Composite reinforcement is changing modern construction. It offers a new solution for strengthening buildings. This material is becoming increasingly popular due to its unique properties.

Non-metallic reinforcement is made from high-strength materials. It provides reliability and durability for buildings. Its feature is the ability to withstand large loads at a low weight.

Modern technologies allow for the creation of reinforcement of various diameters. It can range from 2 to 16 mm. This makes it an ideal solution for many construction projects.

Key advantages

- High strength and durability

- Corrosion resistance

- Light weight

- Service life of over 80 years

- Low thermal conductivity

- Ease of installation

- Cost-effectiveness

What is composite reinforcement?

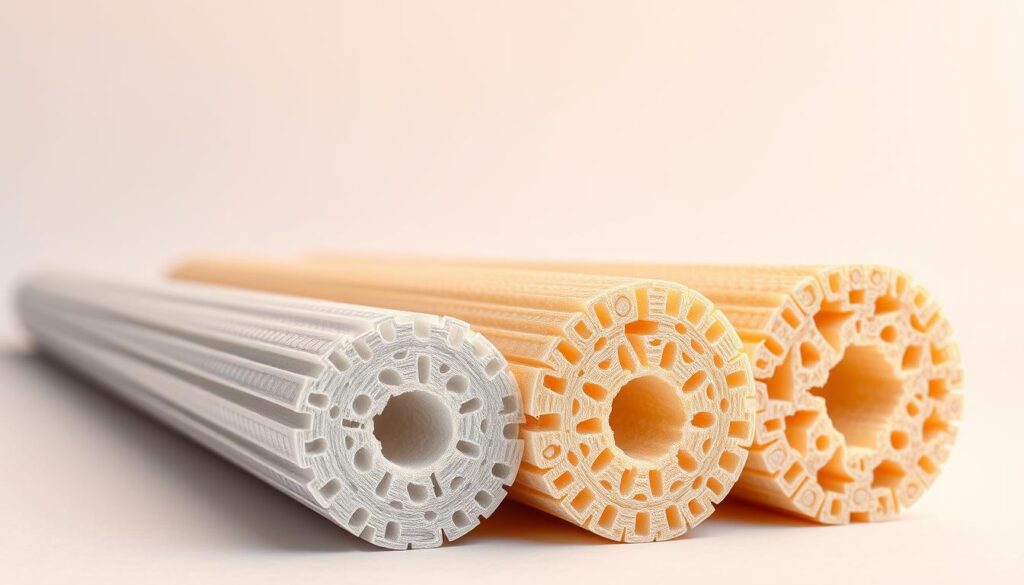

Composite reinforcement is a new material for construction. It consists of reinforced fibers. These fibers have special properties.

This material is distinguished by its structure. It is made from various materials:

- Fiberglass reinforcement

- Carbon reinforcement

- Basalt reinforcement

Main characteristics

Composite reinforcement has many technical advantages:

- High tensile strength

- Lightweight construction

- Corrosion resistance

- Low thermal conductivity

Manufacturing materials

Production uses special polymer fibers. Fiberglass reinforcement is made from glass fibers. Carbon reinforcement consists of carbon threads. And basalt reinforcement is formed from basalt fiber.

Comparison with metal reinforcement

Composite reinforcement surpasses metal in many parameters, particularly in terms of durability and resistance.

Its advantages include:

- Service life of up to 80 years

- Weight is 8 times less than steel

- Tensile strength is 2-3 times higher

Advantages of composite reinforcement

Composite reinforcement has unique properties. It is an innovative material in construction. Fiber composite reinforcement helps solve technical problems.

Lightweight and strength

Flexible reinforcement impresses with its properties. It weighs 8 times less than steel. It also has high tensile strength.

- Lightweight – weighs 8 times less than steel

- High tensile strength – 1000 MPa compared to 390 MPa in steel

- Specific strength up to 3 times higher than steel reinforcement

Corrosion resistance

Fiber composite reinforcement has exceptional protection. It is not subject to corrosion.

