Basalt reinforcement is a new material for construction. It is made from basalt fibers. This material has features that distinguish it from others.

Today, many builders choose basalt reinforcement. It is very strong, lightweight, and does not corrode. It is an ideal choice for many construction projects.

Key Findings

- Innovative material with unique properties

- High corrosion resistance

- Lightweight and easy to install

- Suitable for various types of construction projects

- Economically advantageous solution for modern construction

What is basalt reinforcement?

Basalt reinforcement is a new material for construction. It is quickly becoming popular. It is made from basalt fiber, which gives it special properties.

Modern technologies create reinforcement with outstanding characteristics. The main features of basalt reinforcement include:

- Increased strength compared to traditional materials

- Low weight of structures

- High resistance to aggressive environments

- Long service life

Unique characteristics of the material

Basalt reinforcement has exceptional properties. It is 4 times lighter than steel and 3 times stronger. Its corrosion protection ensures durability.

“Basalt reinforcement is a revolutionary material that changes approaches to modern construction”

Advantages over traditional materials

Basalt reinforcement withstands extreme loads and temperature changes. Its coefficient of thermal expansion is almost the same as that of concrete. This prevents cracking.

- Not prone to corrosion

- Resistant to aggressive chemical environments

- Has low thermal conductivity

- Cost-effective in the long term

The market for basalt reinforcement is rapidly growing. By 2030, it will reach 60 million USD. This indicates its potential and popularity in construction.

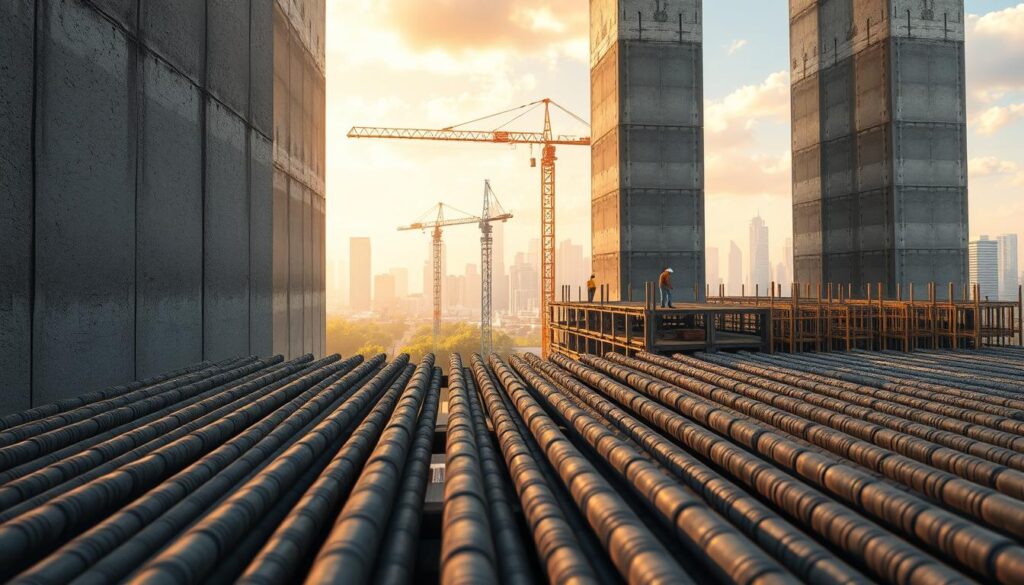

Application of basalt reinforcement in construction

Basalt reinforcement has changed construction. It provides unique solutions for various projects. Its feature is durability and resistance to extreme loads.

Residential construction

In the residential sector, basalt reinforcement has significant advantages:

- High resistance to temperature fluctuations

- Low thermal conductivity

- Corrosion protection

- Lightweight structures

Industrial facilities

For industrial construction, basalt reinforcement has specific features:

| Parameter | Characteristic |

|---|---|

| Tensile strength | 1000-1300 MPa |

| Young’s modulus | 70 GPa |

| Weight | 5 times lighter than steel |

Bridges and other engineering structures

When constructing bridges and complex structures, basalt reinforcement provides maximum reliability. Its thermal expansion is almost the same as that of concrete, which reduces the risk of destruction.

Basalt reinforcement can withstand aggressive environments. It ensures the durability of structures for decades.

Manufacturing technology of basalt reinforcement

Basalt reinforcement is a unique material for construction. It has extraordinary properties. The production process includes complex stages that ensure its high chemical resistance.

- Preparation of high-quality basalt raw materials

- Melting of rock at temperatures above 1500°C

- Formation of continuous fibers

- Drawing and reinforcing fibers

- Application of protective coating

Manufacturing processes

The technology for producing basalt reinforcement requires precise control. Melting of basalt rock occurs in special furnaces. There, the temperature reaches critical values.

The molten mass passes through die plates. It forms thin continuous fibers.

