Austenitic stainless steel is a special material for construction. It is very useful in modern industry. Chromium-nickel steel has very high corrosion resistance and special properties.

This material contains more than 18% chromium and more than 8% nickel. This makes it very special among other metals. Austenitic stainless steel withstands very aggressive conditions, making it highly valuable in various industries.

Key points

- High corrosion resistance

- Unique metal structure

- Wide industrial application

- Resistance to aggressive environments

- High manufacturability

What is austenitic stainless steel?

Austenitic stainless steel has unique properties. It is very valuable in many industries. It is one of the most common and skillful types of metal alloys.

Definition of austenitic steel

Austenitic stainless steel is a high-quality alloy. It has a unique crystalline structure. Its features include:

- Chromium content from 18% to 25%

- Nickel content from 8% to 20%

- Non-magnetic properties

- High corrosion resistance

Alloying elements give the steel special characteristics. This makes it very strong and resistant to external influences.

History of origin

The development of austenitic stainless steel began in the 1930s. The first studies aimed to create a metal with improved properties.

| Period | Achievements |

|---|---|

| 1930s | First experimental steel “R-193” |

| 1940s | Development of A286 steel with molybdenum |

| 1950s | Improvement of composition and properties |

Scientists continued to experiment with alloying elements. They reduced the carbon content and added new components. This increased the corrosion resistance of the metal.

Main components of austenitic steel

Austenitic steel consists of many important elements. Each of them plays a role in forming the properties of the metal.

Austenitic steel contains many alloying elements. They greatly influence its properties.

Nickel: the main structure stabilizer

Nickel is a key element in chromium-nickel steel. It helps:

- Create an austenitic structure

- Increase corrosion resistance

- Increase the plasticity of the metal

In austenitic steel, nickel is present at 8-11%. This creates a stable structure at room temperature.

Chromium: the protective barrier of the metal

Chromium is an important element for corrosion protection. The minimum chromium content is 10.5%.

Chromium is present in steel at 16-20%. This provides strong protection against corrosion.

Additional alloying elements

The composition may include:

- Molybdenum

- Titanium

- Niobium

- Nitrogen

These elements enhance strength and corrosion resistance. They also improve other properties of the steel.

Properties of austenitic stainless steel

Austenitic stainless steel is a unique material. It accounts for about 70% of all stainless steel used in the world.

Its properties depend on the chemical composition and structure. The steel contains at least 16% chromium and 6% nickel. This provides its unique characteristics.

Corrosion resistance

Corrosion resistance is a major advantage of austenitic steel. Its protection is based on the formation of a thin oxide layer. This layer prevents the metal from deteriorating.

- The minimum chromium content for corrosion protection is 10.5%

- The addition of nickel increases resistance to aggressive environments

- The ability to withstand extreme temperatures

Mechanical properties

Strength of austenitic steel is very important. It determines its wide application. The main mechanical parameters include:

| Parameter | Value |

|---|---|

| Tensile strength | 510-700 MPa |

| Yield strength | ≥200 MPa |

| Elongation | ≥40% |

| Hardness | ≤180 HB |

Austenitic steels have exceptional toughness and increased strength. This is especially noticeable at low temperatures. Their unique structure allows them to withstand large loads without breaking.

Comparison with other types of stainless steel

There are many varieties of stainless steel in the world. Each has its own features and areas of application. Let’s look at their characteristics, advantages, and differences.

Ferritic steel: structural features

Ferritic stainless steel has a unique magnetic structure. Its main characteristics:

- High corrosion resistance in simple environments

- Lower strength compared to austenitic steel

- Lower production cost

Martensitic steel: properties and applications

Martensitic steel is distinguished by its special ability to harden. Its key characteristics:

- High hardness and strength

- Ability to be heat treated

- Limited corrosion resistance

Austenitic stainless steel shows the best corrosion resistance and strength. Its composition, which includes chromium and nickel, provides exceptional corrosion protection.

Applications of austenitic stainless steel

Austenitic stainless steel is very versatile. It is ideal for various industries. Manufacturing technologies ensure its high quality.

In the food industry, it has become a real breakthrough. Manufacturers love it because it withstands aggressive environments. It is also easy to clean.

Industrial applications

Key areas of use include:

- Medical equipment for precise research

- Chemical production

- Oil refining industry

- Food machinery

Marine and household constructions

In marine constructions, austenitic steel is very corrosion-resistant. Over 70% of structures in ports and marine facilities are made from this material.

In households, it is used for:

- Kitchen appliances

- Household appliances

- Designer interior elements

Austenitic stainless steel is not just a material; it is a technological solution for the modern world.

Processing technologies for austenitic steel

Austenitic stainless steel has unique processing methods. They ensure its high weldability and strength. Specialists have developed effective methods for working with this material.

Welding austenitic steel

Welding austenitic steel has its peculiarities:

- High weldability of the material

- Special electrodes

- Temperature control

For the best strength of welds, it is important to adhere to technological modes.

Machining on machines

Machining on machines includes several stages:

- Turning with special tools

- Milling with cooling

- Grinding with minimal pressure

Each method requires attention to preserve the material and its properties.

| Processing method | Features | Purpose |

|---|---|---|

| Welding | High precision | Joining parts |

| Turning | Minimal load | Shaping surfaces |

| Grinding | Cleanliness of processing | Smoothness |

Choosing the right technology will preserve the unique properties of the steel.

