Brick is one of the most unique and widely used building materials. There are many types of bricks, each with its own features and advantages, making them suitable for various purposes. 🌟

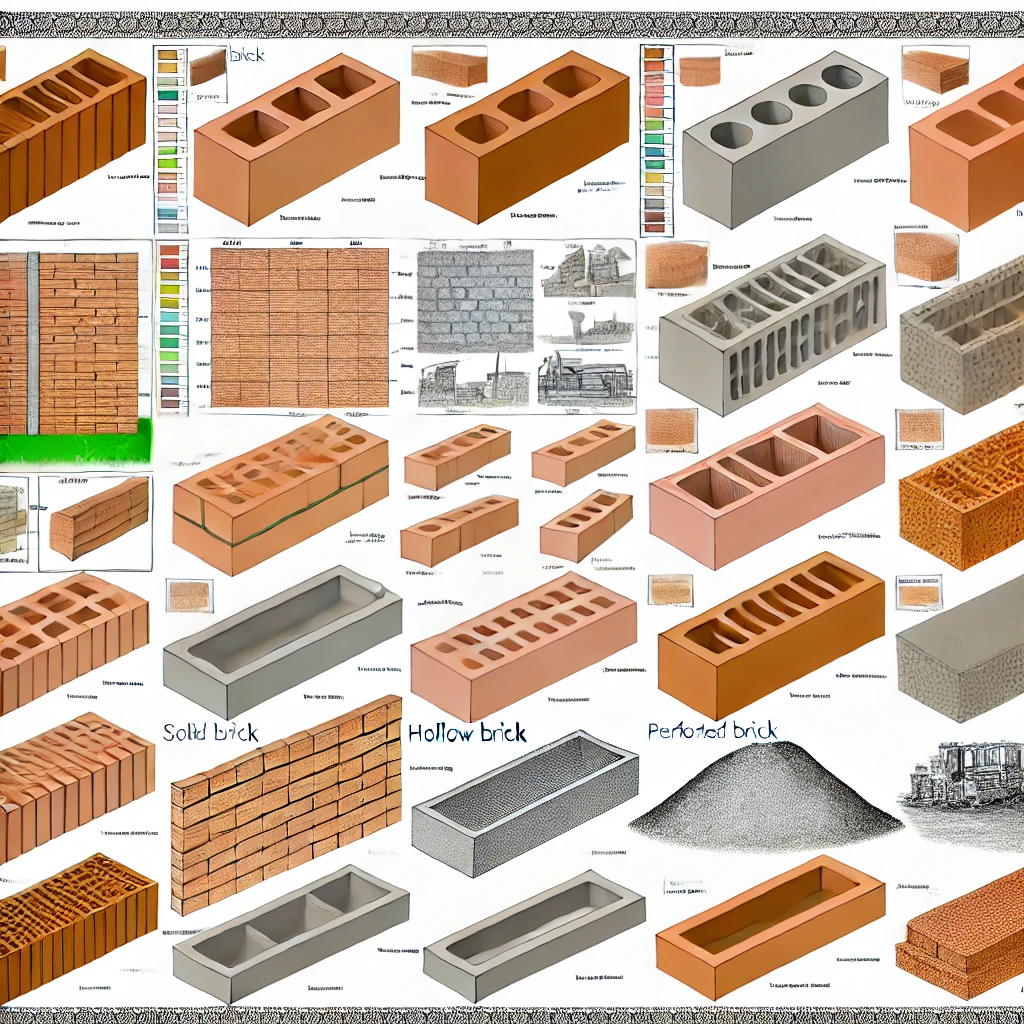

Before delving into the varieties, we note that bricks can be made from different materials. Here are the main types that can be found in construction:

Ceramic brick is a traditional type made from clay. It has high strength, excellent sound insulation, and wear resistance. 🧱

Silicate brick is created by mixing quartz sand and lime. This material absorbs moisture well and is suitable for building walls where thermal insulation is important. 🌡️

Clay brick differs from ceramic brick in its lower heat resistance, but is nevertheless often used in residential construction.

Decorative brick is aesthetically pleasing and is used for finishing facades, interior walls, and fireplaces. It can come in various colors and textures. 🎨

Thermal insulation brick is made from special components that provide enhanced thermal insulation characteristics. It is an ideal choice for energy-efficient homes.

Expanded brick has a porous structure and is used for lightweight constructions. It is very popular in the construction of low-rise buildings. 🏡

These types of bricks can be of standard sizes or non-standard, allowing for expanded possibilities for designers and architects. For example, ceramic bricks typically have dimensions of 250x120x65 mm, but variations are possible. This also applies to other types that can be adapted to specific project requirements.

The choice of a specific type of brick depends on the construction goals, climatic conditions of the region, and budget constraints. For example, ceramic brick would be an excellent choice for building walls, while decorative brick would be suitable for finishing. Thus, due to the variety of brick types, everyone can find the most optimal option for their project. 🔍

Characteristics of Brick

Brick has several key characteristics that determine its use in construction and affect its operational properties. Firstly, there is strength, measured in megapascals (MPa). Compressive and flexural strength are critically important for any building material, as they ensure the stability and safety of structures. For example, ceramic brick can easily withstand large loads, making it a favorite choice for heavy walls.

