Construction reinforcement is very important for modern construction. It provides strength and stability to buildings. Metal rods for concrete help strengthen reinforced concrete elements.

When choosing reinforcement, it is important to think about the durability of the building. The right choice of metal rods for concrete helps the structure withstand loads.

In this article, we will talk about construction reinforcement. You will learn about its types, characteristics, and use in construction.

Key Findings

- Reinforcement is an indispensable element of reinforced concrete structures

- The right choice of reinforcement increases the strength of structures

- There are different classes and types of reinforcement materials

- Compliance with technical standards during installation is critically important

- The quality of reinforcement affects the durability of construction objects

What is construction reinforcement?

Reinforcement is a key element in construction. It provides strength and stability to reinforced concrete structures. Steel reinforcement helps concrete withstand large loads.

Definition of the term

Reinforcement bars are metal rods for reinforcing concrete. They strengthen concrete by withstanding tensile forces. This increases the strength of structures.

Main types of reinforcement

- Working reinforcement – perceives the main loads

- Distribution reinforcement – evenly distributes loads

- Installation reinforcement – ensures the fixation of structures

Purpose of reinforcement in construction

Steel reinforcement performs several important functions:

- Increasing the strength of concrete structures

- Ensuring stability to loads

- Preventing the destruction of structures

Interesting fact: Reinforcement can withstand tensile loads 10 times greater than ordinary concrete.

What types of reinforcement exist?

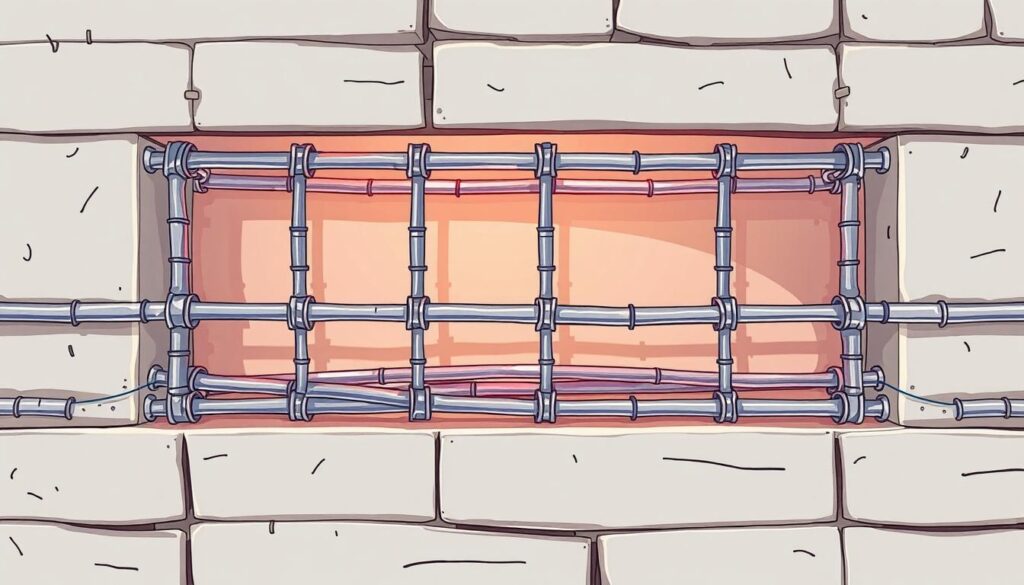

There are many types of reinforcement in construction. They are divided into several groups. Reinforcement frames and meshes are important for the strength of buildings.

Classification by shape

Types of reinforcement differ in shape:

- Bar reinforcement – the most common type

- Wire reinforcement

- Profiled reinforcement

- Reinforcement meshes

- Spatial frames

Classification by material

Reinforcement can be classified by material:

- Steel reinforcement – the most widespread

- Composite reinforcement

- Basalt reinforcement

- Fiberglass reinforcement

Classification by manufacturing method

Reinforcement frames are manufactured in various ways:

- Hot-rolled reinforcement

- Cold-drawn reinforcement

- Welded reinforcement

Each type of reinforcement has its own characteristics. For example, steel reinforcement retains its properties for many years. Basalt reinforcement does not rust and is moisture resistant.

How to choose reinforcement for your building?

The right choice of reinforcement is very important for the success of construction. The quality of reinforcement ties affects the strength and durability of the structure.

Assessing project needs

When choosing reinforcement, several criteria should be considered:

- Type of building

- Expected load

- Operating conditions

- Climate features of the region

Material quality requirements

Reinforcement anchorage must ensure a strong connection with concrete. The main characteristics of quality reinforcement are:

- High strength

- Plasticity

- Corrosion resistance

- Thermal endurance

Supplier recommendations

When choosing a reinforcement supplier, pay attention to:

- Availability of certificates

- Market reputation

- Warranty conditions

- Range of reinforcement diameters

Remember: quality reinforcement ties are the key to the reliability of the entire structure!

Rules for storing reinforcement

Proper storage of reinforcement rods is very important. It helps maintain quality and durability on construction sites. Properly storing reinforcement means ensuring the reliability of future buildings.

