In modern construction and renovation works, the correct choice of concrete proportions is the key to the strength, stability, and durability of structures. Whether you are building a foundation, wall, slab, or another element, adhering to precise proportions of components allows you to achieve optimal material characteristics, avoid defects, and reduce costs. In this article, we will examine the main components of concrete, the factors influencing their selection, and a step-by-step method for calculating concrete proportions with a practical example.

1. Main components of concrete

Concrete consists of four main components:

- Cement: Acts as a binding element. The quality of cement directly affects the strength and durability of concrete.

- Sand: Provides uniformity to the mixture and facilitates the proper distribution of the cement paste.

- Gravel (or other aggregates): Determines the strength of the structure. The size and shape of the particles affect the structural integrity.

- Water: Activates the hydration process of the cement. Excessive or insufficient water can significantly alter the characteristics of concrete.

Additional components and additives:

To enhance operational characteristics (e.g., frost resistance, setting speed, water resistance), special chemical additives can be used to obtain concrete with specified parameters.

2. Factors influencing the choice of proportions

When determining the optimal proportions of concrete, it is important to consider several key factors:

Purpose of the concrete

- Foundations and load-bearing structures: Require concrete with high strength and density.

- Finishing works: Concrete with lower strength can be used where aesthetic characteristics are a priority.

- Road construction: Requires special properties such as wear resistance and frost resistance.

Properties of components

- Quality of cement: Compliance with standards and freshness of the material.

- Type of sand: Moisture, granulometric composition, and cleanliness.

- Gravel: Size of fractions, shape, and hardness of the stone.

- Water: Clean, free of impurities, with an adequate temperature regime.

Working conditions and mixing technology

- Climatic conditions: Humidity, air temperature, and mixing conditions may require adjustments to the proportions.

- Laying and compaction methods: The quality of the finished structure depends on the correct execution of the technological process.

- Time and method of transporting concrete: Affect its subsequent setting and strength.

3. Calculation of concrete proportions: step-by-step method

For basic construction works, a standard ratio of components is often used. The most popular proportion is 1:2:3:1 (one part cement, two parts sand, three parts gravel, and one part water). However, it is worth remembering that these proportions may vary depending on specific requirements.

Step-by-step calculation instructions

How to correctly calculate the amount of materials for concrete

1. Determining the total volume

Suppose you need 10 m³ of concrete. Next, we calculate how much cement, sand, and gravel is needed.

If the mixture ratio is 1:2:3 (where 1 part cement, 2 parts sand, and 3 parts gravel), then the total number of parts in the mixture is 6.

2. How much cement is needed?

To determine how much cement is needed, divide the total volume of concrete by 6. In our case, this is approximately 1.67 m³ of cement.

3. How much sand and gravel is needed?

- Sand: take twice as much as cement, which is approximately 3.33 m³.

- Gravel: it should be three times more than cement, which is 5 m³.

4. How much water is needed?

The amount of water depends on the type of cement, the moisture of the sand, and the weather conditions. Approximately, you can take the same amount as cement, which is 1.67 m³. However, it is better to add water gradually to avoid making the mixture too runny.

5. Adjusting proportions

- If the sand is wet, use less water.

- In low temperatures, more cement may be needed for better strength.

- If concrete is needed for foundations or load-bearing structures, proportions may vary – consider the recommendations of builders.

With these calculations, you will be able to prepare concrete correctly without complex formulas!