Secondly, an important characteristic is the porosity of the brick. This indicator affects water absorption, which, in turn, can influence the thermal characteristics of the material. Porous bricks, such as expanded brick, provide good thermal insulation but may be less resistant to moisture. On the other hand, dense bricks, such as ceramic, usually have lower water absorption, which is an advantage in conditions of increased humidity.

The thermal insulation characteristics of bricks also deserve attention. Brick can act as a thermal insulation material, which is an important factor when constructing energy-efficient homes. For example, specially designed thermal insulation bricks have a structure that reduces heat loss, providing a comfortable atmosphere inside the premises. 🏠

Another important characteristic is sound insulation properties, which have a direct impact on living comfort. Brick can absorb sounds if its porosity is sufficiently high, making living spaces cozier and quieter.

“Brick has good sound insulation properties, which helps reduce noise levels from the street.”

The resistance of bricks to environmental influences, particularly fire, moisture, and frost, should not be overlooked. Many types of bricks have high fire resistance, making them ideal for use in the construction of commercial buildings. Ceramic brick, in particular, does not melt even at high temperatures, providing safety for users. Silicate brick, due to its structure, is also resistant to moisture, allowing it to be used in projects related to increased humidity.

It is also necessary to consider the aesthetic characteristics of bricks. The color, texture, and shape of bricks can influence the overall appearance of a building. Decorative brick, in particular, can become an accent in facade design, adding uniqueness and charm. Thus, the diverse characteristics of bricks make them an important material in modern construction, adaptable to any needs and requirements.

Application of Brick in Construction

Brick has a wide range of applications in construction due to its versatility, strength, and aesthetic qualities. Firstly, bricks are used for erecting walls of various types of buildings — from low-rise private houses to high-rise commercial buildings. 🏢 The availability of different types of bricks allows architects and builders to solve any tasks: from creating strong structures to ensuring thermal and sound insulation.

Bricks are also often used for building basements and foundations. For example, silicate brick, due to its moisture resistance, is often chosen for this purpose. In structures with increased reliability requirements, such as industrial facilities or manufacturing plants, ceramic brick appears to be the ideal option due to its strength characteristics. ⚙️

Another important area of brick use is cladding. Decorative brick, due to its aesthetic appeal, can become a bright accent in architecture. It is used for decorating building facades, creating an attractive appearance and protecting the structure from environmental influences. 🎨 Decorative elements can include arches, columns, and other architectural details that add charm and style to the building.

Brick is also popular in engineering structures, such as bridges and dams. Its high strength allows for the construction of reliable structures that are subjected to heavy loads and the effects of natural elements. 🔧 Ceramic brick, for example, often serves as the primary material for erecting load-bearing structures due to its durability and resistance.

It is worth noting that brick is actively used for landscaping. Due to its shape and texture, brick can be used to create various aesthetic elements, such as paths, curbs, flower beds, and rock gardens. 🌿 It is resistant to atmospheric influences, so it will serve for a long time while maintaining its attractive appearance.

Additionally, brick can be part of an energy-saving system. Special thermal insulation bricks are used in the construction of energy-efficient homes, and their application ensures not only reduced heating costs but also improved overall living comfort. 🔋

Among other applications of brick, its use for erecting various small architectural forms, such as fences, gazebos, and barbecues, can be mentioned. Thus, brick not only provides reliability and durability to structures but also adds aesthetic value to any project. 🏡

Advantages and Disadvantages of Brick

Brick has numerous advantages that make it one of the most popular building materials. Firstly, it is characterized by high strength and durability. Due to its ability to withstand large loads, brick ensures the reliability of structures, which, in turn, guarantees the safety of building use. With proper care and maintenance, brick structures can last for decades without significant damage.

Secondly, brick is an excellent thermal insulation material. This aspect is of great importance, especially in cold climates, as it reduces heating costs for premises. High thermal efficiency provides comfortable conditions at any time of the year.

Brick also has good sound insulation characteristics. This is especially important for residential areas, where noise levels can significantly affect living comfort. Due to its mass and structure, brick can effectively absorb sounds, creating a cozy atmosphere in the premises.

Among additional advantages, the aesthetic appeal of brick can be highlighted. The variety of colors, textures, and shapes allows it to be used to create unique architectural solutions. Decorative brick looks interesting in facade design, while classic ceramic brick adds a traditional look to buildings.

However, despite numerous advantages, brick also has some disadvantages. Firstly, there is the cost. The price of brick can be higher than that of other building materials, such as concrete or wood. This can significantly impact the overall project budget.

Secondly, brick has a large weight, which can complicate transportation and installation. In the case of low-rise construction, this is usually not a problem, but for high-rise buildings or large structures, proper conditions for installation must be ensured.