- Not subject to corrosion

- Retains properties in water

- Resistant to acids and alkalis

Economic benefits

| Parameter | Composite reinforcement | Steel reinforcement |

|---|---|---|

| Service life | Over 80 years | 40-50 years |

| Transportation cost | Low | High |

| Weight (1000 m) | 20-80 kg | 400-890 kg |

Using composite reinforcement can save up to 50% compared to traditional materials. This makes it very attractive for construction.

“Composite reinforcement is not just a material, it is the technology of the future for the construction industry”

Areas of application for composite reinforcement

Composite reinforcement has changed construction. It combines lightness with high strength. It is used in many fields where reliability is needed.

Construction projects

In construction, composite reinforcement is very popular. It is used:

- In the construction of private houses and cottages

- In the construction of apartment buildings

- In the construction of industrial facilities

- In the construction of agricultural facilities

Infrastructure solutions

Composite reinforcement is ideal for complex projects:

- In the construction of bridges

- In the construction of roads

- In the reconstruction of transport facilities

- In corrosion protection

Manufacturing specialized products

Composite reinforcement is used to manufacture various products:

- Tanks

- Drainage systems

- Communication structures

- Landscape design elements

Composite materials are gaining popularity due to their lightness and strength. They are used in many areas of construction and engineering.

How to choose composite reinforcement?

Choosing composite reinforcement is very important for buildings. It must be reliable and durable. Non-metallic reinforcement requires a special approach when planning.

- Purpose of the structure

- Expected load

- Operating conditions

- Temperature regime

Criteria for selecting composite reinforcement

When choosing non-metallic reinforcement, it is important to pay attention to several parameters:

| Parameter | Characteristic |

|---|---|

| Diameter | 4-16 mm depending on the project |

| Strength | Higher than steel by 3 times |

| Weight | 5-9 times lighter than metal |

Recommendations from professionals

Experts recommend definitely checking the quality of composite reinforcement before use. It is important to pay attention to:

- Uniformity of color

- Absence of cracks

- Availability of certification

- Technical characteristics of the manufacturer

Common mistakes when choosing

The most common mistakes when choosing composite reinforcement include:

- Choosing the cheapest option

- Neglecting operating conditions

- Incorrect diameter calculation

- Ignoring technical requirements

For accurate selection of composite reinforcement, always consult with professional engineers and designers.

Manufacturers of composite reinforcement in Ukraine

Ukraine is rapidly developing in the field of composite reinforcement. There are many high-quality materials for construction. Companies producing fiberglass and carbon reinforcement are particularly well-known.

Famous domestic brands

Ukraine has several large manufacturers of composite reinforcement. They create new solutions for construction. The IMPERATYV company produces over 1 million meters of reinforcement monthly.

- IMPERATYV: production of up to 1 million meters of reinforcement monthly

- UkrArmPlast: manufacturer from Kharkiv, over 10 years of experience

- LIGHTplus®: composite reinforcement with 83% adhesion to concrete

- HARDplus®: reinforcement with 100% adhesion for high loads

Local suppliers

Ukraine has many local manufacturers. They provide quality and affordable products. They offer various types of non-metallic reinforcement, such as glass composite and carbon fiber.

| Manufacturer | Capacity | Features |

|---|---|---|

| IMPERATYV | 60,000 m² of mesh per month | Certificates in Poland, Hungary, Slovakia |

| UkrArmPlast | Production of various types of reinforcement | Own delivery fleet |

How to choose a reliable partner

When choosing a manufacturer, it is important to pay attention to several key criteria:

- Availability of necessary certificates

- Technical characteristics of the product

- Manufacturer’s reputation

- Experience in the market

- Supply and support conditions

By choosing a reliable supplier, you will ensure high quality for construction projects.

Regulations and standards

The production of basalt reinforcement and fiber composite reinforcement in Ukraine is subject to state and European standards. These standards ensure high quality and safety of construction materials.