Raw materials for production

Only natural volcanic rock – basalt – is used for production. This raw material has:

- High temperature resistance

- Natural chemical inertness

- Environmental safety

- Absence of harmful impurities

Basalt reinforcement can withstand extreme loads. It maintains stable characteristics over a long time.

Comparison of basalt and steel reinforcement

The choice of reinforcement material is important for construction. Basalt reinforcement has features that distinguish it from steel.

Strength and weight

Basalt reinforcement is very strong but weighs less. Environmentally friendly material has unique properties:

- Tensile strength is 2 times higher than steel reinforcement

- Density is 4 times lower than steel

- Temporary resistance to stretching: 700-1300 MPa (compared to 360 MPa in steel)

Corrosion resistance

Basalt reinforcement is very resistant to corrosion. Low weight of the material helps with quick installation.

Cost and economy

The market for composite reinforcement is rapidly growing. By 2027, it will reach 837.1 million USD, growing at 9.3% annually.

| Indicator | Basalt reinforcement | Steel reinforcement |

|---|---|---|

| Durability | Up to 80 years | 30-50 years |

| CO2 emissions during production | Low | High |

| Thermal conductivity | Much lower | High |

Choosing basalt reinforcement means an economical solution for construction.

Installation of basalt reinforcement

Basalt reinforcement is increasingly used in construction. Proper installation is important for the strength of buildings.

- Checking the surface and site conditions

- Selecting the diameter of the reinforcement

- Preparing tools and materials

Preliminary preparation

Before starting work, preparatory actions must be taken. Better preparation means a stronger structure.

- Cleaning the surface from dirt

- Checking the geometry of the foundation

- Marking the place for reinforcement

Laying technique

When laying, special methods should be followed:

- Arranging rods according to the project

- Fixing with special fasteners

- Checking the evenness of the arrangement

Connection requirements

Connecting basalt reinforcement requires attention. Proper connection ensures strength:

- Connection strength up to 1000 MPa

- Temperature range from -70°C to +100°C

- Service life up to 100 years

These recommendations should be followed for the strength of buildings.

Regulatory documents and standards

Basalt reinforcement in construction is regulated by important documents. They ensure strength and protection against corrosion. This guarantees high quality and reliability of buildings.

Ukraine has state standards for basalt reinforcement. They cover various aspects of production and use:

- DSTU B V.2.7-312:2016 – technical conditions for basalt reinforcement

- DSTU 9065:2021 – general technical conditions for composite reinforcement

- DSTU-N B V.2.6-185:2012 – recommendations for designing structures

State standards of Ukraine

State standards define requirements for basalt reinforcement. They include strength, safety, and environmental friendliness. DSTU B V.2.7-312:2016 establishes criteria for reinforcing concrete structures.

International standards

International standards complement domestic ones. They provide increased strength and reliability of basalt reinforcement. They meet modern technologies and construction experience.

Basalt reinforcement meets the highest quality and safety standards in modern construction.

Advantages of using basalt reinforcement

Basalt reinforcement has unique properties that make it ideal for construction. Reinforcement from Armalit stands out for its durability and high resilience.

Environmental friendliness of the material

The production of basalt reinforcement is significantly more environmentally friendly than metal. It has several key environmental advantages:

- Has minimal negative impact on the environment

- Due to the use of natural raw materials

- Produces fewer emissions during production

Durability of structures

Basalt reinforcement ensures the reliability of buildings. Statistics confirm its exceptional nature:

| Parameter | Indicator |

|---|---|

| Tensile strength | 2.5 times higher than metal |

| Weight | 5-9 times lighter |

| Corrosion resistance | Practically not prone to corrosion |

Resource savings

Basalt reinforcement significantly reduces construction costs. Economic efficiency can range from 20% to 70% due to:

- Reduction of logistics costs due to lightweight

- Reduction of installation costs

- Long service life without additional costs

Basalt reinforcement is an innovative solution. It combines environmental friendliness, durability, and economic efficiency.

Cost of basalt reinforcement

Basalt reinforcement is becoming increasingly popular. Its properties, such as non-combustible materials and high chemical resistance, attract builders. Many are also interested in the economic efficiency of its use.

Factors influencing the price of basalt reinforcement

The price of basalt reinforcement depends on several factors:

- Diameter of the rod

- Length and configuration

- Quality of chemical treatment

- Manufacturer and supplier

Price table for basalt reinforcement

| Diameter (mm) | Price (UAH) | Weight (kg) |

|---|---|---|

| 4 | 4.20 | 25 |

| 6 | 6.40 | 40 |

| 8 | 12.96 | 65 |

| 10 | 17.71 | 85 |

| 12 | 23.45 | 110 |

| 14 | 40.00 | 135 |

Basalt reinforcement is more expensive than fiberglass. But its features justify the price.