4. Practical example of calculating concrete proportions

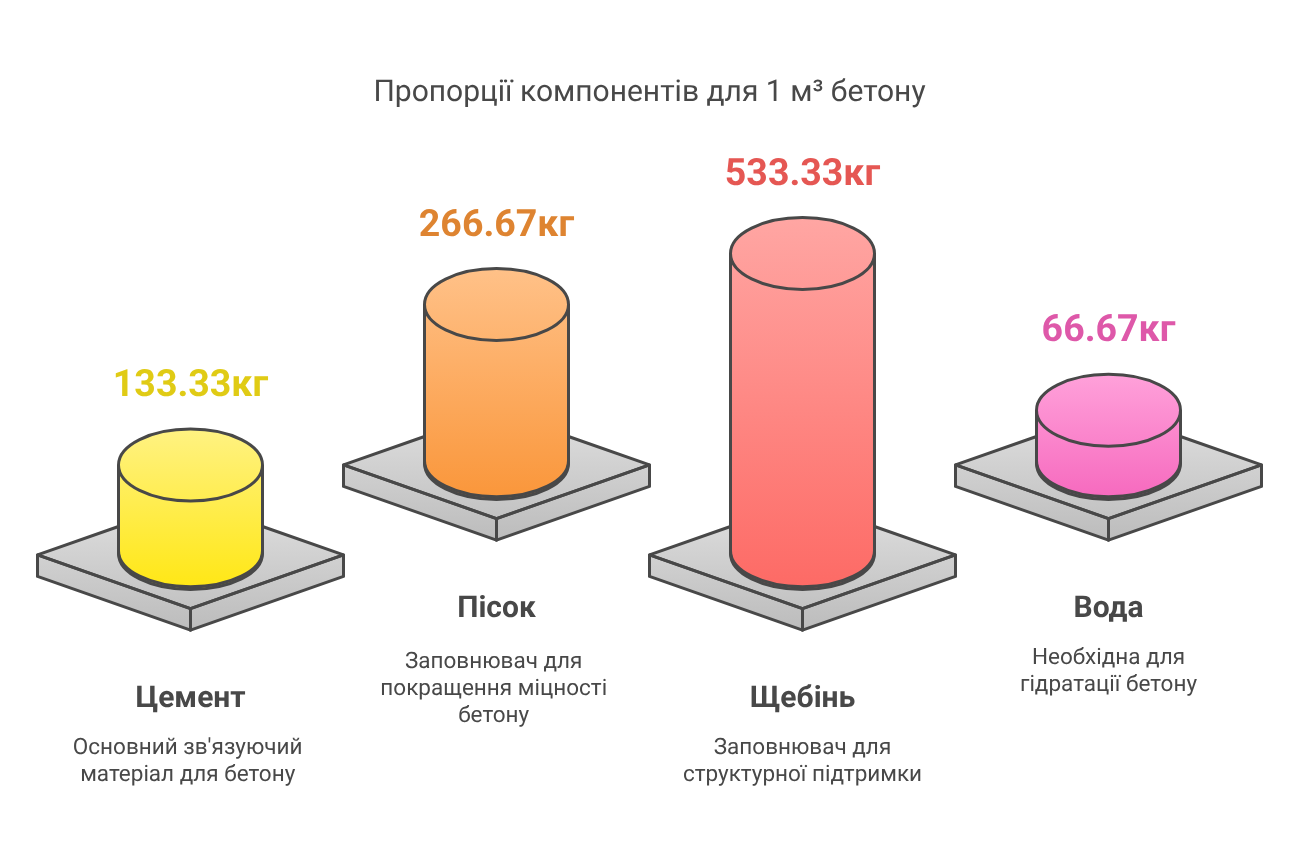

Now let’s calculate the mass of each component based on a volume of 1 m³ of concrete:

-

Mass of cement = (1/7.5) * 1000 kg = 133.33 kg

-

Mass of sand = (2/7.5) * 1000 kg = 266.67 kg

-

Mass of gravel = (4/7.5) * 1000 kg = 533.33 kg

-

Mass of water = (0.5/7.5) * 1000 kg = 66.67 kg

5. Additional recommendations for optimal use of concrete

Quality control of materials

- Checking components:

Always use fresh cement, clean sand, and quality gravel. - Laboratory tests:

Conduct tests on concrete (e.g., compressive strength) to determine compliance with standards.

Adhering to mixing technology

- Mixing time:

Too short a time can lead to uneven distribution of components, while too long can result in loss of required properties. - Compaction:

Ensure proper compaction of the concrete mixture during laying to avoid voids and increase the strength of the structure.

Using special additives

- Plasticizers:

Improve the plasticity of the mixture, allowing for a reduction in water content without losing workability. - Anti-freeze additives:

Used to increase the frost resistance of concrete in cold climatic conditions. - Waterproofing agents:

Provide protection for concrete against water penetration, which is important for structures exposed to moisture.

6. Conclusions

The correctly selected concrete proportion is the key to the successful completion of a construction project. Considering:

- The purpose of the structure,

- The properties of individual components,

- Working conditions and mixing technology,

you can achieve high quality and durability of your construction objects. Do not forget the importance of quality control of materials and the use of special additives to achieve optimal concrete characteristics.

Remember: careful calculation and proper selection of materials will help reduce costs, avoid rework, and ensure the stability of structures for many years.