State requirements for composite reinforcement

Ukrainian standards set clear requirements for composite reinforcement. In particular, diameter, tensile strength, and other technical characteristics are controlled.

| Parameter | Regulatory value |

|---|---|

| Reinforcement diameter | 50-360 mm |

| Tensile strength | From 1000 MPa |

| Fiber material | Basalt, glass, carbon |

European standards

Ukrainian norms are approaching European standards. This opens the way for manufacturers of basalt reinforcement and fiber composite reinforcement to the international market.

Specifications for composites

Compliance with specifications regarding the composition and properties of composite reinforcement is important. Only two Ukrainian manufacturers have international certification confirming the high quality of their products.

Technologies for producing composite reinforcement

Modern production of composite reinforcement is a complex process. It combines new ideas and precise methods. The manufacturing technology includes several key stages. This ensures high product quality.

Production process

Flexible reinforcement is mainly produced by the pultrusion method. This method produces rods with a uniform cross-section and high strength. The main steps are:

- Preparation of raw materials (fibers)

- Impregnation of fibers with polymer matrix

- Shaping of the reinforcement profile

- Heat treatment

- Surface finishing

Raw materials and environmental friendliness

Various materials are used for production. The most common are:

- Glass fiber – the most common type

- Carbon fiber – a very strong material

- Basalt fiber – environmentally friendly

Innovative approaches

Modern technologies create reinforcement with unique properties. Manufacturers apply special coatings and develop new methods. They also work on ecological solutions.

The average productivity of one line is up to 10,000 meters of reinforcement per shift.

Cost of composite reinforcement

Composite reinforcement is becoming increasingly popular in construction. It is economical and has unique properties. Custom reinforcement has different prices depending on many factors.

Main factors affecting the price

The price of composite reinforcement depends on several factors:

- Reinforcement diameter (from 4 to 16 mm)

- Production material

- Manufacturing technology

- Order volume

Price dynamics in different projects

The price of composite reinforcement varies. For example, prices may be:

| Diameter | Length | Price |

|---|---|---|

| 6 mm | 50 m | 474 ₴ |

| 8 mm | 2 m | 48 ₴ |

| 10 mm | 1.5 m | 18 ₴ |

Cost reduction strategies

To reduce costs for reinforcement, one can:

- Plan purchases in advance

- Buy in bulk

- Choose strong reinforcement with minimal safety margin

- Keep an eye on promotional offers

Using composite reinforcement can reduce construction costs by up to 30%.

Frequently asked questions about composite reinforcement

Composite reinforcement raises many questions. Builders and engineers often inquire about its properties. We have provided answers to the most important questions.

Can it be used in winter conditions?

Fiberglass reinforcement withstands cold well. It does not deform with temperature changes like metal. Its properties are very close to concrete.

- Operating temperature range: from -60°C to +80°C

- Resistance to thermal deformations

- No brittleness at low temperatures

What is the warranty on composite reinforcement?

Non-metallic reinforcement is very durable. Its longevity exceeds 80 years. This is significantly more than that of metal reinforcement.

| Indicator | Composite reinforcement | Steel reinforcement |

|---|---|---|

| Service life | Up to 80 years | 20-30 years |

| Corrosion resistance | 100% | Low |

Is composite reinforcement recyclable?

Fiberglass reinforcement can be partially recycled. Manufacturers are working on improving recycling technologies. They take into account environmental requirements.

“The future of construction lies in ecological and durable materials,” say industry experts.

Choosing composite reinforcement means supporting innovation and reliability in construction.

Equipment for installing composite reinforcement

Installing carbon reinforcement requires specialized tools and professional equipment. Modern tools help work with lightweight and strong materials. This is especially important for basalt reinforcement, which has special strength properties.

The main equipment includes cutting tools, special pliers, and tying devices. Protective gear is also important. The lightweight nature of composite reinforcement allows for easy transportation and installation without heavy machinery.

Professional training for installers is very important. It helps to work correctly with composite materials. Students learn cutting, fastening, and installation techniques. This ensures compliance with norms and safety during construction.