It should also be noted that brick structures have limited moisture resistance, especially in conditions of increased humidity. Porous types of brick may be prone to moisture absorption, which can lead to material damage and reduced thermal and sound insulation properties. Special waterproofing mixtures can be used to prevent these problems.

It is necessary to note that brick can be sensitive to temperature fluctuations, which can lead to cracking. Therefore, when erecting brick structures, it is important to consider climatic conditions and apply appropriate technologies to ensure the necessary level of protection.

Thus, brick, despite some disadvantages, remains one of the most popular and reliable building materials due to its versatility, aesthetic appearance, and positive operational characteristics. The right choice of type and kind of brick, combined with a professional approach to construction, can ensure excellent results in any construction project.

Technological Process of Brick Production

The production of bricks is a complex and multi-stage process that includes several stages, starting from raw material preparation and ending with firing the finished product. The first stage is the extraction and preparation of clay, which is the main raw material for making ceramic bricks. Clay is usually extracted by open-pit mining and then cleaned of impurities such as stones and organic elements. This stage is extremely important, as the quality of the clay directly affects the physical properties of the future brick.

After cleaning, the clay is crushed and mixed with water to form a homogeneous mass. This process is called “preparation of clay mass.” An important part of this stage is maintaining proportions, as this affects the plasticity of the clay, which will influence the shaping of the bricks. Various additives that improve the material’s characteristics, such as sand, lime, or other minerals, may also be added.

The next step is the shaping of the bricks. Special machines are used for this, allowing for the production of bricks in various shapes and sizes. There are several shaping methods: extrusion, pressing, or manual shaping. Depending on the technology, bricks can have different densities and textures. For example, the extrusion method provides high uniformity and evenness of the products.

After shaping, the bricks move to the drying stage. Drying is a critical process to prevent cracks and deformations during firing. Typically, bricks are dried in special chambers or outdoors, where they undergo natural drying, reducing the moisture content in the material to 12-15%. This prepares the bricks for the next stage — firing.

Firing is the process where bricks are subjected to high temperatures in kilns from 800°C to 1200°C. This stage is very important, as physical and chemical changes occur during firing, giving the bricks the necessary strength, waterproofing, and fire resistance. Depending on the type of clay and firing technology, different types of bricks with unique characteristics can be obtained.

After firing is complete, the finished bricks are cooled and checked for compliance with quality standards. Insufficiently quality products are separated and not used in construction. Only bricks that have passed quality control are released to the market for further use. As a result of all these production stages, a wide range of bricks is formed that meets various construction requirements.

Modern brick production technologies also involve the implementation of environmentally friendly approaches, such as recycling secondary raw materials or using alternative fuels in the firing process. This opens new prospects for the development of the brick industry and increases its efficiency. These innovations lead to reduced costs, improved product quality, and environmental preservation. Future generations of projects can benefit from this, as an environmentally sustainable brick industry will ensure the durability and safety of structures.

Prospects for the Development of the Brick Industry

The prospects for the development of the brick industry are determined by both innovative approaches and the constant growth of demand for environmentally friendly and thermally efficient materials. In the modern world, where environmental issues are at the forefront, the brick industry is actively implementing technologies that reduce negative impacts on the environment. The production of bricks using secondary materials, such as waste from ceramic products or industrial waste, is becoming increasingly popular. This approach not only reduces raw material costs but also helps decrease the amount of waste sent to landfills. 🌱

Moreover, there is a growing interest in thermal insulation bricks that can provide energy savings in buildings. In the context of climate change, reducing energy costs is a priority for both consumers and builders. Thermal insulation bricks can be manufactured using cutting-edge technologies that provide enhanced thermal conductivity and water absorption characteristics. This not only improves comfort in homes but also reduces energy bills. ⚡

Modern trends are also aimed at implementing automation and robotics in the brick manufacturing process. This reduces labor costs, increases productivity, and improves quality control at all stages of production. The introduction of modern equipment with computer control makes the process more economically viable and reduces the risk of human error.

An important component of the development of the brick industry is investment in research and development. Innovative materials and technologies, such as bricks with enhanced thermal insulation or bricks made from nanomaterials, open new horizons for the industry. Research projects aimed at creating lighter, stronger, and more environmentally friendly materials have the potential to revolutionize the construction process. 🏗️

Equally important is the promotion of environmentally friendly building practices aimed at reducing the carbon footprint. Consumers are increasingly paying attention to the environmental friendliness of building materials, prompting brick manufacturers to seek paths to sustainable development. Active promotion of “green” building will positively impact the development of the brick industry, increasing demand for eco-friendly solutions.

Thus, the development of the brick industry has bright prospects, focusing on innovation, environmental responsibility, and new technologies. This will not only improve product quality but also meet modern requirements for sustainable development, which is extremely important in our time. Ultimately, the brick industry has the potential to become an important player in creating environmentally friendly and energy-efficient buildings, ensuring comfort and safety for many generations. 🌍