mistakes, pay attention to the proper evaluation of the product before purchase. Choosing quality putty guarantees long-term operation of surfaces and your peace of mind.

Technology of Preparing and Applying Putty

Surface preparation is the first and most important step in working with putty. Cleanliness and dryness of the surface will ensure strong adhesion of the mixture to the gypsum board. Before starting work, the presence of dust, grease, or moisture that may affect the quality of application is excluded.

Surface Preparation and Application of Primer

For better adhesion of the putty, primer is used. It improves the contact between the gypsum board and the putty, reducing the risk of peeling. The primer is applied evenly over the entire surface using a roller or brush.

To achieve an even distribution of the mixture, various types of spatulas are used. A thin layer is applied first, and after it dries, the next layer is applied. It is important to control the drying time, which can vary from 15 minutes to several hours depending on the type of putty.

After applying the putty, sanding is performed to achieve ideal smoothness. This is an important step for further finishing of the surface.

- Cleanliness and dryness of the surface are the basis for quality application.

- Primer improves the adhesion of the putty to the gypsum board.

- Spatulas and rollers are the main tools for application.

- Sanding after the putty dries prevents unevenness.

Monitoring the drying time of the putty allows avoiding premature application of the next layer. For better results, use quality tools and follow technological recommendations.

Features of Working with Putty for Gypsum Board Joints

Putty for gypsum board joints is an important element that determines the strength and smoothness of the surface. Its proper application and preparation of the joints prevent cracks and ensure long-term operation.

Reinforcing Joints and Preparing Joints

Before applying the putty, it is necessary to reinforce the joints using special tapes. This can be paper, mesh, or self-adhesive tape. Reinforcement enhances the strength of the joints and prevents their peeling.

Preparing the joints includes applying putty, which should have a consistency similar to thick sour cream. This allows for easy application and achieving a uniform surface. After application, each layer should dry for 5-6 hours.

Proper Application and Sanding

To achieve the perfect result, it is important to consider technological nuances. The application of putty should be even, and sanding should be done after complete drying. This ensures surface smoothness and prevents unevenness.

The drying time of the putty is calculated so that the professional can correct any imperfections. The fine-grained structure of the putty allows achieving a glossy surface after sanding.

- Reinforcing joints with tape prevents cracks.

- Putty is applied in even layers.

- Sanding is done after complete drying.

- Drying time is determined by the type of putty.

To avoid mistakes, it is worth considering the recommendations of manufacturers, such as Knauf, which guarantee quality results. Using specialized putties allows achieving high surface quality.

Comparison of Leading Manufacturers and Price Analysis

When choosing putty for gypsum board joints, not only quality but also price plays an important role. The market offers various brands that provide products with different characteristics.

For example, Knauf and Sniezka are leaders among manufacturers. Knauf offers products with high strength and stability, suitable for wet areas. Sniezka, in turn, is known for its elasticity, which prevents cracks.

| Brand | Price (UAH) | Advantages | Disadvantages |

|---|---|---|---|

| Knauf | 80-150 | High strength, stability in humid conditions | Longer drying time |

| Sniezka | 70-140 | High elasticity, quick application | Limited water resistance |

| Ferozit | 60-130 | Well-suited for indoor work | Low stability in high humidity |

Additionally, when choosing a product, it is important to consider user reviews and characteristics such as adhesion, drying time, and uniformity of the mixture. Specialized mixtures offer more advantages, higher adhesion, and elasticity.

Conclusion

Putty for gypsum board is an important element that determines the quality and durability of the surface. Choosing the right product and its proper application is crucial for achieving the perfect result.

Particularly important is the correct approach to working with the joint of gypsum board. Specialized putties offer numerous advantages, including high elasticity, strength of joints, and quick drying. This helps avoid cracks and unevenness, providing a smooth and reliable surface.

When it comes to price, it is important to consider that low cost does not always mean quality. When choosing putty, pay attention to its characteristics, such as adhesion, elasticity, and water resistance. This will help achieve better results and prevent problems in the future.

To avoid mistakes in your choice, familiarize yourself with user reviews and technical specifications of products. This will help determine which product is best suited for your needs.

In conclusion, it is important to emphasize that careful selection of materials and the correct technology of work are guarantees of successful renovation. Invest in quality putties, and your work will bring you joy and comfort for many years to come!