Installation costs

The installation of basalt reinforcement is economical:

- Reduction of the weight of structures

- Acceleration of construction work

- Minimal costs for additional equipment

- Absence of corrosion damage

Basalt reinforcement reduces construction costs. It has a long service life and requires minimal maintenance costs.

User reviews of basalt reinforcement

Basalt reinforcement attracts builders and engineers with its features. Research and real reviews help better understand its advantages and possible issues.

Positive impressions from use

Experts note many advantages of basalt reinforcement:

- Lightweight material facilitates transportation and installation

- High corrosion resistance

- Environmentally friendly material without harmful impurities

- Long service life

Challenges and warnings

Users also highlight some issues:

- Higher initial cost compared to traditional steel reinforcement

- Need for special installation skills

- Limited practice of widespread application

“Basalt reinforcement is an innovative solution that is gradually changing approaches in construction,” note professional engineers.

| Criterion | Basalt reinforcement | Steel reinforcement |

|---|---|---|

| Weight | Light | Heavy |

| Corrosion resistance | High | Low |

| Environmental friendliness | High | Low |

Experts believe that the popularity of basalt reinforcement will grow. This will be due to its features and the improvement of production technologies.

Errors in the installation of basalt reinforcement

The installation of basalt reinforcement requires attention and a professional approach. Minor mistakes can lead to serious problems. Let’s consider the most common technical errors when working with composite reinforcement.

The most common problems during installation

Experts highlight several critical mistakes during the installation of basalt reinforcement:

- Improper storage of materials

- Failure to adhere to temperature conditions

- Poor quality connection of reinforcement elements

- Violation of laying technology

How to avoid typical mistakes

Professional work with basalt reinforcement requires adherence to rules:

- Quality control of materials

- Strict adherence to instructions

- Use of specialized tools

- Preliminary surface preparation

Composite reinforcement has features that differ from metal. Qualified installation will help avoid deformations and ensure reliability.

Innovative solutions using basalt reinforcement

Basalt reinforcement is changing construction. It offers new solutions with increased strength and corrosion protection. These technological breakthroughs create effective materials.

Latest technological approaches

Modern innovations in the field of basalt reinforcement open new opportunities:

- Increased strength of the material allows for the creation of lighter and more resilient structures

- Corrosion-resistant material ensures a long service life without additional protection

- Reduction of the weight of structures by up to 6 times compared to metal counterparts

Successful implementation projects

Practice confirms the high effectiveness of basalt reinforcement in various fields:

- Construction of bridge crossings

- Erection of industrial facilities

- Renovation of historical buildings

The economic efficiency of using basalt reinforcement is 20-70%. This makes it a very attractive solution for modern construction.

Questions and answers about basalt reinforcement

Basalt reinforcement raises many questions. This concerns builders and private developers. We have gathered the most relevant questions about this material and provided expert answers.

The most common questions about basalt reinforcement

We will consider key aspects. This interests consumers regarding its durability and properties.

- How much does basalt reinforcement cost?

- How to determine the quality of the material?

- Where is it best used?

- What are the advantages over metal reinforcement?

Expert consultations

Construction industry specialists provide professional advice on basalt reinforcement:

- Check the quality certificates of the material

- Consider the operating conditions of the structures

- Follow the installation technology

| Parameter | Basalt reinforcement | Steel reinforcement |

|---|---|---|

| Service life | Up to 100 years | 30-50 years |

| Corrosion resistance | High | Low |

| Weight | Light | Heavy |

Basalt reinforcement has unique characteristics. This makes it attractive for modern construction. Durability of the structure and high strength distinguish it from other materials.

Experts recommend using basalt reinforcement in projects where reliability and long-term operation are important.

Disadvantages of basalt reinforcement

Basalt reinforcement has its advantages, but also limitations. Its features are important to understand before use. Specialists advise thoroughly studying all aspects of construction design.

The main disadvantages of basalt reinforcement include:

- High production costs

- Limited ability to withstand significant loads

- Difficulty in connecting individual elements

- Low elasticity compared to metal counterparts

Specific limitations of the material

Chemical resistance of basalt reinforcement does not imply its universality. It has limitations regarding temperatures and mechanical loads.

| Parameter | Value |

|---|---|

| Minimum working temperature | -260°C |

| Maximum working temperature | +600°C |

| Tensile density | 4840 MPa |

Alternative materials

For some projects, it is better to choose other materials:

- Steel reinforcement

- Fiberglass reinforcement

- Composite materials

- Polypropylene reinforcement

Expertise and certification

The expertise of basalt reinforcement is very important for its quality and safety. Specialists conduct detailed studies. They check physical properties such as diameter and strength.

Certification is based on the standards DSTU-N B V.2.6-185:2012 and GOST 31938-2012. Experts conduct tests on control samples. They determine strength and check compliance with standards.

Assessment of compliance of reinforcement with environmental norms is very important. Specialists check various parameters. This ensures the reliability of the material in construction.