Advantages of austenitic stainless steel

Austenitic stainless steel has unique properties. This makes it a very interesting material for many industries. Its durability and ability not to corrode ensure a long service life.

Let’s consider the key advantages of this metal:

- High corrosion resistance

- Long service life

- Attractive appearance

- Surface treatment capability

Durability as a main advantage

Durability of austenitic steel is related to its chemical composition. Chromium and nickel create a protective layer. This layer prevents corrosion and destruction of the material.

Aesthetic characteristics

Corrosion-resistant steel also has an attractive appearance. Smooth surface and shine make it popular in design.

| Characteristic | Value |

|---|---|

| Service life | 30-50 years |

| Corrosion resistance | High |

| Aesthetic appeal | Excellent |

By choosing austenitic stainless steel, you get a reliable material. You also get an aesthetic solution that will last for decades.

Disadvantages of austenitic stainless steel

Austenitic steel is very corrosion-resistant, but it has its limitations. It is important to understand these limitations before using it. Every material has its peculiarities, and austenitic steel is no exception.

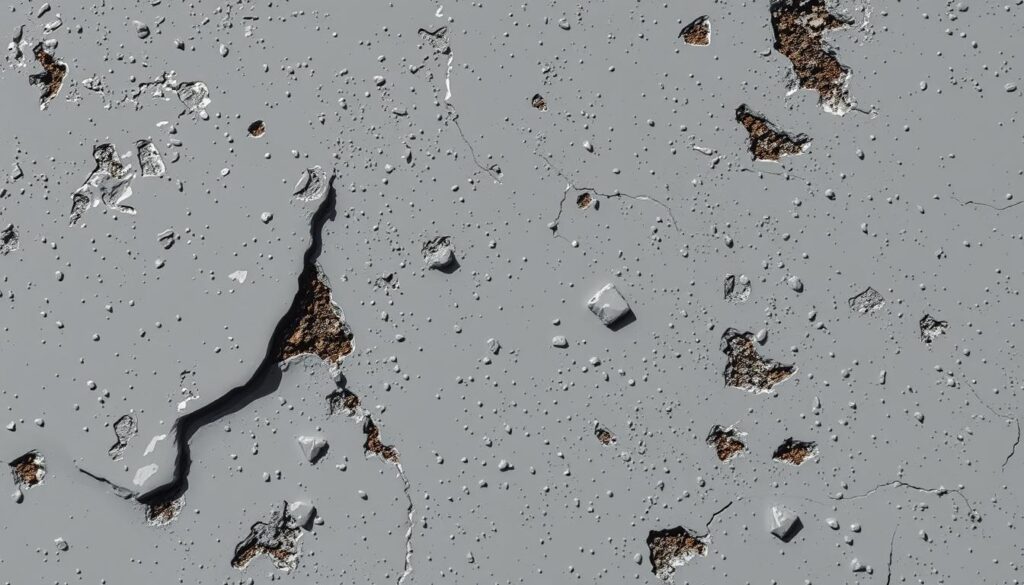

Vulnerability to intergranular corrosion

The main problem of austenitic steel is its microstructure. Under certain conditions, intergranular corrosion can occur. This reduces the durability of the material:

- Formation of chromium carbides at grain boundaries

- Reduced corrosion resistance with prolonged heating

- Risk of structural failure in aggressive environments

Economic limitations

Austenitic stainless steel is very expensive. This is due to the use of costly alloying elements:

| Element | Impact on cost |

|---|---|

| Nickel | Increases the price of the material |

| Chromium | Increases corrosion resistance |

| Molybdenum | Improves mechanical properties |

Experts recommend carefully assessing the economic feasibility of using austenitic steel in each specific case.

Despite its disadvantages, austenitic steel is still very popular. This is due to its unique properties and wide range of applications.

Prospects for the implementation of austenitic steel

Modern technologies open new opportunities for austenitic steel. Its durability makes it a valuable material for many industries.

Latest manufacturing technologies

Research shows that austenitic steel has great potential. It contains a lot of chromium and nickel. This allows it to withstand very high temperatures.

- Temperature range up to 2000 degrees Celsius

- High resistance to oxidation

- Excellent corrosion resistance indicators

Environmental solutions

Austenitic steel is very useful for marine constructions. It stands well against aggressive environments. This is very important for hydraulic engineering.

| Characteristic | Indicator |

|---|---|

| Corrosion resistance | High |

| Temperature resistance | Up to 2000°C |

| Chromium content | 20-25% |

| Nickel content | 10-20% |

The use of austenitic steel helps create more durable and clean engineering solutions. This meets the requirements of sustainable development.

How to choose austenitic stainless steel?

When choosing chromium-nickel steel, it is important to pay attention to its characteristics. Standard austenitic stainless steel of series 300 has 8-11% nickel and 16-20% chromium. This ensures its excellent corrosion resistance.

The most common grades include steel 304 for general use. Steel 316 has increased resistance to aggressive environments. And steel 321 is stable at high temperatures. The choice depends on the operating conditions and technical requirements.

For the food, chemical, and medical industries, it is better to use steels with high corrosion resistance, such as 316L. In construction, preference is given to steels with a shiny surface and aesthetic appearance.

When making a final choice, it is important to consider the temperature regime and the possibility of contact with aggressive substances. It is also important to consider mechanical loads and the economic feasibility of using a specific grade.