Main storage conditions

Reinforcement, especially anchor bolts, requires special handling in storage. The main requirements are:

- Protection from atmospheric influences

- Humidity control (not above 60%)

- Temperature range from 12 to 16°C

Preventing corrosion of reinforcement rods

Corrosion can significantly reduce the strength of reinforcement. Experts recommend using special anti-corrosion coatings and adhering to storage rules.

“Proper storage of reinforcement is the key to the reliability of future structures”

Organizing storage facilities

When storing reinforcement rods, it is important to follow the rules:

- Minimum distance between stacks – 1 meter

- Storage in a horizontal position

- Separation by types and sizes

- Using pads for ventilation

Following these recommendations ensures the preservation of the quality of anchor bolts and reinforcement rods for a long time.

Application of reinforcement in reinforced concrete structures

Metal rods for concrete are very important for creating strong reinforced concrete structures. They help buildings be strong and stable. This ensures their durability.

Features of reinforcement installation

The installation of metal rods for concrete includes several important steps:

- Thorough surface preparation

- Precise installation of reinforcement frames

- Adhering to project distances

- Reliable fastening of connections

Placement recommendations

When placing reinforcement frames, several principles should be followed:

- Ensure a minimum protective layer of concrete

- Maintain specified project distances between rods

- Avoid mechanical damage during installation

Load calculation

In Ukraine, the nominal diameter range of reinforcement products varies from 4.0 to 50.0 mm. The choice of the correct diameter of metal rods for concrete depends on the expected load and type of structure.

The standard DSTU 3760:2019 regulates the technical requirements for steel reinforcement, including smooth and periodic profile products.

Reinforcement frames must be calculated taking into account:

- Static loads

- Dynamic impacts

- Climate conditions

- Specifics of the construction object

Quality requirements for reinforcement

The best quality of steel reinforcement is important for the safety of buildings. Reinforcement bars must meet high standards. They must also be carefully controlled.

Standards and regulations

In Ukraine, there are important standards for reinforcement:

- DSTU 3760:2019 (for reinforcement with a diameter of 5.5-40 mm)

- DSTU 9130:2021 (for reinforcement with a diameter of 6-80 mm)

Testing and quality control

Quality control of reinforcement includes several stages:

- Raw material quality control

- Operational control

- Material strength testing

- Testing upon delivery of finished products

Certification

Certification of reinforcement bars includes checking their properties. For example, class A500C has the following characteristics:

| Parameter | Value |

|---|---|

| Minimum strength limit | ≥ 500 MPa |

| Reliability coefficient | 1.15 |

| Calculated resistance | 435-450 MPa |

Certified A500C reinforcement reduces metal costs. Without loss of quality.

The choice and quality control of reinforcement are important for the safety of buildings.

Reinforcement manufacturing technologies

Reinforcement production is a complex process. It requires high precision and professional skills. Modern technologies help create quality reinforcement meshes and ties.

The main stages of reinforcement production include several key phases:

- Raw material preparation

- Metal melting

- Hot rolling

- Heat treatment

- Cooling and forming

Innovative production methods

Modern technologies allow the creation of reinforcement meshes with increased strength. Thermomechanical treatment of steel improves the mechanical properties of reinforcement.

Environmental aspects of production

Reinforcement tie manufacturers are increasingly paying attention to ecology. They use technologies that:

- Reduce CO2 emissions

- Recycle metal waste

- Use energy-efficient equipment

| Reinforcement class | Tensile strength | Features |

|---|---|---|

| A240C | 240 MPa | Smooth reinforcement |

| A400C | 400 MPa | Ribbed reinforcement |

| A500C | 500 MPa | Thermomechanically treated |

Reinforcement and its role in the strength of structures

Modern construction cannot be imagined without reliable solutions. Reinforcement is important for the strength of buildings.

Mechanism of reinforcement impact on strength

Reinforcement connects with concrete, creating a strong structure. Steel rods withstand large loads, even more than concrete.

- Reinforcement of structures in tension

- Increased deformation resistance

- Prevention of crack formation

Comparison with alternative materials

Reinforcement is better than other materials:

| Material | Strength | Cost |

|---|---|---|

| Ordinary concrete | Low | Low |

| Reinforcement | High | Medium |

| Composite materials | Medium | High |

Research and statistics

Scientific research shows the importance of reinforcement. Modern reinforcement technologies create structures capable of withstanding large loads.

“Reinforcement is the heart of a reinforced concrete structure, ensuring its reliability and durability”

Use of reinforcement in various areas of construction

Construction reinforcement is very important for building. It helps create strong structures. It can be used in residential, industrial, and infrastructure construction.

Residential construction

In private construction, construction reinforcement ensures the strength of structures. Statistics show that 80% of foundations in the private sector are reinforced with steel. This ensures the stability and safety of houses.

Industrial facilities

In the industrial sector, composite reinforcement is increasingly used. Its popularity is growing due to its lightness and corrosion resistance. This is very important for complex production environments.

Infrastructure projects

Infrastructure projects, such as bridges and roads, actively apply new reinforcement technologies. 50% of bridges use composite reinforcement to reduce weight. And a 40% increase in demand for reinforcement is observed specifically in road construction.